Potassium Dihydrogen Phosphate: Beyond the Lab Bench

Historical Development

Potassium dihydrogen phosphate came into the chemical story during the late 19th century, riding the tide of mineral fertilizer discovery and demand. Scientists and farmers realized that plant growth depended on more than just watering seeds and hoping for the best. Phosphates entered the fertilizer mix steadily, but potassium dihydrogen phosphate made its mark thanks to its reliable solubility and low toxicity compared to older, harsher salts. Early chemical companies worked in dim, drafty labs, mixing mineral acids with phosphate rocks and potash. Over the decades, the process for producing this salt became tighter and cleaner, moving from labor-intensive glass beakers to automated reactors running round the clock.

Product Overview

Today, potassium dihydrogen phosphate turns up across dozens of industries. Anyone handling dry, white, crystalline powders in food packaging, agricultural blends, or even fire-extinguishing formulations has likely scooped or mixed this salt. It carries the chemical formula KH₂PO₄—simple, but behind every bag lies careful control of purity, trace metals, and pH. Stepping into any chemical storage room, you’ll see different bags with their product grade stamped clearly: food, reagent, fertilizer. Each grade answers a different set of rules from different regulators, each batch tracked and referenced by lot numbers that stretch back for months or years.

Physical & Chemical Properties

In its finished form, potassium dihydrogen phosphate appears as tiny white crystals or as powder with little odor and no hint of the caustic substances used upstream. It dissolves readily in water, giving a clear, neutral solution. The molecular weight comes in at 136.09 g/mol. Melting starts above 250°C, but nobody in normal industry settings pushes it that far. In dry air, it stays pretty stable—only under humid conditions does caking crop up. Labs record it as a salt with moderate hygroscopicity; anyone pouring large drums can feel it stick to gloves in summer. From a chemical perspective, KH₂PO₄ is a strong acid salt of phosphoric acid and potassium, swinging the pH of solutions into the mildly acidic side of things.

Technical Specifications & Labeling

Spec sheets list typical purity at 98-99.5%, with strict limits for heavy metals, insolubles, arsenic, and iron. Food-grade product stays below 10 ppm for lead and below 2 ppm for arsenic, since even tiny contamination in processing can build up in supply chains. Fertilizer grades skip some of these checks, but every bag still posts its phosphate (P₂O₅) and potassium (K₂O) content. Barcodes, batch numbers, and best-by dates keep track of each shipment, adding traceability should any issue with contamination or blending appear. Labeling rules in many countries now list both the chemical name and E number for food additives (E340).

Preparation Method

Production steps echo the era before digital sensors took over: react purified phosphoric acid with potassium carbonate or potassium hydroxide in heated vessels. Engineers watch for correct temperatures to avoid side reactions. Reaction tanks bubble and mix, sometimes for hours, until the salts settle out. Solids then dry in rotary kilns or vacuum evaporators, ground to spec, and packed. Workers stay alert to rates of addition—pouring acid too fast or at the wrong temperature leads to uneven quality. Modern facilities monitor impurities at different stages, keeping phosphate recoveries high and waste streams to a minimum where possible.

Chemical Reactions & Modifications

Chemists working with potassium dihydrogen phosphate enjoy its straightforward reactivity. In buffers, it teams up with disodium hydrogen phosphate to balance pH, making it invaluable for cell culture media and biochemical assays. Its structure allows for coordination with metal ions in specialty catalysts. Reaction with bases like potassium hydroxide generates dipotassium hydrogen phosphate, a common tweak done in both lab and industrial settings. When heated strongly, it can transform into metaphosphates, used in specialty glass and flame-retardant applications. More reactive chemists try phosphorylation reactions on organic molecules, relying on the dual acid-base character of KH₂PO₄.

Synonyms & Product Names

Depending on the catalog or the decade, potassium dihydrogen phosphate answers to many other names. References to monopotassium phosphate, MKP, and primary potassium phosphate all point back to the same chemical. In fertilizer trade, “MKP 0-52-34” describes the N-P-K content (zero nitrogen, 52% P₂O₅, 34% K₂O). Food and pharma packaging uses E340 (i) among other identifiers. Scientists tracking old journal articles sometimes run into older, less precise names, a reminder of the salt’s long record in both industry and academia.

Safety & Operational Standards

Handling potassium dihydrogen phosphate brings fewer health hazards than other salts in its class, but nobody should skip basics like gloves and dust masks. Long hours in dusty warehouses or in fertilizer loading stations can still send particles into airways, so good ventilation matters. Regulators such as OSHA and ECHA set occupational exposure limits to keep workers away from eye or skin irritation. Food safety authorities like EFSA and FDA set maximum daily intake values for phosphates, especially for manufacturers using large quantities in beverages or bakery products. Spills wipe up readily with water, though runoff might contribute to phosphate loading in waterways—an environmental issue needing strict containment. Training and audits ensure that both old hands and new operators keep exposure low.

Application Area

Potassium dihydrogen phosphate keeps cropping up in greenhouses, hydroponics, and crop fields. Gardeners and commercial growers appreciate its speed in dissolving and feeding roots with phosphorus and potassium. Bakers depend on it as a leavening agent and buffer; it stabilizes cheeses and dairy blends, helping prevent texture problems. Industrial water treatment plants rely on its mild acidity and ion-balance in their blends for corrosion control. Buffer solutions across drug development, diagnostic kits, and research labs nearly always start with a weighed portion of this salt. Even the fire safety sector sees regular use, as potassium phosphates form the core of many class ABC fire extinguishers, slowing combustion by coating surfaces in inert minerals.

Research & Development

Current research digs into micronutrient delivery, precision agriculture, and slow-release phosphate coatings. Every season, crop nutrition companies invest millions to see where potassium dihydrogen phosphate can fit in reducing fertilizer runoff and improving uptake. Biomedical labs experiment with phosphate-buffered systems to grow more delicate cells, often tweaking salt concentrations to support specific physiological processes. Battery and solar cell manufacturers investigate phosphate salts as novel electrolytes or flame-retardant additives. My own time in a chem-lab taught me that any new buffer formulation started with some grade of KH₂PO₄—the salt’s reliable pKa and low cost always win over fancy synthetic alternatives. Researchers keep one eye on maximizing plant yield and another on reducing environmental load.

Toxicity Research

Years of studies confirm that potassium dihydrogen phosphate presents little risk at ordinary exposure levels. Large overdose in animals sometimes brings muscle cramps or kidney stress, but these doses rarely approach common consumer use. Ecotoxicity tests flag the cascading effect of too much phosphate draining into rivers—algae blooms and oxygen crashes threaten local wildlife. International health agencies base daily intake limits on rodent studies, balancing essential nutrient needs with risks of hyperphosphatemia, particularly in people with kidney impairment. Industry monitoring now tracks effluent phosphate levels to reduce the chance for long-term accumulation in surface waters. Fact-based reviews keep regulators and manufacturers focused on real risks, not rumors.

Future Prospects

Looking ahead, potassium dihydrogen phosphate faces a crossroads shaped by global demand for sustainable agriculture and tighter food regulations. With mounting pressures on phosphorus reserves, companies pursue recycling methods for phosphorus recovery from waste streams—turning back the clock on a linear resource model. Efforts to develop slow-release versions and micronutrient-fortified formulas continue, chasing improved efficiency and lower environmental impact. Solar manufacturers search for better flame retardants, and battery researchers tap into its potential for novel electrolyte systems. Plant researchers and food scientists keep running experiments, hunting for new ways to thread this old chemical through modern challenges. The future may favor those who stick to facts, track impurities, and never lose sight of the basic principles that drove its discovery in the first place.

What is Potassium Dihydrogen Phosphate used for?

What is Potassium Dihydrogen Phosphate?

Potassium dihydrogen phosphate, also called monopotassium phosphate, shows up in more places than most people realize. Whether in a greenhouse, a bakery, or a research lab, this white, powdery compound keeps popping up for one simple reason: it packs two of the world’s most essential elements—potassium and phosphorus—into an easy-to-handle form.

Growing Healthier Plants

Anyone who digs in the dirt for a living or as a hobby probably recognizes this chemical on fertilizer labels. Plants crave potassium and phosphorus for strong roots and big blooms. In my own garden, mixing monopotassium phosphate with water and feeding it to tomatoes made a real difference in yield. On a larger scale, commercial farmers rely on it during the fruiting and flowering stages. Research supports its role; both potassium and phosphorus play a direct part in photosynthesis, energy transfer, and disease resistance.

Unlike some fertilizers that stick around in the soil and build up salt, this one dissolves fast and delivers nutrients right to the roots. It’s a favorite in hydroponics and intensive cultivation because the rapid uptake supports fast growth and reduces waste.

It Keeps Food Consistent—and Safe

Potassium dihydrogen phosphate makes regular appearances in commercial kitchens and factories. Bakers count on it as a leavening agent, where it reacts with sodium bicarbonate to help dough rise. In cheese-making, it acts as an emulsifier, keeping fats and proteins from separating. This keeps processed cheese smooth and sliceable, which every grilled cheese sandwich lover can appreciate.

Beyond texture, food safety matters. As a food additive, this compound adjusts pH, controlling how acidic or alkaline a food becomes. This makes it harder for bacteria and other microbes to grow, helping lengthen shelf life without resorting to harsher chemicals.

Cleaner Water Means Safer Science

Stepping outside the kitchen, laboratories everywhere mix potassium dihydrogen phosphate into so-called buffer solutions. I remember my first chemistry class, where these buffers kept pH steady during reactions. Many medical and environmental labs do the same. The reason? Even a small shift in acidity or alkalinity can mess up results. That’s a big deal when analyzing blood samples, testing water quality, or running DNA tests.

This same stabilizing ability finds its way into industrial water treatment. Factories rely on potassium dihydrogen phosphate to prevent scale inside boilers and pipes, keeping equipment running efficiently. People seldom see this direct effect, but it keeps tap water safe and manufacturing processes uninterrupted.

What About the Risks?

No conversation about chemical use should skip over safety. In food, regulatory bodies like the FDA approve potassium dihydrogen phosphate as safe, within certain limits. Still, the major concern pops up with overuse, especially in agriculture. Excess fertilizer can run off fields and end up in rivers and lakes, feeding algae blooms. These blooms damage aquatic life and threaten drinking water supplies. Responsible application remains key. Following soil test recommendations and keeping runoff in check offer practical solutions.

People often ask about health risks. In normal food amounts, the compound doesn’t raise red flags. People with medical conditions requiring a low-phosphorus or low-potassium diet should read labels closely, but those cases remain rare.

The Bigger Picture

Looking across farming, food, and science, potassium dihydrogen phosphate offers versatility and reliability. Whether helping tomatoes grow, whipping up a smoother sauce, or supporting lab experiments, this compound shows how a simple ingredient can have a big impact. Choosing responsible use—guided by sound science—keeps the benefits clear and risks managed.

Is Potassium Dihydrogen Phosphate safe for human consumption?

What Is Potassium Dihydrogen Phosphate?

Potassium dihydrogen phosphate shows up on nutrition labels with a name that sounds like it belongs in a chemistry class. In reality, this is a mineral salt. Many processed foods rely on it to regulate acidity and keep things fresh. I see it in some of my favorite sports drinks and instant puddings. Aside from keeping things shelf-stable, it offers a source of both potassium and phosphate—two elements the body uses every day.

The Safety Question

People often ask if this additive is actually safe. Regulatory groups in the United States, Canada, and Europe set clear rules for additives. The FDA lists potassium dihydrogen phosphate as “generally recognized as safe” when used as intended. The European Food Safety Authority reviewed studies on potential side effects, then determined typical dietary amounts don’t lead to harm. I like to dig into this whenever I see sensationalized headlines. What emerges is a story grounded in data—largely showing that most people eating balanced diets won’t face issues from small food additive amounts.

What Science Tells Us

Everyone’s body needs potassium to keep nerves firing and muscles moving. Phosphorus teams up with calcium for strong bones. With this additive, a small amount in packaged food just adds to the body’s supply. Diets that go way overboard with added phosphates—often due to a heavy focus on processed foods—can push blood phosphate too high. That mostly impacts people with chronic kidney disease, since their kidneys struggle to clear the extra phosphorus. A study published in the Journal of Renal Nutrition spells it out: patients with advanced kidney disease should steer clear of high-phosphate foods and additives.

Most healthy people process moderate phosphate intake without issue. Researchers who published guidelines for food safety found no evidence of toxicity from the amounts found in normal meals. Nutrition experts point out that common plant foods like beans and whole grains contain even more phosphorus per serving.

Where Trouble Can Creep In

Overconsumption remains possible. My own grocery trips show just how many foods in a single aisle use this additive. There’s a concern that a steady diet of highly processed foods leaves folks overloaded on sodium, phosphates, and low on fiber. That’s not a great combination for health in the long run. Instead of blaming one ingredient alone, I’ve seen better results when focusing on the big picture—reducing processed foods and bringing in more fruits, vegetables, and whole grains.

What Can People Do?

If you’re concerned about food additives, checking labels is a habit worth building. Potassium dihydrogen phosphate will turn up if you reach for many instant, packaged items. Choosing fresh foods more often makes that concern less of an issue. For people with kidney problems, it really helps to get personal nutrition advice from a registered dietitian, since monitoring phosphorus matters a lot more in those cases.

Regulators continue to monitor the science. If future studies uncover new risks, rules get reevaluated and updated. For most people, potassium dihydrogen phosphate in food serves its purpose without causing trouble. Health outcomes tend to hinge more on the whole pattern of eating rather than single ingredients in isolation.

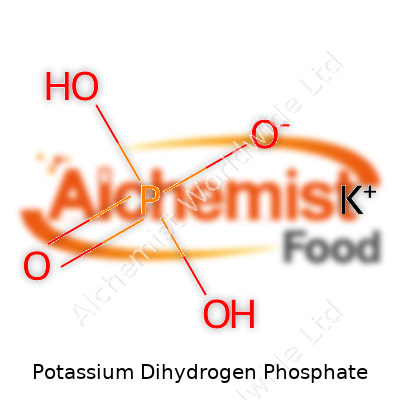

What is the chemical formula of Potassium Dihydrogen Phosphate?

Chemical Formula: KH2PO4

Look at a bag of fertilizer in almost any garden supply shop and the odds are high that the letters N, P, and K will stand out. Potassium dihydrogen phosphate, identified by the formula KH2PO4, gives gardeners one of the purest ways to boost those two key nutrients: phosphorus and potassium. I remember walking past stacked bags of this stuff in rural hardware stores, smelling dust and seeing hopeful growers planning bigger, healthier plants. It sits just as comfortably in a laboratory as it does in a hydroponic greenhouse.

The Building Blocks: Potassium and Phosphorus

Chemists see KH2PO4 and think of essential atoms—potassium (K), hydrogen (H), phosphorus (P), and oxygen (O). This combination creates a compound well-suited for both plant growth and controlled chemistry. Plant roots find potassium crucial for strong stems and efficient water uptake, while phosphorus drives root and flower development. Without enough phosphorus, maize leaves turn purple, wheat heads stay small, and tomatoes flower poorly.

The agriculture industry trusts potassium dihydrogen phosphate because it dissolves cleanly in water and releases nutrients without extra unwanted elements. A scientist or technician never has to worry about strange impurities unexpectedly affecting the result, so reliability stays high. That matters to farmers growing crops for food, to lab techs mixing solutions for experiments, and to those running water treatment facilities.

Application in Real Life

Potassium dihydrogen phosphate doesn’t only help on the farm. It acts as a buffering agent in food processing, helps adjust pH in chemical baths, and supports consistent nutrient delivery in hydroponic setups. Greenhouses looking to tune growth cycles rely on it. I’ve seen small producers cut costs by making their own nutrient mixtures with just KH2PO4 and calcium nitrate—no need for complex, expensive blends that add confusion and mystery.

Phosphate-based salts hit the headlines whenever fertilizer runoff makes its way into rivers and lakes, spiking algae and choking aquatic life. Even though potassium dihydrogen phosphate dissolves clean, overuse turns a helpful tool into a pollution risk. The Environmental Protection Agency reports that too much phosphorus in runoff feeds algae blooms, which can poison water and hit fishing communities hard. Responsible use, tested application rates, and runoff control turn a possible hazard back into an asset.

Balancing Use and Environmental Responsibility

The knowledge behind KH2PO4 reaches beyond chemistry and touches on sustainable agriculture. Precision farming—using just enough fertilizer, applied where plants can actually use it—reduces runoff and saves money. Farmers regularly work with agronomists to test soil and check plant needs before mixing nutrients. If big farms invested more in soil monitoring and drip irrigation, the right amount of potassium and phosphorus would reach crops and miss the creeks.

Potassium dihydrogen phosphate stands as an important compound that blends straightforward chemistry with a long-term agricultural impact. Used wisely, it helps feed the world and supports cleaner, smarter growing.

Can Potassium Dihydrogen Phosphate be used as a fertilizer?

Understanding Potassium Dihydrogen Phosphate

Potassium dihydrogen phosphate, known to some as monopotassium phosphate or MKP, shows up in bags at agricultural supply stores all over the world. It’s a simple compound—just potassium, hydrogen, and phosphate. At first glance, everything in this salt points to plant nutrition. Plants pull up potassium for root growth and disease resistance. They take in phosphate for strong buds and solid fruit. Both sit at the core of healthy crops, and that’s why MKP gets tested in farms and gardens from the Midwest to the tropics.

Why Potassium and Phosphate Matter

Through years walking farm fields and watching plants struggle or thrive, the role of the “big three” soil nutrients—nitrogen, phosphorus, and potassium—becomes clear. If one breaks down, so does the crop. Droughts and heavy rain wash away nitrogen, but phosphate and potassium often stay put, unless fields get pushed to extremes. Crops like wheat, tomatoes, and grapes start to yellow and curl without enough potassium. Phosphorus shortages mean stunted, late harvests.

MKP in the Field

Manufacturers make MKP in powder or crystalline form. Farmers dissolve it easily in water, then spray it through irrigation lines or directly to leaves as a “foliar feed.” The nutrients in MKP don’t hang around for long in soils that cling tightly to minerals. Its high solubility means roots get a quick shot of what they need, fast. This can boost flowering or fruit set at just the right time.

In hydroponic setups—think rows of lettuce growing in greenhouses without dirt—MKP forms a standard part of the nutrient mix. Plants pick up every bit, with nothing going to waste. Growers use it early in the growing season to establish strong root systems or late in the game to ripen fruits.

Balanced Approach is Critical

I’ve seen problems crop up when growers chase quick fixes or lean too hard on one nutrient. Pour on straight phosphate or potassium for too long and soil chemistry slips out of balance. Overuse brings clogged irrigation systems and salty ground, shrinking yields in the years that follow. In my own community garden, we test soil every year before adding phosphorus, since too much can stick around for decades, feeding no one and blocking other nutrients.

Organic farms sometimes hold back from products like MKP, opting for rock phosphate or composted manures instead. These release nutrients more slowly, which lines up with the pace of traditional farming but not always with the demands of commercial production. Big farms looking to speed up flowering in fruit orchards or vegetable fields often turn to MKP as a reliable, quick-acting source.

Pushing for Smarter Fertilizer Use

Farmers watch their costs and keep records of soil tests. Soil scientists work with them, encouraging targeted use of fertilizers, rather than broad application. MKP used exactly where and when a crop needs it reduces waste and runoff into streams. That approach cuts costs and helps protect rivers and drinking water. Not every crop or region calls for MKP, but for growers watching for clear signs of potassium or phosphorus shortages—and willing to keep tabs on soil health—it delivers results.

Responsibility means more than buying the right bag. It’s about knowing the field, tuning in to the signs from the plants, and keeping long-term soil health in sight. MKP won’t solve every issue in the field, but it serves as a tool many farmers rely on, season after season.

What are the storage requirements for Potassium Dihydrogen Phosphate?

Looking at the Essentials of Safe Handling

Potassium dihydrogen phosphate often shows up in agriculture, food production, and laboratory work. If anybody spends time around industrial and scientific storage rooms, they learn quickly that carelessness with chemical storage becomes expensive down the line. Shelves bottled with unlabeled substances or packed under leaky pipes always spell trouble. Even if potassium dihydrogen phosphate isn’t explosive or unpredictable like sodium, it still asks for respect during storage.

Moisture Management

Water in the air never seems like much of a threat until the powder in one bin turns rock-solid overnight. Potassium dihydrogen phosphate offers a good example: it pulls in water from humid air, clumping up and turning tricky to use. In every place I’ve visited—from grain warehouses in hot climates to university storerooms in rainy cities—the powders closer to open windows always suffer. Storing this chemical in sealed containers, away from drafts or leaks, keeps quality up and waste down.

Avoiding the Wrong Neighbors

Mixing chemicals without thinking reminds me of old science fair mistakes, where something harmless on its own causes a headache when mixed. Potassium dihydrogen phosphate doesn’t react the way strong acids or oxidizers do, but placing it next to strong alkalis or oxidizers leaves the door open for future problems. I’ve seen bins that accidentally held incompatible chemicals—one spill often means an entire shelf ends up in the hazardous waste bin. Smart facilities keep careful separation using distinct shelves or divisions, keeping the peace among both staff and substances.

Temperature and Light Considerations

Storage areas with wild temperature swings see products breaking down more quickly. Potassium dihydrogen phosphate wants a steady, cool, dry spot. Heat speeds up chemical changes and encourages more moisture in the air, eroding the clean, free-flowing powder that industries pay for. I remember one food factory fighting equipment clogs because of lumpy, overheated stock. Simple air conditioning or shaded spots usually solve the problem before it spreads.

Keeping the Workplace Safe

Chemicals don’t care who’s new or experienced—everyone makes mistakes if containers lose their labels or don't seal properly. One forgotten label leads to uncertainty, wasted product, and sometimes emergency calls. The best teams I worked with used color-coded labeling, frequent checks, and training refreshers to keep everyone on the same page. Safety sheets usually sit in a visible spot. Proper signage cuts confusion, and access to gloves, goggles, and other gear reminds folks it’s not baking powder they’re moving.

Simple Solutions for Better Storage

Investment in airtight containers quickly pays for itself by saving product and protecting health. Maintaining cool, dry conditions can be as simple as keeping windows shut during rain and using silica gel if budgets run tight. Assigning one person for weekly checks catches any signs of leaks, spills, or strange odors before they turn serious. Digital monitoring helps big operations, but attentive staff and a clean area matter just as much.

Responsibility in Chemical Management

The role of careful storage grows as operations scale up. Poor handling leads to expensive recalls and safety violations. Genuine knowledge comes from not just reading safety data sheets but sharing everyday lessons with new team members. In every setting—whether a small farm or a giant plant—paying attention now protects everyone’s work and well-being later.

| Names | |

| Preferred IUPAC name | Potassium dihydrogen phosphate |

| Other names |

Monopotassium phosphate MKP Potassium phosphate monobasic Potassium dihydrogen orthophosphate KDP |

| Pronunciation | /pəˌtæsiəm daɪˌhaɪdrədʒən fəˈsfeɪt/ |

| Preferred IUPAC name | Potassium dihydrogen phosphate |

| Other names |

Potassium phosphate monobasic Monopotassium phosphate MKP KH2PO4 Potassium dihydrogen orthophosphate |

| Pronunciation | /pəˈtæsiəm daɪhaɪˈdrɒdʒən fəˈsfeɪt/ |

| Identifiers | |

| CAS Number | 7778-77-0 |

| Beilstein Reference | 3567933 |

| ChEBI | CHEBI:62975 |

| ChEMBL | CHEMBL1201191 |

| ChemSpider | 7271 |

| DrugBank | DB09449 |

| ECHA InfoCard | 03e7b7c2-989c-4152-9341-99c8cf2b72ef |

| EC Number | E340 |

| Gmelin Reference | 3874 |

| KEGG | C14390 |

| MeSH | D010948 |

| PubChem CID | 516951 |

| RTECS number | TC6615500 |

| UNII | 19R8CF4V5U |

| UN number | UN9142 |

| CompTox Dashboard (EPA) | DTXSID5046977 |

| CAS Number | 7778-77-0 |

| Beilstein Reference | 357553 |

| ChEBI | CHEBI:62975 |

| ChEMBL | CHEMBL1201201 |

| ChemSpider | 50707 |

| DrugBank | DB09449 |

| ECHA InfoCard | 03a1a3b3-8d80-42c2-a0ae-8566d5f0ee0e |

| EC Number | 231-913-4 |

| Gmelin Reference | Gm.774 |

| KEGG | C00442 |

| MeSH | D017681 |

| PubChem CID | 516951 |

| RTECS number | TC6615500 |

| UNII | V74WT15865 |

| UN number | UN1477 |

| Properties | |

| Chemical formula | KH₂PO₄ |

| Molar mass | 136.09 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 2.338 g/cm³ |

| Solubility in water | 167 g/100 mL (20 °C) |

| log P | -2.0 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 12.4 (second), 7.2 (first) |

| Basicity (pKb) | 11.9 |

| Magnetic susceptibility (χ) | 'χ = -67.0·10⁻⁶ cm³/mol' |

| Refractive index (nD) | 1.509 |

| Dipole moment | 6.2 D |

| Chemical formula | KH2PO4 |

| Molar mass | 136.09 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 2.338 g/cm³ |

| Solubility in water | 33 g/100 mL (20 °C) |

| log P | -3.8 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 12.4 (second dissociation) |

| Basicity (pKb) | 11.9 |

| Magnetic susceptibility (χ) | -44.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.509 |

| Dipole moment | 6.23 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 115.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1477.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -2854 kJ/mol |

| Std molar entropy (S⦵298) | 110.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1476 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1567 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | A12BA01 |

| ATC code | B05XA13 |

| Hazards | |

| Main hazards | Not a hazardous substance or mixture. |

| GHS labelling | GHS07, GHS classification: Eye Irrit. 2A, H319 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Not a hazardous substance or mixture. |

| Precautionary statements | Wash hands thoroughly after handling. Do not eat, drink or smoke when using this product. IF SWALLOWED: Call a POISON CENTER or doctor/physician if you feel unwell. Rinse mouth. |

| NFPA 704 (fire diamond) | 0-0-0- |

| Lethal dose or concentration | LD50 (oral, rat): 17000 mg/kg |

| LD50 (median dose) | 2,820 mg/kg (rat, oral) |

| NIOSH | TTQ350000 |

| PEL (Permissible) | PEL (Permissible): Not established |

| REL (Recommended) | Oral: 17 mg/kg body weight |

| IDLH (Immediate danger) | No IDLH established. |

| Main hazards | May cause respiratory tract irritation. May cause eye irritation. May cause skin irritation. |

| GHS labelling | GHS labelling: Not classified as hazardous according to GHS. |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | May cause respiratory irritation. |

| Precautionary statements | Wash hands thoroughly after handling. If in eyes: Rinse cautiously with water for several minutes. Remove contact lenses, if present and easy to do. Continue rinsing. If eye irritation persists: Get medical advice/attention. |

| NFPA 704 (fire diamond) | 1-0-0 |

| Lethal dose or concentration | LD50 (oral, rat): 4,640 mg/kg |

| LD50 (median dose) | Oral-rat LD50: 4,640 mg/kg |

| NIOSH | TTQ350000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Potassium Dihydrogen Phosphate: Not established |

| REL (Recommended) | 13 mg/kg bw |

| Related compounds | |

| Related compounds |

Ammonium dihydrogen phosphate Sodium dihydrogen phosphate Monopotassium phosphate Disodium phosphate Dipotassium phosphate Phosphoric acid Potassium phosphate |

| Related compounds |

Monopotassium phosphate Dipotassium phosphate Potassium phosphate Monosodium phosphate Disodium phosphate Phosphoric acid |