Tripotassium Orthophosphate: Insight Into an Essential Inorganic Compound

Historical Development

Agriculture and industrial chemistry saw a real leap with the discovery and use of phosphates, and tripotassium orthophosphate stakes its place among these. Large-scale use ramped up in the mid-20th century as fertilizer technology picked up steam. As I learned during my stint working with a fertilizer importer in the late 90s, intense interest always surrounds efficient potassium sources. Early chemists worked out how dissolved phosphates support plant growth, which led to government-backed programs pushing phosphate products. Tripotassium orthophosphate found a role here, not just for farms, but in water treatment plants, food processing, and even as a key player in laboratory buffers and detergent building. Advances in chemical engineering delivered easier purification methods, allowing for higher volumes and accessibility. Scientists kept tweaking crystal forms and purity levels, fueling broader adoption.

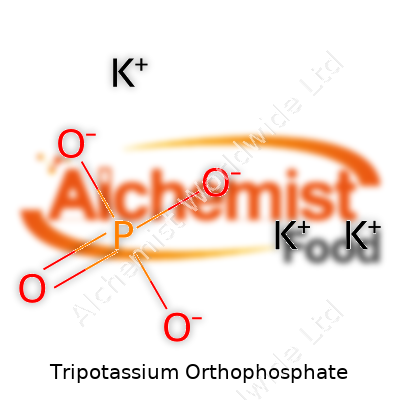

Product Overview

Every bag of tripotassium orthophosphate starts with the raw, punchy mineral: potassium carbonate or hydroxide blended with pure phosphoric acid. What you get is a white, non-hygroscopic powder with a strong alkaline punch—think of how baking soda feels, but even more potent and "soapy". Its solubility makes it a go-to for several industries, including food processing, fertilizers, water treatment, and cleaning products. In my experience, manufacturers often choose this compound not just for potassium content, but for its reliability in buffering solutions and keeping pH levels steady when other options fall short. The stuff rarely clumps or degrades under even rough storage, so suppliers like it for warehouse convenience as much as for chemistry.

Physical & Chemical Properties

Tripotassium orthophosphate holds the formula K3PO4. The powder easily dissolves in water, releasing potassium and phosphate ions almost instantly. The compound creates distinctly alkaline solutions, with a pH around 12 for concentrated mixtures—this property gives it solid cleaning and neutralizing power. Its melting point clocks in at 1340°C, far beyond usual industrial process temperatures. No strong scent, little in the way of dusting, and minimal impact on taste when used properly. During some work with beverage plants, I’ve watched technicians depend on its fast, clear dissolving to keep pipelines scum-free and to prevent calcium scaling, proving the value of chemical predictability.

Technical Specifications & Labeling

Regulations in North America, Europe, and Asia all set tight controls on food-grade and technical-grade tripotassium orthophosphate. Detailed labels need batch number, purity percentage (often exceeding 98% K3PO4 for technical grades), solubility specs, country of origin, and certifications. One longstanding distributor taught me the hard lesson: a missing certificate or incorrectly listed heavy metal limit can grind exports to a halt. Labels for food applications list all possible additives, and several jurisdictions expect documented absence of toxic impurities like arsenic or cadmium, even at levels below 1 ppm. Kosher, Halal, and ISO documentation top the request lists from global buyers.

Preparation Method

Large-scale synthesis starts with potassium carbonate or potassium hydroxide, usually sourced from brine processing, mixed with industrial-strength phosphoric acid. A controlled reaction heats the solution, drives off water, and triggers a predictable color shift as crystals form. Chemists filter, cool, and dry the resulting product, often repeating purification for high-spec food or pharma batches. Smaller-scale batches sometimes use potassium chloride, but this route needs extra washing to avoid sodium cross-contamination. I’ve watched laboratory technicians fiddle repeatedly with pH, since even a small drift can spark unwanted byproducts or reduce the plant’s output.

Chemical Reactions & Modifications

React tripotassium orthophosphate with strong acids and you’ll release phosphate ions, forming dipotassium or monopotassium phosphates. Pair it with ammonium salts, and you land ammonium phosphates, staples in both fertilizer and flame-retardant lines. Mix in transition metals and you can produce customized phosphate coatings for rust prevention or battery technology. A few plant operators I’ve known rely on its strong base strength for rapid neutralization of acid waste, and environmental engineers blend it into formulas for phosphate glass production, where slight tweaks in the ratio change the thermal and electrical behavior of glass products. Its flexibility matters—a simple alteration during production slides you along the whole family of potassium phosphates.

Synonyms & Product Names

In labs, this chemical often goes by potassium phosphate tribasic, tribasic potassium phosphate, or E340(iii) in food labeling. Some older texts call it tripotassium phosphate. Large distributors sometimes push it under brand names, but technical buyers scan for K3PO4 on the certificate. Confusingly, product names shift between countries—“potassium triphosphate” surfaces in some markets even though it technically means something else. I’ve seen paperwork ruined by a careless tick in the wrong “potassium phosphate” box, so keeping trade names lined up with chemical reality always saves time and budget.

Safety & Operational Standards

Handling tripotassium orthophosphate calls for personal protective gear—gloves to dodge the strong base, goggles to prevent splashes from burning the eyes, and dust masks during manual transfer operations. SDS sheets lay out the risks: irritation to eyes, skin, and lungs, with higher exposures causing chemical burns. Long-time chemical warehouse staff set up splash-proof storage in dry, separate bays, and exclude any contact with acidic materials to avoid accidental reactions. In my plant visits, seasoned operators never take shortcuts: they keep close tabs on bulk containment and ventilation systems to avoid fine dust in the air, sticking to protocols around labeling and compatibility charts—rules learned the hard way by previous generations.

Application Area

Fertilizers dominate the market, since potassium and phosphorus both rank high as essential plant nutrients. Agronomists rely on its purity; a tiny dose in hydroponics can stabilize nutrient broths that boost root health. Water treatment operators value its ability to soften water and prevent mineral scaling in pipes. Food technologists chalk it up as a regulator and emulsifier for cheese, meat, and beverage blends—sodium-reduced products use potassium salts to hit health targets. Industrial applications demand it for detergent blends, corrosion inhibition, and boiler water conditioning. My own hands-on work with water utilities showed that, without this compound, deposits can bring a city’s water flow to a crawl.

Research & Development

Academic labs regularly experiment by tweaking orthophosphate ratios for specialized fertilizers or low-sodium food products. Recently, research into electrochemical energy storage flagged potassium phosphates—including tripotassium orthophosphate—as promising materials for electrode stabilization and ionic conductivity. Microbiologists look at antimicrobial effects, hoping for new food safety tools and biodegradable cleaning agents. Food designers test it for texturizing vegan cheeses or meat alternatives, hunting for clean labels that satisfy both chemists and consumers. At a research expo I attended, I saw lively debate over the overlooked role of potassium phosphates in minimizing sodium intake, with new prototypes for heart-healthy foods making their debut.

Toxicity Research

The compound’s toxicity relates closely to its alkalinity; it burns tissue on contact at high concentrations. Ingest too much without dilution, and the gut reacts harshly. Regulatory reviews show safe limits for human consumption, capping daily intake to a few dozen milligrams per kilogram for food uses. Chronic overconsumption—rare since the taste throws you off—can strain kidneys and throw off electrolyte balance. Water solubility means environmental spills cause localized spikes in phosphate levels, which trigger algal blooms and harm aquatic life. The EPA and European Commission alike target tight controls and quick spill response. I learned early in my career to never skip a containment audit; a single small leak in a food plant can mean a week of lost production and costly fines.

Future Prospects

Sustainability questions hang over all phosphate products, since overuse leads to wastewater and runoff headaches. Yet I see new opportunities developing for recycled phosphates pulled from sludge and wastewaters. Next-generation fertilizers could pair tripotassium orthophosphate with slow-release carriers, reducing over-application and runoff risk. Food scientists increasingly search for less processed, low-sodium additives, positioning potassium orthophosphates as contenders for healthier product lines. Researchers keep chipping away at efficient, energy-saving synthesis processes; some pilot plants now use electrochemical routes that cut carbon emissions and material losses. Looking ahead, regulation will tighten on environmental releases and personal exposure, but technical improvements and real innovation should allow safer, more eco-friendly manufacturing and usage across the supply chain.

What is Tripotassium Orthophosphate used for?

What exactly is Tripotassium Orthophosphate?

Tripotassium orthophosphate shows up in more of our world than many folks realize. It’s a white, crystalline powder that delivers a hefty dose of potassium and phosphate—two nutrients both humans and industries get a lot of use from. In my own years working in food science and poking around various packaging plants, I kept bumping into this stuff under ingredient lists, fertilizer labels, and cleaning formulations. Most people have probably never thought twice about it, but there’s a reason it keeps showing up.

Food Industry Applications

Food manufacturers rely on tripotassium orthophosphate for several solid reasons. It acts as a stabilizer and an emulsifier—think of baked goods staying soft and processed cheeses that blend smoothly instead of turning greasy or gritty. Sports drinks and instant beverages often use it to beef up the potassium levels because many of us don’t get enough from fruits and vegetables alone. The FDA counts it among those additives considered generally recognized as safe, though it still makes sense to keep an eye on how much enters your daily routine, especially for folks on kidney diets or with specific health conditions. Overdoing phosphate additives in processed foods may have risks for certain groups, like people with advanced kidney issues. Manufacturers carry the responsibility here, balancing function with health.

Role in Agriculture

Tripotassium orthophosphate also pops up in the world of farming. The potassium in it supports plant growth and boosts yields, especially in soils that run low on nutrients. Many growers turn to it as a way to quickly feed their crops with a form of potassium that dissolves easily and mixes right into irrigation systems. Fertilizer blends sometimes add it to push up potassium content during critical growth phases. Around rural farms and even some home gardens, you might spot big bags with “potassium phosphate” stamped on them. But like any fertilizer, too much leads to runoff, risking waterways and their ecosystems. The answer sits with close supervision, regular soil tests, and seeing fertilizers as tools, not a free-for-all.

Industrial and Cleaning Uses

Industrial chemists use tripotassium orthophosphate to remove stubborn stains and clean machinery, boilers, and metal parts. This compound releases greasy deposits without leaving harmful residues, which makes it valuable in food-processing equipment as well. While it doesn’t pose huge health dangers under ordinary use, it’s still a chemical—you wouldn’t want to dump it in your local stream, and workers need good protective gear handling concentrated forms. In my time working around cleaning crews in industrial bakeries, I saw routines where everyone paid close attention to rinsing and avoiding spills, for both safety and environmental reasons. Every workplace benefits when folks know what’s in the materials they handle daily.

Points to Watch and Ways Forward

I’ve often found people surprised at how ingredients like tripotassium orthophosphate work their way from soil to plate to factory floor. As we rethink diets and environmental impact, paying attention to where and how these compounds show up keeps us better informed. Oversight matters, from food safety regulations to agricultural guidelines and waste management at factories. More research into long-term health impacts and runoff control would help shape smarter policies. One thing’s for sure: transparency in labeling, practical training in industrial settings, and encouraging home gardeners to avoid dumping leftovers down the drain can all play a big part going forward.

By rooting our choices in clear science and practical habits, tripotassium orthophosphate can keep serving its many roles without causing hidden trouble.Is Tripotassium Orthophosphate safe for consumption?

Looking Beyond the Label

Plenty of food products include unfamiliar chemical names on the back of the package. Tripotassium orthophosphate comes up a lot in cereals, canned soups, and occasional drinks. Eating snacks with long ingredient lists used to make me nervous—long words on the label often signaled trouble. But is this particular additive worth that worry?

Understanding Tripotassium Orthophosphate’s Role

Tripotassium orthophosphate works as an acidity regulator and emulsifying agent in processed foods. The food industry uses it to hold ingredients together and stabilize shelf life. In science class, phosphate compounds like this one were described as harmless building blocks for human life; our DNA and bones both need phosphates. Tripotassium orthophosphate is a salt derived from orthophosphoric acid and potassium, and the body relies on potassium to help keep heart and muscle function running smoothly.

What Scientific Evidence Shows

Digging into peer-reviewed literature, I found that food-grade tripotassium orthophosphate is considered safe by both the US Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). Regulators review food additives by looking at toxicological studies, animal testing, and any available long-term data. So far, no solid evidence links typical amounts in food to any direct harm in healthy adults.

Excess phosphate, according to the National Institutes of Health, only tends to pose a problem for people with advanced kidney disease. Healthy kidneys regulate extra phosphate, but impaired kidneys can't clear it, risking mineral imbalances or cardiovascular issues. The risk comes from consuming large quantities of phosphate additives over an extended period, not from the tiny amounts in single servings found in most foods.

Diet and Perspective

Most people in the US eat more than enough phosphates because processed foods fill grocery store shelves and our daily diets. In moderation, potassium phosphates, including tripotassium orthophosphate, won’t generally send phosphate intake through the roof. Nutritionists point out that focusing on whole foods—fruits, vegetables, and lean protein—naturally helps avoid any overexposure to additives like this one.

While the numbers show general safety, there’s a cultural piece to this story. Food manufacturers often reach for additives to cut costs or extend shelf life, not necessarily to improve nutrition. I learned to read ingredient lists not just for what they contain, but also for what they say about how a product was made. Grocery choices drive the market. Showing demand for cleaner labels can encourage the food industry to cut back on complicated additives when simpler ingredients would do.

Looking for Solutions

Reducing reliance on additives starts at home and in community conversations. Learning basic cooking skills helps eliminate the need for packaged, processed meals high in preservatives and phosphates. Policy makers can work with nutritionists and scientists to keep reviewing the science as food trends and technology shift, updating guidelines so that new research gets reflected in what regulators consider safe.

Knowing what goes in our food gives everyone better control over health. Tripotassium orthophosphate, based on current evidence and its regulatory approval, looks safe within normal dietary amounts. Just like with salt and sugar, balance and variety in the diet offer the safest bet.

What are the chemical properties of Tripotassium Orthophosphate?

What Sets Tripotassium Orthophosphate Apart

Tripotassium orthophosphate—also known as potassium phosphate tribasic—shows up as a white, hygroscopic crystalline powder. Its chemical formula, K3PO4, sets the tone for its high alkalinity. Water brings out its true character, dissolving it quickly and producing a strongly basic solution. That basic property has real consequences, since potassium phosphate solutions can irritate the skin and eyes, and should never be taken lightly in the lab or in industrial settings.

Strong Alkalinity in Daily Practice

Mixing this compound into water creates a pH that can soar above 12. This puts it in line with some of the harsher household cleaning products. That’s no small matter if you work with surfaces or metals that corrode easily, like aluminum or zinc. Over time, this kind of strong base eats into those materials, causing pitting or even full-on breakdown. Folks working in water treatment or agriculture learn to respect the power packed into this crossroad of potassium and phosphate.

Reaction Potential and Real-World Use

Tripotassium orthophosphate doesn’t just stop at making things basic. This chemical interacts with calcium and magnesium, often pulling them out of solution by forming relatively insoluble salts. This reaction finds plenty of practical application. In dishwashing detergents, for instance, this precipitation helps soften water, making for a cleaner wash and less scale in pipes. That interaction—binding up minerals—meshes well with my own chemistry experience. More than once, I’ve seen what happens to glassware that’s not rinsed well after using strong bases like this one: the surface can get cloudy from mineral deposits locked up by the phosphate ions.

Stability and Environmental Factors

Potassium phosphate tribasic keeps its head in dry, well-sealed containers. Left open to humidity, it draws in moisture right out of the air, clumping up fast. This tendency means storage becomes crucial—not just for convenience, but for safety. Moist clumps can make accurate measurement impossible and spill into the air easily, raising the risks of irritation.

The phosphate part of the molecule opens a different conversation. Phosphates feed algae when they wash into streams, lakes, or ponds. Blooms can follow, robbing oxygen from the water and wiping out fish. Agriculture and municipal cleaning crews have felt the pressure to keep runoff of these chemicals in check for good reason. My years working with water quality specialists taught me that even a few parts per million can tip a fragile balance, changing an entire ecosystem for the worse. Some jurisdictions now mandate alternatives that won’t fuel algal blooms.

Potential for Safer Handling and Alternatives

Proper protection goes far. Gloves, goggles, and solid protocols help people avoid chemical burns and respiratory irritation. For storage, airtight containers and a dry, ventilated environment hold moisture at bay. That aside, some sectors have shifted toward less aggressive bases or phosphate-free blends, especially where water discharge feeds into sensitive natural areas. These alternatives often require changes up and down the supply chain, but the long-term gains for water quality push the industry forward. As science pulls more data on the environmental footprints of products like tripotassium orthophosphate, decision-makers get the chance to weigh the benefits of chemistry against stewardship of the land and water that sustain us.

How should Tripotassium Orthophosphate be stored?

The Risks of Lax Chemical Storage

Big white sacks labeled "Tripotassium Orthophosphate" often blend into the clutter in storerooms and labs. This chemical isn’t especially flashy, but that can be part of the problem. Everyone assumes someone else knows how to handle it. I've seen labs where bags leak, sticky dust creeps across tables, and nobody quite remembers who opened the last container. Ignoring rules because you think a chemical looks harmless can set you up for a nasty accident—or at least, expensive cleanup and a headache.

Why Moisture and Air Matter

Tripotassium orthophosphate absorbs moisture from the air. Leave a lid loose or a bag untied, and soon you’ll find a gritty, clumping mess that’s much harder to measure. More importantly, moisture invites a chemical reaction with other substances. Even a hint of the wrong vapor, such as acids stored nearby, can change what you have in the tub. Storing this compound in a dry, tightly sealed container makes all the difference. Lined, dedicated cabinets—or bins with robust gaskets—keep humidity from turning your inventory into a giant salt lick. Getting this right saves money and worry.

Temperature and Light—Not Always Obvious Problems

It’s easy to forget your storeroom heats up through the afternoon. Direct sunlight or a hot water pipe along the wall cooks whatever’s on the top shelf. If tripotassium orthophosphate bakes or sits in freezing conditions, the particles can clump or break down. That makes handling unpredictable—the last thing anyone needs. Stash it out of sunlight and away from vents. Room temperature works well. Maybe an old fridge is empty and running; repurpose it as a chemical pantry, if you check it often and nobody mistakes it for a lunchbox.

Safety from Spills and Mix-ups

Here’s a story. In a small school lab, someone propped a leaky container over cheap plywood. Months passed, and corrosion crept across the shelf like a silent tide, finally collapsing onto bottles underneath. Cleaning up costs hours and some pride. If you set containers atop metal or untreated surfaces, that risk grows. I stick to plastic trays with a lip to catch loose granules—easy to swap out and rinse.

Why not all labels are equal

In big supply rooms or busy shared spaces, someone always forgets what’s inside a battered plastic jug. Permanent ink wears off. I once watched a senior tech mistake tripotassium orthophosphate for a detergent, then wondered for weeks why things foamed in the rinse tank. Label every container when it comes in. Write the full name, purchase date, and a big chunk of hazard info plainly on the outside. No one likes being the fool who dumped the wrong powder down a drain.

Solutions that Stick

At the end of the day, handling tripotassium orthophosphate safely takes a little patience. Record keeping, clear labeling, and regular spot checks cut surprises. Training fresh faces on your team helps everyone remember why those habits matter. Accident logs hold lessons worth sharing. Dry, dark, cool, and out of the way—that’s where this chemical belongs. Store it with intention, and you’ll never have to deal with a disaster that started as a simple oversight.

Is Tripotassium Orthophosphate approved for use in food products?

Understanding the Role in Food

Walk down a grocery aisle, and you might see tripotassium orthophosphate listed among the many long, complicated ingredients in processed foods. This compound often turns up in powdered drink mixes, processed cheeses, and breakfast cereals. Its main job is to buffer pH, keep food moist, and work as an emulsifier. Scientists have known for years that food needs the right balance to stay fresh, taste good, and remain safe to eat long after it leaves the factory.

Regulatory Status in the United States

The U.S. Food and Drug Administration (FDA) has given tripotassium orthophosphate a thumbs-up as a food additive. The FDA lists this phosphate salt on its registry of substances generally recognized as safe (GRAS). That means, after looking at the research, the agency trusts that using the ingredient in specific amounts won’t put people at risk. The Code of Federal Regulations (21 CFR 182.6285) includes clear guidance on its allowed uses.

International Perspective: European and Global View

Looking beyond the U.S., food safety agencies in the European Union and Canada allow use of tripotassium orthophosphate in food as well. The European Food Safety Authority has reviewed the compound and reaffirmed that it doesn’t pose a safety risk at the commonly used levels in foods. This widespread approval didn’t happen overnight. Phosphate salts have a long track record in the global food supply, and regulators keep an eye on new research and manufacturing practices.

Safety, Public Health, and Ongoing Debate

Safety agencies set strict limits for how much phosphate can go into processed food. That’s not just about tripotassium orthophosphate. The bigger issue centers on total phosphorus intake. Phosphates help make food taste better and last longer, but too much phosphorus may cause problems for people with kidney disease and those at risk of weak bones. The average American already eats far more phosphorus than nutrition labels suggest.

Cases of excess phosphorus coming from phosphate additives in manufactured food caught the attention of public health researchers over the last decade. The CDC keeps noting how important it is that people with kidney or heart problems talk to their dietitian or doctor if processed foods are a big part of their diet.

Solutions for Consumers and Industry

For food producers, the challenge is to keep the benefits — like better texture and increased shelf life — while also using the minimum effective dose. Phosphate content often sits in the fine print of ingredient labels, making it hard for the average shopper to track. Efforts to add more phosphorus values to nutrition facts panels could help, especially for those who need to monitor intake due to health reasons.

At home, real food wins the day. Cooking with fresh ingredients and checking labels helps limit exposure to phosphates. Some supermarkets and brands now highlight phosphate-free lines for shoppers on restricted diets. Group efforts matter here — scientists, regulators, and food makers all shape what ends up on shelves.

Moving Forward with Food Transparency

Tripotassium orthophosphate plays a useful part in modern food science, yet demands ongoing attention as dietary habits shift. Transparency in food labeling and a focus on fresh, wholesome meals at home can protect health while allowing space for genuine food innovation. Open conversations and trusted information fuel better choices, one well-read label at a time.

| Names | |

| Preferred IUPAC name | tripotassium phosphate |

| Other names |

Tripotassium phosphate Potassium phosphate tribasic Phosphoric acid, tripotassium salt Tripotassium monophosphate |

| Pronunciation | /traɪ-pəˈtæsiəm ɔːrˌθəˈfɒsfeɪt/ |

| Preferred IUPAC name | Tripotassium phosphate |

| Other names |

Tripotassium phosphate Potassium phosphate tribasic Phosphoric acid, tripotassium salt Tripotassium monophosphate |

| Pronunciation | /traɪ-pəˈtæsiəm ɔːrˌθəʊˈfɒsfeɪt/ |

| Identifiers | |

| CAS Number | 7778-53-2 |

| Beilstein Reference | 1722999 |

| ChEBI | CHEBI:33302 |

| ChEMBL | CHEMBL1201547 |

| ChemSpider | 15018 |

| DrugBank | DB14527 |

| ECHA InfoCard | 03b4f397-2c3f-4edc-959f-8ba62e9c5e2d |

| EC Number | 238-961-5 |

| Gmelin Reference | 52958 |

| KEGG | C14318 |

| MeSH | D019346 |

| PubChem CID | 103185 |

| RTECS number | TC6615500 |

| UNII | 8NZQ3PO35W |

| UN number | UN3262 |

| CAS Number | 7778-53-2 |

| Beilstein Reference | 13366 |

| ChEBI | CHEBI:33364 |

| ChEMBL | CHEMBL1201193 |

| ChemSpider | 9471 |

| DrugBank | DB14528 |

| ECHA InfoCard | 03b9e987-1c33-41a2-ab36-99bba92f9f5a |

| EC Number | 231-907-1 |

| Gmelin Reference | 67621 |

| KEGG | C01840 |

| MeSH | D019276 |

| PubChem CID | 24450 |

| RTECS number | TC6615500 |

| UNII | NTH09L3BQH |

| UN number | UN2468 |

| Properties | |

| Chemical formula | K3PO4 |

| Molar mass | 212.27 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 2.564 g/cm³ |

| Solubility in water | Soluble |

| log P | -2.6 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 12.4 |

| Basicity (pKb) | 12.32 |

| Magnetic susceptibility (χ) | Diamagnetic |

| Refractive index (nD) | 1.487 |

| Dipole moment | 0 D |

| Chemical formula | K3PO4 |

| Molar mass | 212.27 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 2.564 g/cm3 |

| Solubility in water | Very soluble |

| log P | -2.6 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 12.35 |

| Basicity (pKb) | 11.8 |

| Magnetic susceptibility (χ) | +71.0e-6 cm³/mol |

| Refractive index (nD) | 1.487 |

| Dipole moment | 0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 265.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1576 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3791 kJ/mol |

| Std molar entropy (S⦵298) | 269.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1656 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -4184 kJ/mol |

| Pharmacology | |

| ATC code | A09AX04 |

| ATC code | A12BA03 |

| Hazards | |

| Main hazards | Irritating to eyes, skin, and respiratory system. |

| GHS labelling | GHS07, Warning, H319, P264, P280, P305+P351+P338, P337+P313 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | Hazard statements: "Causes serious eye irritation. |

| Precautionary statements | IF IN EYES: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. If eye irritation persists: Get medical advice/attention. Wash hands thoroughly after handling. |

| NFPA 704 (fire diamond) | 1-0-0 |

| Autoignition temperature | > 480°C (896°F) |

| Lethal dose or concentration | LD50 Oral - rat - **4,250 mg/kg** |

| LD50 (median dose) | > 3,840 mg/kg (rat, oral) |

| NIOSH | TTQ |

| PEL (Permissible) | Not established |

| REL (Recommended) | 15 mg/m³ |

| Main hazards | Causes skin and serious eye irritation. |

| GHS labelling | GHS07, Warning, H315, H319, H335 |

| Pictograms | GHS05,GHS07 |

| Signal word | Warning |

| Hazard statements | Hazard statements: Causes serious eye irritation. |

| Precautionary statements | P264, P280, P305+P351+P338, P310 |

| NFPA 704 (fire diamond) | 2-0-1 |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD50 Oral - Rat - 5,700 mg/kg |

| LD50 (median dose) | TDLo oral rat 5,170 mg/kg |

| NIOSH | TTQ047 |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | 300 mg/m³ |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

Potassium dihydrogen phosphate Dipotassium hydrogen phosphate Monopotassium phosphate Sodium phosphate Ammonium phosphate Calcium phosphate Magnesium phosphate |

| Related compounds |

Monopotassium phosphate Dipotassium phosphate Sodium phosphate Potassium dihydrogen phosphate Tetrapotassium pyrophosphate |