Potassium Diformate: A Modern Feed Additive with Deep Roots

Historical Development

Potassium diformate crawled out of chemistry labs into the feed industry in the 1990s, long after scientists mastered formic acid’s chemistry. Food safety headlines and mounting pressure to cut antibiotics in animal feed nudged researchers toward organic acid salt solutions—potassium diformate being one of the earliest success stories. Experiments on pigs showed reduced gut pathogens, improved digestion, and better feed conversion. It didn’t happen overnight. Early technical hiccups with dosing, stability, and cost put the brakes on rapid growth. After field trials across Europe and Asia, this additive earned safety nods from global regulators, including the European Food Safety Authority. For feed millers, its arrival marked a turning point—livestock producers now had a practical alternative to old antibiotic crutches.

Product Overview

Potassium diformate falls into the family of organic acid salts. Sold in granulated or fine crystalline forms, it usually appears nearly white and carries a slightly acidic scent, thanks to the underlying formic acid. Unlike raw acids that can corrode steel and sting the skin, this salt offers similar preservative power without the same caustic punch. Its primary claim to fame is gut health. By acidifying animal diets, potassium diformate curbs harmful bacteria and supports beneficial microbes in swine and poultry feed. This helps reduce diarrhea, improve weight gain, and limit the use of antibiotics. Fewer pathogens in manure also mean fewer headaches for neighboring communities and environmental regulators.

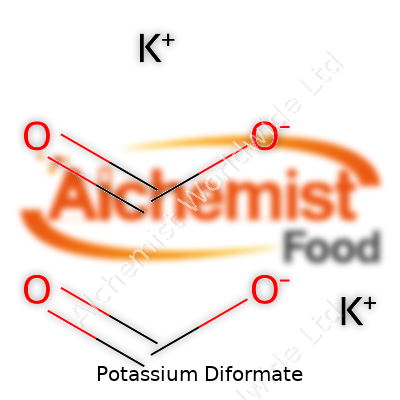

Physical & Chemical Properties

Crystalline potassium diformate carries the chemical formula KH(COOH)2. Its structure stems from potassium’s ability to bond with two formate ions, which hold two acidic hydrogen atoms. In practice, this gives the compound a molecular weight near 130.13 g/mol and leaves it highly soluble in water. In cold, damp feed rooms, it picks up moisture but doesn’t clump like sticky organic acids. Bulk density generally ranges from 800 to 900 kg/m3, which isn’t much different from typical mineral salts. Its melting point runs above 158°C, so it rides out most pelleting conditions just fine.

Technical Specifications & Labeling

Commercial potassium diformate products usually bring purity above 97%, leaving less than 3% as moisture and trace minerals. Labels highlight content of active formic acid, which usually hovers around 61%. Feed producers want that number to ensure they deliver the right dose for gut health without overshooting legal limits. Most countries enforce labeling standards that call for manufacturer details, batch codes, production dates, and shelf life—usually two years from the packed date if kept dry. Transport rules treat potassium diformate as non-hazardous, but workers still get advised to wear gloves and avoid raising dust clouds in the mixing room.

Preparation Method

On the chemical side, potassium diformate comes from direct neutralization. Manufacturers dissolve formic acid in water and add potassium hydroxide slowly, constantly mixing to keep temperatures in check. Excess acid adjusts the pH toward a mildly acidic range, then the solution gets filtered and dried using either spray or drum driers, which drive off water and yield fine white crystals. Automation helps control temperature swings, cut energy costs, and reduce operator exposure. Scrap from failed batches doesn’t go to waste; operators recycle it back into earlier steps whenever possible. Not many waste streams escape the plant.

Chemical Reactions & Modifications

With two carboxyl groups, potassium diformate reacts gently unless mixed with strong bases or oxidizers. It holds up well in pelleting and feed blending environments. Under very high heat, the formate ions can decarboxylate, giving off CO2. Exposure to stronger alkaline chemicals can shift the potassium towards more basic forms. Some R&D groups tried adding synergists such as medium-chain fatty acids or essential oils to the base product, hoping for added antimicrobial action. Certain chemical tweaks can boost solubility or allow the additive to resist clumping in especially humid regions.

Synonyms & Product Names

Potassium diformate doesn’t turn up under many different names, but the feed trade does toss around a few synonyms: potassium formate formic acid complex, K-diformate, and sometimes potassium methanoate-formic acid adduct. Registered trade names include Formi™, Addformate™, and ProMyr™. Companies compete based on granule size, flow properties, and country-specific regulatory approvals.

Safety & Operational Standards

Compared to bulk acids and antibiotics, potassium diformate rates much safer. Health and occupational exposure studies say the main risks involve dust and ingestion. Long-term inhalation of very fine dust may irritate airways, so production plants run dust extraction and workers don basic masks when opening big bags. European Food Safety Authority safety reports show no mutagenicity, reproductive toxicity, or organ damage at recommended doses for livestock or handlers. Regulatory bodies do set upper feed limits, usually around 12,000 mg/kg in complete feed for pigs. Disposal routines demand care to avoid untreated bulk in surface waters, which could shift pH in fragile ponds or streams.

Application Area

Swine feedyards use the lion’s share, targeting weaned piglets and sows. Nutritionists say younger pigs especially benefit—their guts lack strong acid and enzyme defenses. Some poultry barns add the product to chick starter diets, aiming to prevent salmonella and clostridia outbreaks. Certain shrimp and fish hatcheries experiment with low dosages in aquafeeds to limit pathogenic vibrio. Technical documentation describes compatibility with pelleting and most vitamin-mineral premixes. Its use as a direct food preservative rows upstream of mainstream practice, but fermented silages in parts of Europe do contain trace amounts to suppress spoilage. The additive rarely turns up in pet foods, partly due to limited research and customer sensibilities.

Research & Development

The early 2000s saw a surge in university-funded trials and industry-sponsored gut health research. Key studies linked potassium diformate to reduced E. coli and salmonella shedding, lower mortality, and better feed efficiency in pigs. Molecular biologists kept digging, tracking how the additive tweaks microbial communities and the thickness of intestinal walls. Recent work combines potassium diformate with enzymes or essential oils, chasing bigger performance jumps and healthier animals without antibiotics. A few projects use rapid NIR analysis to check final content in feeds, speeding up quality control loops. On the regulatory side, new demands for residue analysis and sustainability documentation push manufacturers toward less wasteful and traceable production chains.

Toxicity Research

Laboratory toxicologists and animal pharmacologists dove into the data, testing everything from single, sky-high acute doses to chronic exposure at realistic feed rates. The compound did not cause genetic mutations or trigger long-term organ problems at field doses. Some rare, high-dose gavage trials showed temporary kidney and liver bumps, but these fell far outside routine feeding scenarios. Studies in laying hens and broiler chicks chased impacts on egg quality, shell strength, and health—results showed no measurable harm. In people, accidental mouthfuls bring short-lived acid burn but no long-lasting effects. Wide safety margins led food regulators to sign off on use in feeds, provided that dosages stay inside published guides.

Future Prospects

Potassium diformate’s future ties to shifting rules and growing resistance to antibiotics on farms. As pressure mounts to ban or severely limit medicated feeds, livestock producers scramble for alternatives that won’t crater profits or wreck animal wellness. Potassium diformate will stay a mainstay in starter feeds while new combinations with botanical extracts, probiotics, or time-release capsules edge into the market. Regulatory bodies in Latin America, Africa, and South Asia keep working through feed approval pipelines, so access should broaden. If researchers solve the riddle of heat stability and synergistic blends at scale, the additive could break into dairy, aquaculture, and even specialty pet foods. Prices hinge tightly to global formic acid and potassium hydroxide supply chains—volatility in energy or chemical costs will shape its use by small- and medium-sized feed mills. With foodborne outbreaks still making headlines, wider use in silages and specialty processed foods could lift demand, as long as safety and label clarity follow through.

What is Potassium Diformate used for?

A Closer Look at Potassium Diformate in Animal Nutrition

Years spent on a farm teach a person how important it is to keep livestock healthy with the right feed solutions. Potassium diformate has turned up more and more in conversations among farmers and veterinarians, especially those raising pigs and poultry. It’s a white, water-soluble powder that stands out because it helps animals use their feed more efficiently and grow with fewer setbacks. Unlike some feed additives, it doesn’t leave that lingering chemical taste behind or change the way feed behaves in the trough.

Sitting down with an old friend who raises swine, he pointed out how feed costs make up the biggest share of his expenses. Any tool that stretches feed further or helps piglets reach market weight sooner means the difference between profit and struggle. Potassium diformate swings the odds in his favor by making the digestive process smoother. It lowers the pH inside the gut, keeping harmful bacteria like Salmonella and E. coli at bay.

Facing the Challenge of Antibiotic Resistance

Antibiotic resistance rides the headlines for good reason. Decades ago, antibiotics got blended into animal feeds to boost growth rates and stop disease from spreading. Over time, bacteria fought back, and the consequences now threaten both humans and animals. Policymakers in the European Union banned antibiotics for growth promotion, so feed manufacturers started looking for alternatives. Potassium diformate stepped in as a tool that doesn’t rely on antibiotics but still helps keep animals healthy.

Studies from organizations like the European Food Safety Authority show that pigs given diets with potassium diformate tend to weigh more by the end of finishing. Their digestive system performs better, and they shed fewer pathogens in their manure. By lowering stomach pH, this additive creates an unfriendly environment for germs, helping farmers cut down on sick days and medicine costs.

Practical Payoffs on the Farm

The farms that use potassium diformate often see improvements in feed conversion rates. Rather than shoveling more corn and soy into troughs, producers find that animals reach market weight with less waste. This doesn’t just boost profits; it cuts the strain on the environment. When animals use nutrients better, less nitrogen and phosphorus run off into groundwater, which means local rivers and streams stay cleaner.

From a food safety standpoint, fewer gut problems in pigs and birds translate to less risk of contaminated meat ending up on supermarket shelves. This doesn’t just protect the bottom line for a farmer; it guards the dinner table for everyone. Even workers handling feed notice less dust and stronger mixing, reducing health risks in the feed mill.

Moving Forward with Practical Solutions

Affordable feed additives with real benefits attract attention in tight markets. Potassium diformate fits that bill. It mixes easily with ordinary feed ingredients and scales up for large operations without special equipment. Instead of leaning on antibiotics, farms have another way to support animal growth and welfare. As more research pinpoints the best ways to use this additive, expect to see it show up in livestock barns across the country. The lesson seems simple: small changes in the feed bin can make a difference at the checkout counter, for farmers and grocery shoppers alike.

Is Potassium Diformate safe for animal feed?

Understanding Potassium Diformate

Potassium diformate often enters conversations about animal nutrition. Some know it as an additive blended into feed, mostly in swine farming. Its main role is to improve gut health and performance in pigs, especially after weaning. Researchers started investigating it as an alternative to antibiotics when regulators cracked down on antibiotic growth promoters. At the molecular level, this compound breaks down into formic acid and potassium when it hits the animal’s digestive tract. It manages gut pH and slows the growth of harmful bacteria, like salmonella and E. coli, in the intestines.

What Does the Research Tell Us?

Peer-reviewed studies back up many of the benefits claimed for potassium diformate. Swine given feed with this additive show better weight gain, healthier guts, and less diarrhea. European Food Safety Authority (EFSA) evaluated the evidence. They concluded this compound works well for piglets, sows, even broiler chickens. It helps performance without leaving toxic residues in meat. The authorities set maximum recommended levels, and the available evidence supports safety for animals as long as those levels stay respected.

Concerns That Get Raised

Anytime an additive gets used, farmers and consumers want to know about possible risks. One common question is whether potassium diformate creates hidden problems for animals or the food chain. Toxicologists have sifted through piles of feeding trials. They found no bad effects at normal inclusion rates. Some concern cropped up around what happens if animals get much more than the recommended amount, but studies show that at regular levels the compound leaves no harmful residues in tissue or milk. It breaks down fast and does not build up.

It’s also important to think about long-term effects. Feed additives sometimes surprise you after years of use. Up until now, potassium diformate hasn’t triggered any alarm bells in countries where it’s been approved and widely used, especially in Europe and parts of Asia. Regulators keep a close eye on any new evidence, requiring manufacturers to conduct safety tests for every proposed use.

Transparency for Farmers and Consumers

Trust rests on knowledge. Feed manufacturers often share detailed information about added ingredients, but labeling practices vary in different countries. Some markets want clear documentation about every additive, down to the milligram, while others rely on umbrella approvals from government agencies. For anyone concerned, asking for a detailed feed breakdown makes sense.

Many farmers lean toward additives with a solid body of research behind them. Potassium diformate fits that bill for pigs, supported by real-world experience as well as rigorous studies. It helps producers rely a little less on antibiotics, a big plus given the rising concern about resistance.

Looking Ahead: Smarter Use and Alternatives

Feeding regulations shift as science advances. Some are looking at organic acids and plant-based additives, hoping to get similar animal health benefits. Potassium diformate comes with a proven track record, but that doesn’t mean questions about its use should stop. Ongoing monitoring and transparent reporting will keep food and feed safe for people and animals.

In my experience visiting pig farms, additives that promise better health spark plenty of debate. The science around potassium diformate offers solid reasons for trust, as long as feed producers and farmers stick closely to recommended guidelines and regulators keep standards high.

What is the recommended dosage of Potassium Diformate?

Practical Dosage Insights

Potassium diformate grabbed a lot of attention as a feed additive, especially in pig farming. The European Food Safety Authority suggests 1.8% in complete feed for pigs, which works out to 18 grams per kilogram of feed. Most nutritionists I’ve talked to lean into slightly lower ranges, often using 0.6% up to 1.2% as a sweet spot, depending on the age and phase of the animal. Finishing pigs might thrive closer to the maximum allowance, but younger piglets benefit from the lower end. It’s not one-size-fits-all; weight, age, health status, and environmental pressures all play roles. Ignoring these means leaving performance on the table.

Why This Matters

Gut health in livestock isn’t just a trending phrase. In pigs, sour stomachs slow growth and cost real money. Potassium diformate works by making the gut less friendly to pathogenic bacteria, so the pigs digest better. In my own work with farmers, those stubborn post-weaning setbacks finally faded when diformate came into the mix. Still, as tempting as it is to pile on more, double-checking the dose keeps things from tipping from benefit to trouble. Too much creates palatability issues, with pigs backing off their feed. Overdosing wastes time and money and sometimes throws mineral balances out of whack.

Hard Data and Outcomes

A large field trial in Germany used Potassium diformate at 1.2%, leading to 5% better weight gain and dropping the need for therapeutic antibiotics by more than half. The data showed lower counts of E. coli in the animals’ guts. Those results didn’t magically pop up at higher or lower dosages. In farms I visit, the best gains always spring up in herds where they stick to tested ranges and actually monitor feed mixing consistently.

Regulation and Safety

The European Union caps Potassium diformate use at 18 grams per kilogram of complete feed to keep both animals and people safe. Sticking within these boundaries proves essential, not optional, for farm compliance and downstream food safety. In feed mills I’ve visited, lab staff check levels with the same regularity as checking for mold or salmonella. The key comes down to habit and knowing that feeding above the line risks both animal health and legal hassle.

Mistakes Happen, Solutions Exist

Even seasoned producers slip when they trust pre-mixes without reviewing inclusion rates. Problems with dehydration or unsteady feed intake usually flag overdose before it snowballs. Quality control teams should calibrate mixers often, double-check finished feed, and keep ingredient lots labeled. If in doubt, reach back to the supplier for fresh specs.

Practical Takeaways

The right dose isn’t just a number on a bag; it’s the payoff between healthier, faster-growing animals and wasted investment. Potassium diformate only works if it’s used smartly and consistently watched—there’s no shortcut. Like Grandma said with salt, 'Enough is good, but more won’t help.' Trust the evidence, stick to the range, and monitor results. The extra few minutes can make the difference between mediocrity and something impressive in the barn.

Does Potassium Diformate improve feed efficiency?

Looking at Feed Additives and Farm Realities

Raising animals brings a lot of tough decisions, especially when it comes to getting the most out of every pound of feed. Store shelves and trade shows show off hundreds of solutions, but most folks just want straight talk and real-world results. Potassium diformate gets plenty of attention among feed additives, and there are some good reasons for that. Some swine and poultry producers swear by it not only for growth but also for managing gut health.

Why People Use Potassium Diformate

Potassium diformate hit my radar about a decade ago while walking feedlots in the Midwest. Everyone wanted a replacement for antibiotic growth promoters because demand grew for more “natural” meat. Trials out of Denmark and Germany started reporting better weight gains, improved feed conversion, and even fewer digestive problems after switching to potassium diformate. Reports say it works as an acidifier, which can make the gut less welcoming to harmful bacteria and help animals better digest nutrients.

Researchers—like those from the European Food Safety Authority—confirm that potassium diformate often leads to better daily weight gain and a reduction in feed-to-gain ratios. That means animals need less feed to gain the same amount of weight. More efficient feed use cuts costs and reduces the overall environmental impact of livestock operations. For someone running animals at scale, that translates to real savings and steadier results.

The Science and the Skepticism

Not every trial finds the same bump in performance. Some herds or flocks see clear benefits, while others show little change. Factors like age, health status, feed composition, and farm management can shift the outcome. Big farms running consistent rations might see more predictable results. Small operations mixing batches on the fly may notice less difference.

Potassium diformate seems to lower stomach pH, helping piglets in particular make use of protein and minerals in feed. Fewer gut upsets mean more time growing instead of fighting off scours. Still, I’ve talked with farmers who saw less impact, usually where feed hygiene already scored well or where herds faced other health challenges. There’s no silver bullet for feed efficiency that suits every situation.

Economic and Environmental Angles

On good days, better feed efficiency reduces how much grain, soy, and energy goes into every kilo of pork or chicken. Farmers trim feed bills and feel less pressure from fluctuating corn prices. At the same time, more efficient digestion leads to less manure output and helps keep ammonia and phosphorus runoff in check.

Feed companies charge a premium for potassium diformate, though, so savings only show up if the improved conversion covers the extra cost. Producers juggling thin margins need clear cost-benefit numbers before making the switch.

What Might Help More Producers

Based on my own experience, consistent results depend on careful feed formulation and solid farm hygiene right alongside any additive. Using potassium diformate as part of a broader strategy—regular feed analysis, good water quality, and a tight vaccination plan—gives it the best shot at delivering the gains researchers describe.

If more open-access data compared feed efficiency gains across operations of differing sizes, farmers would trust the numbers more. Independent trials in different climates and with various feed blends could answer a lot of practical questions.

For now, potassium diformate deserves a spot on the short list of proven feed additives—especially for pig production—when the conditions fit. Watching costs and knowing your herd’s health remain just as important as choosing the next big additive.

Are there any side effects of using Potassium Diformate?

Understanding Potassium Diformate

Potassium diformate often shows up in the livestock industry. Farmers add it to pig feed, hoping to boost growth rates and keep gut health on track. European regulators have given it the green light for pigs, seeing benefits in terms of digestibility and performance. It's even recognized as one of the few organic acid salts that has undergone rigorous evaluation for feed use. But, just like anything added to food or feed, side effects can’t be ignored.

Side Effects for Animals in Feed

Over the years, researchers tracked pigs eating feed with potassium diformate. Most studies point out that normal doses don’t bring big issues. Feed conversion improves, fewer stomach troubles show up, and overall health tends to tick upward. In my own experience helping small family farms decide on feed additives, farmers noticed firmer manure with fewer strong odors—always a plus for anyone walking a pig barn. Still, no additive is risk-free.

Run the numbers too high, and things can turn sour. Potassium diformate works by lowering feed pH. So, add too much and the stomach becomes very acidic. Pigs, especially younger ones, might get mouth ulcers or mild gut irritation. Some researchers in Germany noted that at double the recommended dose, signs of stomach lining damage started to pop up. These are not the kind of problems a producer wants, as gut pain leads to less feed intake and slower growth. Sticking to recommended rates makes sense based on the field results.

Meat Safety and Environmental Impact

Consumers rightly ask: does potassium diformate in livestock feed end up in the meat on the dinner plate? Through peer-reviewed studies and food safety checks, potassium diformate breaks down quickly in the animal’s body, leaving little residue. The European Food Safety Authority found that animals metabolize and excrete it fast, without building up dangerous levels. That’s a big reason behind its approval for use in Europe.

What about runoff and the wider environment? Manure from animals fed potassium diformate doesn’t carry the same pollution punch as some other feed additives. Potassium itself gets picked up by crops out in the field after manure spreading. No clear sign points to lasting soil or water problems when farms use it within the legal rules.

Human Safety and Worker Health

Potassium diformate doesn’t appear in human supplements or foods. Still, folks who work with the powder during feed production should keep dust at bay. Breathing in additives in a mill or mixing plant raises the risk of lung irritation, much like with many mineral-based ingredients. Wearing a dust mask sounds simple but goes a long way, as I learned shadowing feed mill crews. Eye contact with the powder might also cause redness or watering. Simple gloves and goggles do the trick for safety.

What Needs Attention Going Forward

Potassium diformate doesn’t deserve a storm of worry, but even good tools need oversight. Regular training for farmworkers and mill operators goes a long way. Feed manufacturers benefit from basic safety sheets in the local language. Regulators should stay on alert, watching for new science about feed additives.

In all, potassium diformate can make a difference in modern farming. Taking small, clear steps to use it properly protects people, animals, and the broader environment.

| Names | |

| Preferred IUPAC name | Potassium methanedioate |

| Other names |

Potassium formate diformate Formic acid potassium salt (2:1) KDF |

| Pronunciation | /pəˈtæsiəm daɪˈfɔːr.meɪt/ |

| Preferred IUPAC name | Potassium methanedioate |

| Other names |

Potassium formate diformate Dipotassium diformate E 236 Diformic acid, dipotassium salt |

| Pronunciation | /pəˈtæsiəm daɪˈfɔːrmeɪt/ |

| Identifiers | |

| CAS Number | 20642-05-1 |

| Beilstein Reference | 1760943 |

| ChEBI | CHEBI:85077 |

| ChEMBL | CHEMBL1201144 |

| ChemSpider | 84116 |

| DrugBank | DB11453 |

| ECHA InfoCard | 100.104.573 |

| EC Number | 236-242-1 |

| Gmelin Reference | 23405 |

| KEGG | C18694 |

| MeSH | D000071246 |

| PubChem CID | 23666370 |

| RTECS number | VO5950000 |

| UNII | 6L6O2HM260 |

| UN number | UN3438 |

| CAS Number | 20642-05-1 |

| Beilstein Reference | 1721486 |

| ChEBI | CHEBI:87773 |

| ChEMBL | CHEMBL1200308 |

| ChemSpider | 144422 |

| DrugBank | DB11102 |

| ECHA InfoCard | 100.243.329 |

| EC Number | '246-921-0' |

| Gmelin Reference | 78776 |

| KEGG | C14351 |

| MeSH | D09.050.881.728 |

| PubChem CID | 83756 |

| RTECS number | UX8130000 |

| UNII | 6K51WEE698 |

| UN number | UN 2819 |

| CompTox Dashboard (EPA) | DTXSID9086524 |

| Properties | |

| Chemical formula | KHCO2 |

| Molar mass | 138.13 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 2.00 g/cm³ |

| Solubility in water | 700 g/L (20 °C) |

| log P | -4.6 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 3.3 |

| Basicity (pKb) | pKb: 3.92 |

| Magnetic susceptibility (χ) | -56.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.41 |

| Dipole moment | 2.55 D |

| Chemical formula | KHCO₂ |

| Molar mass | 130.13 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 2.0 g/cm³ |

| Solubility in water | soluble |

| log P | -2.7 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 3.1 |

| Basicity (pKb) | 8.2 |

| Magnetic susceptibility (χ) | -42.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.41 |

| Dipole moment | 1.72 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 130.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -756.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -802 kJ/mol |

| Std molar entropy (S⦵298) | 139.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -817.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -802 kJ/mol |

| Pharmacology | |

| ATC code | QA56AA30 |

| ATC code | B3AX50 |

| Hazards | |

| Main hazards | Harmful if swallowed. Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | GHS07, Warning, H319, P264, P280, P305+P351+P338, P337+P313 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | Precautionary statements: P264, P270, P273, P301+P312, P330 |

| NFPA 704 (fire diamond) | 2-0-0 |

| Lethal dose or concentration | LD50 (oral, rat): 3,400 mg/kg |

| LD50 (median dose) | LD50 (median dose): 3,400 mg/kg (rat, oral) |

| PEL (Permissible) | Not Established |

| REL (Recommended) | 6,000 mg/kg complete feed |

| IDLH (Immediate danger) | Not established |

| Main hazards | May cause respiratory irritation. Causes serious eye irritation. Causes skin irritation. |

| GHS labelling | GHS07, GHS08 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | Precautionary statements: P264, P270, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | 1-0-0 |

| Lethal dose or concentration | LD₅₀ Oral - Rat: 3,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): 1650 mg/kg (rat, oral) |

| NIOSH | GN1400000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Potassium Diformate: Not established |

| REL (Recommended) | 3,000 mg/kg |

| IDLH (Immediate danger) | Not established |

| Related compounds | |

| Related compounds |

Formic acid Potassium formate Sodium diformate Calcium formate |

| Related compounds |

Formic acid Potassium formate Sodium diformate |