Magnesium Sulfate Monohydrate: Navigating Past, Present, and Future

Historical Development

Magnesium sulfate’s journey stretches back centuries. Early healers used Epsom salts, discovered from Epsom springs in England, in medicine and agriculture. Over time, companies purified these natural deposits, learned the mineral’s structure, and isolated different hydrates, including the less common monohydrate. Historical texts describe its roll as a laxative, but soon, manufacturers started supplying it in technical grades for tanning, dyeing, and soil treatment. Shifts in chemical processing, especially during the Industrial Revolution, pushed chemists to look for easier ways to produce and standardize magnesium sulfate salts. Even today, discovery through observation, practicality, and scientific method shape how the world approaches this compound.

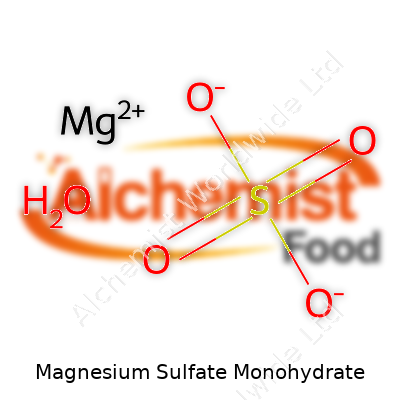

Product Overview

Magnesium sulfate monohydrate sits in that interesting spot between widely known and quietly crucial. Most people hear about the heptahydrate in Epsom salts yet don’t realize this monohydrate packs a punch in industry and agriculture. Frequently appearing as a white powder or crystalline solid, it supplies magnesium, a mineral humans, animals, and plants depend on for more than just a passing moment. Product packaging often describes its formula as MgSO4·H2O, but its applications range far past chemical equations.

Physical & Chemical Properties

Magnesium sulfate monohydrate, with a molecular weight of 138.38 g/mol, easily dissolves in water, less so in alcohol. Its density of about 2.66 g/cm³ and melting point near 150°C turn it into a strong choice for controlled-release fertilizers and technical reagents. Water binds directly into its crystal structure, making it less prone to caking compared to the heptahydrate. It tastes bitter — not a surprise — and the saturated solution’s moderate pH gives it flexibility in blending with common agronomic and chemical recipes. Its chemical stability in air allows for transport without excess care, easing logistical headaches, especially in bulk handling.

Technical Specifications & Labeling

Producers pay close attention to purity, clean packaging, and trace contaminant limits. Labs regularly assay for magnesium content, sulfate levels, and heavy metals, following standards from organizations like the European Pharmacopoeia and the US Pharmacopeia if the product targets pharmaceuticals or food. Labels on sacks or drums spell out not just weight but shelf life, storage temperature, and safety warnings. In agriculture and industry, smaller print often spells out batch numbers to ensure traceability back to individual production runs, a critical step if quality or supply chain questions come up.

Preparation Method

On an industrial scale, factories blend magnesium oxide or carbonate with sulfuric acid in stirred reactors, converting raw minerals into dissolved magnesium sulfate. The solution gets filtered, the solvent is carefully evaporated under controlled conditions, and cooling encourages the specific crystallization of the monohydrate. Skimping on evaporation or letting impurities sneak in spoils yield and product quality, so manufacturers often invest in vacuum conditions and temperature monitoring. Old practices depended on seasonal harvests from natural mineral springs. Modern plants deliver year-round supply without upsets from drought, rainfall, or fluctuating mine output.

Chemical Reactions & Modifications

Magnesium sulfate forms the backbone for several classic wet chemistry tests but plays a bigger role as a starting material for value-added composites. Acid modifies it further into other hydrates or basic sulfates needed for specialty applications. Thanks to its reactivity with phosphates and carbonates, it fits as a feedstock for specialty fertilizer blends. Reacting it with sodium hydroxide can produce magnesium hydroxide, important in flame retardants and wastewater treatment. Simple dehydration converts it to higher hydrates like the heptahydrate or, at high temperatures, to the anhydrous salt. Each tweak shifts its solubility, handling, or suitability for a new field, giving industrial chemists a challenge in process optimization.

Synonyms & Product Names

Folks in the industry switch between names: sulfuric acid, magnesium salt, monohydrate; magnesium sulfate hydronium; kieserite, though this commonly aligns with the natural mineral form. Labels in Asia sometimes print it as “light kieserite,” while distributors in Europe stick to “magnesium sulfate monohydrate (MgSO4·H2O).” CAS numbers, 14168-73-1 for the monohydrate, keep confusion to a minimum during international trade. Agricultural suppliers shorthand it to “Mg S Monohydrate,” highlighting its magnesium supply function.

Safety & Operational Standards

Magnesium sulfate monohydrate holds a relatively low risk profile, which means handling it rarely sets off alarms for acute toxicity. Touching the skin usually causes only mild irritation. Dust in the air brings risks of nose and throat itching, especially in closed spaces. Most plants require masks and gloves by default, because airborne powder can worsen asthma. Workers clean spills with water, avoiding mixing it with strong acids or bases, as exothermic reactions can splatter the powder. National safety agencies, like OSHA and ECHA, advise training staff to handle bulk chemicals safely, keep product away from sources of fire, and never store incompatible chemicals side by side.

Application Area

Magnesium sulfate monohydrate travels far beyond the lab bench. In agriculture, it feeds soil magnesium and sulfur demand in alkaline and neutral earth. Crops like potatoes, tomatoes, and citrus gulp it down, especially where sandy soils leach nutrients quickly. The food industry sometimes calls on it as a magnesium supplement in mineral waters and fortified cereals. Technical grade enters paper pulping, textile dyeing, and flotation agents used in mining. Specialty cement and fireproofing materials take advantage of its low reactivity and rapid solubility. A few companies use it for de-icing airport runways, a nod to its non-toxic, plant-friendly makeup compared to traditional chloride-based salts.

Research & Development

Universities and corporate labs run trials exploring how magnesium sulfate monohydrate supports plant uptake, especially when soils face stress from over-farming or climate shifts. Chemists tinker with granule shapes and coating technologies, looking to slow-release patterns or boost stability in combined NPK blends. Papers explore turning magnesium sulfate into new battery electrolytes or as an additive for more sustainable concrete. Some studies weigh its potential to help remediate salty, degraded soils in drought-hit regions, eyeing food security concerns. In medicine, researchers keep examining ways to tweak dosage forms and drug delivery to take better advantage of magnesium’s biological effects without running afoul of side effects.

Toxicity Research

Overall, magnesium sulfate ranks as safe at moderate levels, but misuse and overexposure invite health hazards. Animal and human studies hammer home the point: excessive ingestion may cause gastrointestinal upset, electrolyte imbalances, and at high exposures, cardiac risks. Fertilizer guidelines flag limits to avoid runoff into waterways, where excessive magnesium and sulfate can upset aquatic life and drinking water safety. Toxicologists highlight that magnesium sulfate monohydrate lacks serious carcinogenic or mutagenic effects, yet recommend layer-upon-layer of proper labeling to keep users informed and prevent accidental overuse.

Future Prospects

Demand for magnesium sulfate monohydrate isn’t slowing. Food supply and agricultural resilience call for more magnesium-rich inputs, and as the world tries to increase crop yields, the compound’s profile keeps rising. Battery innovators see potential by exploring it as part of sustainable electrolyte chemistry. Cement and construction fields ask for greener, safer additives, especially as governments set tighter emissions standards. Research circles buzz about new crystal engineering approaches to refine how the monohydrate gets delivered, with a goal to cut losses along supply chains. Wastewater specialists watch for ways to use magnesium sulfate to mop up phosphates, helping close nutrient loops and lower environmental footprints around the world. As climate and industrial needs shift, magnesium sulfate monohydrate finds itself in positions nobody could have predicted decades ago.

What is Magnesium Sulfate Monohydrate used for?

From Fields to Factories: A Pillar in Agriculture

Magnesium sulfate monohydrate isn’t a household name, but for anyone with ties to farming, the connection runs deep. Crops pull nutrients from soil each season, robbing dirt of the stuff that makes food possible. Magnesium stands out among essential plant nutrients—it helps plants turn sunlight into food. This isn’t theory. Many agronomists point to magnesium deficiency as a real hurdle for farmers growing tomatoes, potatoes, soybeans, and leafy greens.

Years ago, I watched an agronomist measure out magnesium sulfate for a field showing yellowing leaves and stunted growth. By the following month, the improvements in leaf color gave everyone reason to breathe easier. Replenishing soil with the right balance of magnesium and sulfur brought the crops back, a simple but powerful fix. Magnesium sulfate monohydrate makes this process reliable and affordable, so farmers can raise healthy food with fewer headaches.

Water, Wellness, and Industry

Palm calluses, sweaty foreheads, and sore muscles—all familiar after digging in the vegetable patch or a long workday. Magnesium sulfate plays another role in Epsom salt baths, soothing my own aches after weekends bent over garden beds. The science lines up: Epsom salts, often made with magnesium sulfate monohydrate, relax muscles, ease minor joint pain, and help with recovery for athletes and outdoor workers.

Healthcare taps into its benefits in other ways. Doctors reach for intravenous magnesium sulfate in hospitals to handle pre-eclampsia during pregnancy and certain irregular heartbeats. This is no folk remedy. Research from medical journals ties magnesium supplementation to lower occurrences of cramping and better nerve function. Hospitals trust this compound because it’s easy to dose and proven effective.

Cleaner Water and Stronger Industry

Beyond farms and medicine cabinets, magnesium sulfate monohydrate stays essential in industry. It cleans up wastewater from factories. It does this by binding to unwanted heavy metals—like lead and arsenic—pulling toxins from water so rivers and streams stay healthy. Most folks don’t see this work, but cleaner water means healthier communities and wildlife downstream.

On factory floors, magnesium sulfate monohydrate steps into the ring as a drying agent in chemical production. Paint factories, paper mills, and textile businesses count on its reliability to keep machinery running and products coming out right. These details might slip under the radar, but without these chemical processes firing on all cylinders, shelves back home would start to go empty.

Value and Responsibility

Quality matters at every step, whether it’s for a farm co-op sourcing fertilizers or a city planning for safe water. Impurities or mix-ups in the supply chain can mean lower yields, medical risks, or environmental damage. Regulators and producers lean hard on safety guidelines to keep standards high, and families rely on these protections for food, health, and security.

Magnesium sulfate monohydrate has a big job—feeding crops, helping people heal, clearing water, steering industries. The real challenge is keeping these uses clean, sustainable, and safe. Stricter quality controls, honest labeling, and fair access for every community create a safer path forward. Investing in soil health, transparent sourcing, and better environmental practices turns an everyday compound into something we all depend on—whether we know its name or not.

How should Magnesium Sulfate Monohydrate be stored?

Handling Matters: Why Proper Storage Counts

Every facility that works with chemicals feels a real difference between careless and careful storage. Magnesium sulfate monohydrate plays roles in agriculture, manufacturing, and healthcare. Manufacturers package it with a purpose: keep it usable, safe, and effective. Shoving it onto any old shelf risks product quality and workplace safety.

Moisture: Magnesium Sulfate’s Biggest Enemy

A humid corner in a warehouse ruins more than paperwork. Magnesium sulfate monohydrate absorbs water from air pretty greedily. Pulling open a bag in a muggy storeroom often leads to lumps or caking—bad news for mixing, measuring, or dissolving later. In my years around labs and plant storerooms, plenty of projects stalled just because the salt “went soft.” Sack up your supply in a dry spot. Run a dehumidifier in summer if you have to.

Tests by the US National Library of Medicine show magnesium sulfate monohydrate starts changing once humidity climbs past 60%. Keep it dry, and the material flows smoothly every time it leaves the bin. Humidity control isn’t optional—without it, it’s just a matter of weeks before whole bags solidify like a rock.

Cool, Not Cold: The Temperature Sweet Spot

Storing chemicals doesn’t always mean dragging in a refrigeration unit. Magnesium sulfate holds up fine at typical room temperatures. Extreme heat nudges it toward dehydration, and freezing can make the packaging brittle. I’ve noticed facilities get best results between 15°C and 25°C (59–77 °F). This range keeps most salts stable, and it’s easy for most storerooms to hit it with basic climate control.

Clean, Sealed Containers Mean Fewer Headaches

Factory packaging usually shows the right way to handle chemicals: thick plastic bags, usually with a label warning to reseal tightly. Torn packaging—forgotten after a busy week—leads to spoiled product. If a bag opens, transfer what you haven’t used to a clean, airtight container. Heavy-duty plastic bins work well, as long as the lid snaps tight. Chemical-grade storage buckets with gasket seals keep out both moisture and pests.

Don’t store magnesium sulfate near acids or strong oxidizers. These mix badly, making accidents more likely. I’ve seen cartons stashed next to bleach—big mistake. Dedicating one section of a storeroom shelf to mineral salts like magnesium sulfate keeps confusion low and makes safety training straightforward.

Trust What You See: Simple Daily Checks

People working in storerooms—especially those new to chemical storage—sometimes overlook what their own eyes and hands tell them. Feel for lumps, check bags for condensation or tears, and pull out any stock that looks “off.” Most problems show up fast. Staff who run spot checks once a day catch moldy or wet packaging before it ruins a whole pallet.

Making Storage Easy, Not Mysterious

No one needs a chemistry degree to store magnesium sulfate monohydrate the right way, but patience and clear policies save time and money. Train your staff, use labeled bins, watch temperature and humidity, and trust your senses. Following these simple habits, you’ll keep your stock fresh and your workplace safe. That’s real experience talking, not just the manual.

Is Magnesium Sulfate Monohydrate safe for human or animal consumption?

What Is Magnesium Sulfate Monohydrate?

Magnesium sulfate monohydrate pops up in all sorts of products, from agricultural fertilizers to food industry uses. The version people often trust for medical or dietary purposes is called Epsom salt, though that’s actually the heptahydrate form. The monohydrate version is essentially the same compound, minus some water molecules.

Use in Food and Supplements

I’ve seen magnesium sulfate on ingredient labels, especially in foods trying to add magnesium as a nutrient. The U.S. Food and Drug Administration (FDA) has put this compound on its list of substances generally recognized as safe (GRAS) for use as a nutrient supplement in food. As long as manufacturers stick to FDA-approved amounts, most folks react to magnesium sulfate like they would to any other form of magnesium: it becomes part of the body’s mineral supply, which supports muscle and nerve function, not to mention bone strength.

Yet there’s a catch: dosing matters. Dieticians say most adults need about 310 to 420 milligrams of magnesium per day. It doesn’t take much for someone to cross that line with supplements, and too much might lead to diarrhea or cramps. With magnesium sulfate monohydrate, the story’s the same. If doses stay reasonable, people get the benefits—supporting essential body functions. Step over that line, though, and someone risks an upset stomach or worse, especially for anyone with kidney issues.

Animal Feed and Veterinary Use

Farmers and vets rely on magnesium sulfate for animals too. Feed-grade products actually do often include the monohydrate form for cattle, horses, and poultry. Veterinary guidelines say it fills in magnesium gaps and helps prevent disorders like grass tetany in cows, which can be fatal if not managed. Doses for livestock show up in veterinary textbooks and farm extension bulletins. The crucial point always comes back to proper dosing; if you toss in too much, animals experience the same stomach upset or worsening dehydration as people.

Safety Concerns

Some folks get nervous when they see “sulfate” on a label, worried about possible poisoning. Truth is, both humans and animals process the sulfate without trouble in normal amounts. That said, impurities in industrial magnesium sulfate can cause real trouble. Large producers of feed-grade and food-grade magnesium sulfate must meet strict purity standards—heavy metals or other contaminants must not exceed FDA or EU safety limits. Sticking to certified sources and trusted suppliers always protects against contamination, which matters just as much as the mineral itself.

Practical Advice

I’ve always believed in reading the fine print. If magnesium sulfate monohydrate pops up in supplements, pet food, or agricultural minerals, checking the brand’s reputation helps. A doctor or veterinarian can clear up questions about dose, since health conditions and age shift magnesium needs. Always avoid chemical-grade products from hardware or industrial suppliers, since those have not gone through food or pharmaceutical purity checks.

Magnesium sulfate monohydrate does its job for both humans and animals when used carefully and at proper levels. Overuse or using low-quality products brings risk. Good advice from qualified professionals and reliable sourcing keep things safe.

What is the difference between Magnesium Sulfate Monohydrate and other forms of magnesium sulfate?

Understanding the Basics

Magnesium sulfate isn’t a one-size-fits-all mineral. The monohydrate form, which features one molecule of water for every molecule of magnesium sulfate, stands out from its relatives like the heptahydrate (Epsom salt) and the anhydrous (water-free) version. Each version has its own character and particular uses, something I quickly learned during a stretch working with agriculture and landscaping supplies. Sometimes, missing that detail on the bag could ruin an entire crop plan or chemical mix.

What Really Changes with Hydration?

Anyone who’s ever blended fertilizer or mixed bath salts probably noticed there’s more under the surface than name alone. The “hydrate” tells you how much water is hanging onto each molecule. Monohydrate, as the name says, sticks with just one. That makes it look quite a bit different from the flaky, crystal-heavy heptahydrate. Monohydrate appears as a white powder and weighs less for every spoonful compared to the same volume of heptahydrate. Dissolving in water also creates a different experience: you need less monohydrate to get the same dose of elemental magnesium as you do with heptahydrate, which carries extra baggage in the form of water.

Why Does This Matter?

Precision counts. In agriculture, magnesium sulfate supplies magnesium for plant health. If you’re applying by weight, using monohydrate means you get more magnesium for every kilogram compared to the fluffy heptahydrate heaped into a bucket. Monohydrate lets growers save storage space and shipping cost, which can make a huge difference on a tight budget. It’s not just farmers who notice the savings—any company hauling bags of mineral powder pays less when there’s less water weight.

On the other side, the heptahydrate can be a gentler source in horticultural applications, since it dissolves rapidly in water and tends to be less “hot” for sensitive root systems. That’s a lesson that sticks after having to replant a whole row of tomatoes, all because the quicker-dissolving salt worked a little too aggressively. Epsom salt—everyone recognizes it from the pharmacy or the bathroom shelf—breaks up sore muscles without drying the skin out too fast, thanks to all that water.

Quality and Consistency in Use

Food and pharmaceutical manufacturers take a keen interest in consistency and purity. Monohydrate scores well for industries where stable storage and exact dosing are important. Less water tied up in the molecule means less chance for unwanted chemical changes during long shelf lives or temperature swings. Keeping an eye on these small details helps meet strict food or medicine regulations that don’t tolerate guesswork.

Moving Forward with Confidence

Anyone managing supply chains or lab work can avoid headaches by picking the compound that fits the scenario. It pays to know your source—big suppliers are happy to provide traceable, certified product, while fly-by-night sellers may offer guesswork in a bag. Reliable sourcing protects not just the bottom line, but public health, especially as recalls and contamination scares have made headlines across the world.

At the end of the season, getting magnesium right can be the difference between crops that thrive and crops that limp along. For anyone blending mineral supplements or running a bath, matching the form to the job means smoother results and fewer surprises. Choose wisely, ask questions, and read the label every time.

How is the quality or purity of Magnesium Sulfate Monohydrate ensured?

Why Quality Matters in Magnesium Sulfate Monohydrate

Anyone who’s worked in agriculture, pharmaceuticals, water treatment—or just about any industry that touches chemicals—soon realizes quality isn’t a formality. Magnesium sulfate monohydrate isn’t a product where “close enough” works. In agriculture, any extra impurity can stunt plant growth or build up in soil. In medicine, low-grade salts risk causing harm when used in IV fluids or nutritional supplements. With so much on the line, people like growers, doctors, and process engineers look for robustness and reliability long before the magnesium sulfate reaches them.

Quality Starts with the Raw Source

In my own experience, the fight for quality starts way upstream. Any batch starts with mining or selecting magnesium-rich minerals and acids with the lowest possible levels of contaminants—stuff like lead, arsenic, or even tiny bits of iron. Suppliers who ignore that, or try to cut corners, always wind up facing trouble down the line when buyers complain or regulators show up with a test kit.

Routine checks on incoming minerals mean nothing questionable gets into the production process. Simple seeded crystals, no unfamiliar discoloration, no off-smells—these are signs I learned to spot by sight and smell, then confirm with basic lab analysis.

Strict Process Controls in Manufacturing

Precision isn’t just a virtue; it’s locked into every batch. Proper temperature, careful pH adjustment, and exact water content give the monohydrate its typical clean crystalline look. In any busy facility, the crew follows written procedures like a playbook, avoiding even small deviations that could mess with chemical purity.

Filtration steps never get skipped. Finer filters catch stray solid bits. Only with the right controls does the solution hit the specs for magnesium and sulfate percentages. Any change stands out in batch logs—no hiding mistakes.

Lab Testing: The Checkpoint that Catches Issues

No batch gets packed without its moment of truth—a round of lab tests. Analytical methods like atomic absorption spectroscopy or ICP-OES pin down magnesium levels within fractions of a percent. Sulfate and water content show up on testing reports, as do any trace heavy metals like cadmium or mercury. Year after year, strict limits keep accident or neglect from going unnoticed.

Once I saw a plant reject a whole run over a few extra milligrams of iron. Stingy? Maybe, but that batch could have ruined a pharmaceutical ingredient order, meaning refunds or, worse, recalls. The stakes are high.

Verification by the Customer and Regulatory Oversight

The supply chain doesn’t just trust; it verifies. Bulk buyers test samples to double-check supplier paperwork. In some regions, medicine laws require magnesium sulfate monohydrate to pass specific purity rules set by the pharmacopoeia—official medical standards. That means third-party inspections, audits, and surprise tests.

Relying on one test or one certificate just leads to trouble. Ongoing training for plant workers, investments in better laboratory gear, and supplier relationships based on transparency—these measures keep the failures rare and the product trustworthy.

Better Communication and Next Steps

Mistakes tend to follow silence. Systems that give operators a way to raise concerns, daily feedback from test labs, and digital tracking of every batch all make a difference. Whenever a batch fails a test, root cause investigations and sharing the lessons with each team member close the gap. Companies sharing lab trends with big customers build trust—no one waits for a problem to blow up before fixing it.

High-purity magnesium sulfate monohydrate takes hard work and regular investment in people and equipment. Every stakeholder along the line drives that commitment, keeping the final product safer and more reliable for those who count on it.

| Names | |

| Preferred IUPAC name | Magnesium sulfate monohydrate |

| Other names |

Epsom Salt Monohydrate Magnesium Sulphate Monohydrate Sulfuric acid, magnesium salt, monohydrate Magnesium sulfate hydrate Magnesium(II) sulfate monohydrate |

| Pronunciation | /mæɡˈniːziəm ˈsʌlfeɪt ˌmɒnəˈhaɪdreɪt/ |

| Preferred IUPAC name | Magnesium sulfate monohydrate |

| Other names |

Epsom Salt Monohydrate Magnesium Sulphate Monohydrate MgSO4·H2O |

| Pronunciation | /maɡˈniːziəm ˈsʌlfeɪt ˌmɒnəˈhaɪdreɪt/ |

| Identifiers | |

| CAS Number | 14168-73-1 |

| Beilstein Reference | 120927 |

| ChEBI | CHEBI:86463 |

| ChEMBL | CHEMBL1201108 |

| ChemSpider | 164357 |

| DrugBank | DB00653 |

| ECHA InfoCard | 100.028.274 |

| EC Number | 231-298-2 |

| Gmelin Reference | 15267 |

| KEGG | C14830 |

| MeSH | D017980 |

| PubChem CID | 16211493 |

| RTECS number | OM4508000 |

| UNII | A5SYK3G668 |

| UN number | UN3077 |

| CAS Number | 14168-73-1 |

| Beilstein Reference | 120922 |

| ChEBI | CHEBI:75863 |

| ChEMBL | CHEMBL1201472 |

| ChemSpider | 150925 |

| DrugBank | DB00653 |

| ECHA InfoCard | 03e218ee-fcd1-4f7a-9eec-4a60bb4e781d |

| EC Number | 601-070-2 |

| Gmelin Reference | 10701 |

| KEGG | C14830 |

| MeSH | D002468 |

| PubChem CID | 16218582 |

| RTECS number | OM4508000 |

| UNII | ZI0P6F7IUI |

| UN number | UN3077 |

| Properties | |

| Chemical formula | MgSO4·H2O |

| Molar mass | 138.38 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 2.66 g/cm³ |

| Solubility in water | 35 g/100 mL (20 °C) |

| log P | -2.2 |

| Vapor pressure | Negligible |

| Basicity (pKb) | 8.31 |

| Magnetic susceptibility (χ) | -1.2×10⁻⁶ |

| Dipole moment | 0 D |

| Chemical formula | MgSO4·H2O |

| Molar mass | 138.38 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 2.66 g/cm³ |

| Solubility in water | 35 g/100 mL (20 °C) |

| log P | -2.2 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 7.0 |

| Basicity (pKb) | 8.31 |

| Magnetic susceptibility (χ) | '-21.7×10⁻⁶ cm³/mol' |

| Refractive index (nD) | 1.430 |

| Dipole moment | 1.73 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 121.4 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1380.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1387.0 kJ/mol |

| Std molar entropy (S⦵298) | 121.4 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1272.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1371.0 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | A12CC01 |

| ATC code | A01AB04 |

| Hazards | |

| Main hazards | May cause respiratory tract, eye, and skin irritation. |

| GHS labelling | Not classified as hazardous according to GHS |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | No hazard statements. |

| Precautionary statements | P264, P270, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-0-1-X |

| Lethal dose or concentration | LD50 Oral - rat - 3,000 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 5,660 mg/kg |

| NIOSH | MGSO4 |

| PEL (Permissible) | Not established |

| REL (Recommended) | 1 mg/m³ |

| Main hazards | May cause eye, skin, and respiratory tract irritation |

| GHS labelling | GHS07, Warning |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Not a hazardous substance or mixture. |

| Precautionary statements | P264, P270, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | 1-0-1 |

| Lethal dose or concentration | LD50 Oral Rat 5,660 mg/kg |

| LD50 (median dose) | LD50 (median dose) = 4,600 mg/kg (oral, rat) |

| NIOSH | MG 28 |

| PEL (Permissible) | PEL (Permissible) of Magnesium Sulfate Monohydrate: 10 mg/m3 (total dust), 5 mg/m3 (respirable fraction) |

| REL (Recommended) | 130 mg/kg |

| Related compounds | |

| Related compounds |

Magnesium chloride Magnesium oxide Magnesium sulfate Epsom salt Heptahydrate |

| Related compounds |

Magnesium sulfate heptahydrate Magnesium sulfate anhydrous Magnesium chloride Magnesium nitrate Epsom salt |