L-Lysine Sulphate: A Deep Dive

Historical Development

L-Lysine, an essential amino acid, began drawing attention early in the twentieth century. Nutritionists noticed livestock growth could jump with proper amino acids, but finding practical ways to get enough into animal feed took decades. L-Lysine Sulphate traces its roots back to fermentation breakthroughs in the 1970s. As fermentation tanks grew, so did the ability to produce lysine on an industrial scale. Instead of scrambling for crude sources from cow’s milk or other proteins, fermentation techniques using bacteria like Corynebacterium glutamicum opened the door for scaled production. Through refinement, producers figured out adding sulfate helped stabilize the compound, making it easier to handle, store, and mix into animal feed. Investment poured into scaling up these plants just as demand from the global poultry and swine industries surged. Decades later, production now focuses on sustainability—genetic tweaks to boost yields, energy-saving fermentation, and resource management in runoff and waste.

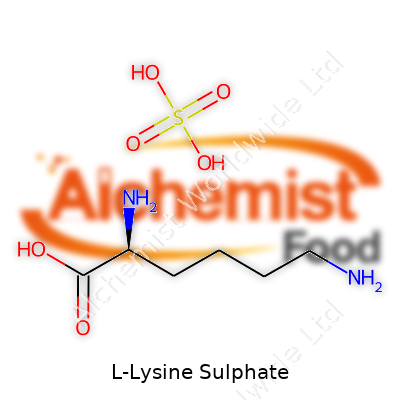

Product Overview

L-Lysine Sulphate stands out among animal feed supplements. It supplies over half lysine by weight, with the rest made up of inert ingredients and a predictable portion of sulphate. It comes in the form of a fine, free-flowing powder or granule with a pale brown color. The product can withstand rough handling, travel, and storage in humid conditions without clumping or losing activity. Farmers and feed manufacturers appreciate its simple logistical requirements—no need for refrigeration or special protection. Large volumes head to farms around the world, where they help ensure pigs, poultry, and even fish get the building blocks they need for muscle and bone.

Physical & Chemical Properties

This material presents as a light brown or almost beige powder, dense and free-flowing. Its solubility in water gives it an edge in blending—dissolving quickly and evenly through the feed. The powder resists most routine acids or bases, reflecting lysine's robust structure paired with the counteracting sulphate. Measured traditionally, a sample holds about 55% lysine on a dry basis, sometimes higher with advanced production. Moisture content weighs in around 3% to 5%. The pH runs slightly acidic, a reflection of the sulphate counter-ion, typically falling near 3.5 to 5.5 in a 10% solution. Shelf life, assuming dry conditions, can last up to two to three years before noticeable degradation. Storage in ordinary polyethylene bags or lined paper sacks suffices for transport.

Technical Specifications & Labeling

Regulatory lines stay tight around L-Lysine Sulphate quality. Most markets require certificate of analysis for each batch, showing lysine content, moisture, sulphate, ash, and heavy metal residues. Labels must state the minimum available lysine, often pegged at not less than 55%, and show relevant lot numbers, manufacture, and expiry dates. Certification from food safety bodies like FAMI-QS or GMP+ gives customers confidence, especially for feed that indirectly enters the human food chain. Stringent limits on contaminants, chiefly lead, cadmium, and arsenic, come enforced with routine sampling. Companies publishing detailed COAs with each shipment contribute to transparency and foster trust up the supply chain.

Preparation Method

Manufacturers primarily favor microbial fermentation. They culture selected Corynebacterium or Escherichia coli strains in tanks supplied with carbon sources—often cane molasses or corn syrup. With nutrients, trace elements, oxygen flow, and temperature managed, bacteria churn out L-Lysine as a metabolic byproduct. Downstream, the broth gets filtered, concentrated, and acidified. Adding sulfuric acid switches the lysine salt from hydrochloride to sulphate, favoring L-Lysine Sulphate’s longer shelf life and milder environmental profile. After crystallization and drying, the product undergoes sieving to standardize particle size. Each step faces strict microbial controls and environmental discharge monitoring.

Chemical Reactions & Modifications

L-Lysine Sulphate itself relies on an acid-base reaction, where purified lysine meets sulphuric acid, forming a stable salt. Occasionally, chemists tweak bacteria metabolic pathways for higher yields, using gene editing or promoter modification to limit byproducts and push lysine titers higher. Some research groups react L-Lysine Sulphate with enzymes to make value-added derivatives, like acetylated or hydroxylated lysines, expanding possible uses in pharmaceuticals and cosmetics. Interferences with reducing sugars, known as the Maillard reaction, can degrade lysine and must be minimized during feed processing. Optimizing reaction conditions, both in fermentation and subsequent modification, keeps waste low and product quality up.

Synonyms & Product Names

You might hear L-Lysine Sulphate called “L-Lysine sulfate” or “lysine sulphate powder.” Some suppliers shorten these to “feed grade lysine.” Rarely, technical sheets print the chemical as “(S)-2,6-Diaminohexanoic acid sulfate salt.” International trade uses the HS code 292241. Manufacturers brand their product with trade names, sometimes using terms like “AminoMax,” “LysoFeed,” or simply “LS55” as shorthand for lysine content by percentage. Synonyms in research include “Lysine 55%” and “Sulfate of L-Lysine.” Clarity on product codes and content remains key in global trade to avoid confusion, since lysine hydrochloride and monohydrate sometimes compete in similar markets.

Safety & Operational Standards

Handling L-Lysine Sulphate brings fewer hazards compared to some feed chemicals. There’s no major risk in skin or eye contact, though dust in the air can dry out mucous membranes or stir mild irritation. Workers typically wear gloves and dust masks, especially when unloading or mixing large volumes. Facilities equipped with vacuum systems and proper dust control give an extra layer of safety and keep the work area tidy. Certificates for occupational safety, like ISO 45001 or OHSAS 18001, form part of the best-run operations. Local rules cap air and water emissions, especially in fermentation discharge. Safety data sheets clearly display first-aid instructions, storage, disposal, and handling tips for non-chemists. Automated bag filling and transportation reduce human contact and injury risk.

Application Area

The broadest use hits livestock feed, where L-Lysine Sulphate supports growth and boosts efficiency. In pig and poultry farms, its inclusion helps animals convert feed to meat more quickly, cutting overall soybean and corn requirements. Fish farms supply lysine-enriched rations to handle protein gaps from shifting wild-catch sources. In dairy cattle, raising lysine intake aids milk production and calf growth. For pet food, some manufacturers incorporate it into recipes to supplement incomplete meat blends. A small but growing fraction reaches the pharmaceutical world, where specialized lysine salts treat herpes simplex infections or serve as carriers for novel drug delivery. Food technology teams investigate using L-Lysine Sulphate in functional beverages and vitamin supplements. Each segment leans on its established nutrient values and proven safety, as production keeps rising to meet global protein demand.

Research & Development

The R&D pipeline for L-Lysine Sulphate brims with challenges and opportunities. Universities team up with producers to push yields with new bacterial strains, cutting downtime in fermentation tanks. CRISPR and other gene-editing approaches target metabolic bottlenecks that once slowed output. Process engineers design continuous flow reactors to replace old batch systems, squeezing out further efficiency and savings in feedstock, water, and energy. Formulators study micro-encapsulation and coating, aiming to shield lysine from heat and shear in pellet mills. Others track the impact of particle size and carrier composition on absorption rates in animals. Researchers across continents contribute to sustainability with life cycle analysis, tracking water, energy, and greenhouse gases compared to hydrolysate production or imports.

Toxicity Research

L-Lysine Sulphate enjoys a robust track record for animal safety. Decades of studies show the supplement leaves no organ harm or abnormal growth patterns, even with long-term feeding. Acute toxicity research in rats and livestock finds the compound essentially nontoxic at practical dietary inclusion rates. The few recorded hazards link back to overdosing, where nutritional imbalances from excessive lysine crowd out other amino acids, an issue straightforwardly handled by sound ration formulation. Environmental studies on fermentation byproducts get close scrutiny. Research teams test for residual antibiotics, heavy metals, and unwanted microbial metabolites before market approval. Managers in responsible companies keep up with evolving rules to keep products safe for animals and everyone up the food chain.

Future Prospects

L-Lysine Sulphate stands ready for its next wave of innovation as global demand for animal protein shows little sign of slowing. Advances in synthetic biology, with custom-built microorganisms and streamlined fermentation, promise greater yields and lower resource draw. Companies lean into green chemistry, recycling process water, using alternative energy, and capturing waste heat to trim carbon footprints further. For emerging economies shifting toward protein-rich diets, affordable and stable supplements like lysine sulphate widen market access, supporting local food security. The pharmaceutical and biotechnology world keeps an eye on lysine-based derivatives for novel medicines and specialty formulations. With changing food regulations and increased transparency, traceability platforms and blockchain help track origins, quality, and batch data across borders. Producers and buyers alike keep adapting to sustainability challenges and shifting consumer values, cementing L-Lysine Sulphate’s role as both a staple and a frontier in industrial nutrition.

What is L-Lysine Sulphate and what is it used for?

What Makes L-Lysine Sulphate Stand Out

Farmers and feed producers talk plenty about keeping animals healthy and productive. Behind the scenes, L-Lysine Sulphate does a lot of heavy lifting in animal diets. This feed additive, made from a fermented mixture of corn and bacteria, supplies lysine – an amino acid that chickens and pigs can’t produce themselves. Add it to their meals, and you can see better weight gain, improved meat quality, and stronger bones. Growing up around family poultry farms, I remember how piglets lagged when cheaper feeds skipped out on amino acids like lysine. Once our feed supplier switched to formulas with L-Lysine Sulphate, our animals put on weight as expected, and the vet visits dropped off.

Amino acids shape everything from muscle to hormones in living things. Lysine, in particular, supports growth, tissue repair, and immune function. If animals don’t get enough, they can’t process other nutrients right – even the most expensive feed blends fall short. In commercial farming, this difference affects not just profits but also animal welfare. L-Lysine Sulphate has become a standard part of the global feed trade because it works far better than relying on whole soy or fishmeal alone.

Beyond the Feed Mill: Efficiency and Environment

L-Lysine Sulphate comes in powder form and packs more lysine per ton compared to raw soybean meal. It lets nutritionists balance rations with surgical precision. That space-saving power isn’t about packing more in trucks. It means animals get what they need and pass less nitrogen out the other end. Runoff from farms typically pollutes water with nitrogen from uneaten protein. By targeting the right amino acids, farms shrink their environmental footprint, which matters to anyone paying attention to water quality or fishing downstream.

According to research published by the Food and Agriculture Organization, using amino acids like L-Lysine Sulphate in pig and poultry feed cuts ammonia emissions. The EU has promoted these feed improvements, noting the environmental and economic benefits. Responsible production also matters. Good lysine producers run their fermenters on agricultural waste or dedicated feed crops, following food safety and sustainability standards.

Common Myths and Practical Limits

Despite the science, some buyers worry about additives with chemical names. But L-Lysine Sulphate starts with fermentation, much like how yogurt and soy sauce ferment. The resulting powder doesn’t leave drug residues or provoke allergies in animals or people. Feed safety checks have kept this ingredient mainstream for decades. Still, it isn’t a silver bullet. Good results rely on balancing lysine with other nutrients and providing clean water and shelter.

Pricing and access matter as well. Prices rise when demand spikes in China or South America, as I learned after a drought cut crop yields. Farms with tight budgets sometimes drop L-Lysine Sulphate from rations when prices soar, even if that means slower animal growth. Governments and industry groups can help by promoting research into local protein crops or streamlining lysine manufacturing.

L-Lysine Sulphate fills a clear role in feeding a growing world – responsible use, transparency in sourcing, and ongoing research will shape its future. Feed millers and farmers stand on the front lines, but everyone eats the results.

What are the benefits of using L-Lysine Sulphate in animal feed?

Supporting Health and Growth in Livestock

Protein matters in animal feed. Not all proteins break down equally, though. Most basic feed ingredients, like corn or wheat, don’t stack up well in terms of essential amino acids. L-Lysine, in particular, tends to run short in most grains. Anyone with experience raising poultry or pigs will have seen the impact—slower growth, dull coats, and sometimes a sharp drop in efficiency at feed conversion.

Adding L-Lysine Sulphate directly to rations changes things fast. Animals start putting on muscle instead of fat, and feed costs shrink because less soybean meal or fishmeal gets wasted. Both those proteins cost more and put pressure on land use. Through L-Lysine Sulphate, diets become leaner, both for the animal and the environment.

Steady Supply and Consistency in Formulation

Anyone trying to balance rations knows the struggle of keeping things consistent throughout the year. Raw ingredients swing in quality. L-Lysine Sulphate comes as a stable powder and doesn’t depend on crop yields or ocean catch. No matter if you’re mixing 50 kilograms or running a full industrial mill, its concentration won’t shift. Formulators get predictability. That means less guesswork, and fewer surprises in performance or health, whether the farm cares for a dozen birds or thousands of pigs.

Lowering Environmental Load

Animal production carries a responsibility. Excess nitrogen and phosphorus leaking into rivers, greenhouse gases, land used for soy—these problems pile up. By using targeted sources like L-Lysine Sulphate, feed protein can be dialed down without cutting growth rates. That translates into fewer nutrients wasted in manure. Studies show this clearly: with lysine-balanced rations, excreted nitrogen drops by up to 30%. Farms look beyond cost savings—they head toward meeting regulations and community expectations.

Economic Sense for Big and Small Farms

On big, commercial farms, every fraction of a percent shaved off feed costs matters. L-Lysine Sulphate lets nutritionists reduce soybean meal and balance everything tightly without costly overfeeding. Smallholders—folks mixing feed for backyard chickens or a handful of pigs—see payback too. The supplement stretches other protein ingredients further, helping animals reach market weight faster without extra cost.

Safety and Animal Welfare

Feeding animals well calls for more than just bulk calories. L-Lysine Sulphate blends smoothly into rations, and the body uses it efficiently—no strange residues or off flavors in animal products. Because the product supports immune health and lean growth, animals handle stress and vaccination better. It’s easier to keep herds healthy when they have the nutrition they require. Healthy livestock need fewer treatments and bounce back faster from challenges.

Building for the Future

Feed composition matters more every year, both for profit and social responsibility. I’ve met many livestock keepers, from small farm families to large operations. Across the board, they worry about rising costs, crop failures, and criticism about environmental impact. Shifting toward amino acid supplementation, especially with L-Lysine Sulphate, opens options to keep producing quality protein while answering these challenges. Science supports this step—field results back it up.

What is the recommended dosage of L-Lysine Sulphate for livestock?

Getting Doses Right: More Than a Supplement

Feeding livestock isn’t just about filling bellies. Each feed additive changes health, growth, and even the cost of running a farm. L-Lysine Sulphate steps into the mix as an amino acid add-on aimed at boosting muscle, growth rates, and protein use—especially in pigs, poultry, and sometimes dairy cattle. Anyone making decisions on dosage carries a big responsibility. Use too little, and animals miss their growth potential. Overdo it, and feed costs balloon without added benefit. Worse, too much can upset the natural balance and hurt both animals and budgets.

Science Behind the Dosage

Livestock can’t make lysine on their own. Grain-based feeds fall short, especially for pigs and chickens. Experts point to proper levels by tracking trials, blood tests, and years of feed research—most notably, the NRC (National Research Council) and other regional feed authorities. Pigs often sit at the center of lysine discussions because their growth hinges heavily on this amino acid.

Pulling from NRC guidelines, typical recommendations break down as follows:

- Pigs (growing-finishing): 0.8-1.1% lysine in total diet dry matter. L-Lysine Sulphate products (usually 55% pure lysine) often get blended into corn-soy feeds at rates of 3 to 8 kilograms per metric ton, based on current soybean meal content and animal growth stage.

- Poultry (broilers, layers): 0.9-1.3% lysine for broilers, slightly less for layers. That translates to about 1 to 4 kilograms of L-Lysine Sulphate per ton of feed, checked against what’s already in the base grains and protein meals.

- Dairy Cattle: Most rations rely on silage and soybean meal, but some high-production herds see benefits at inclusion rates around 0.2 to 0.3% of total ration dry matter. Here, direct supplementation doesn’t always happen unless natural lysine in homegrown feeds tests low.

Practical Value and Risks

In my experience, the best results come from regular testing—both the feed and the animals. For farms, growth spurts tell you something’s working. Feed labs help pin down actual lysine content, rather than relying on supplier sheets.

A farm that switched to precise supplementation shared its numbers: Piglets hit weight targets a week earlier, and less feed got wasted. In another situation, a poultry unit dialed up lysine for heavier breast meat, but by overshooting, saw feed bills rise with no boost in overall yield. Money went out the door for nothing extra.

Responsible Use and the Bigger Picture

Antibiotics used to cover up sloppy nutrition. Now, regulations and public demand push producers to lean on balanced diets and traceable supplements. Proper lysine helps muscle and immune health, but cutting corners or guessing with dosage risks animal stress and hits profit margins. Environmental impact enters too: Oversupplying amino acids leads to higher nitrogen waste, putting strain on local ecosystems and drawing attention from regulators.

Solutions for the Farm Gate

- Run regular feed analysis for actual lysine values, not just supplier estimates.

- Work with a qualified animal nutritionist to update rations as market feeds change—corn and soy shift in nutrient value with each harvest.

- Invest in staff training, making sure everyone on the team knows why these adjustments matter and how to catch signs of imbalance early.

- Tap technology. Automated feeders adjust mixes on demand, reducing the risk of human error in manual blending.

No shortcut beats hands-on monitoring and honest conversation with feed experts. Tracking actual animal performance, not just lab numbers, will save money and keep livestock healthy. These small steps with dosing can mean the difference between steady profit and a year of headaches.

How should L-Lysine Sulphate be stored to maintain its quality?

Why Quality Storage Pays Off

Business experience tells me one thing: overlooked storage eats into profits. L-Lysine Sulphate, a popular animal feed additive, has specific quirks. It clumps up in humid spots, and once moisture seeps in, you may end up with a sticky mess instead of a free-flowing powder. Over time, even the smallest slipup can ruin an entire batch. For any feed mill or supplement supplier, losing a pallet because of lazy storage means lost money and credibility.

Keep Moisture Far Away

Heat and water vapor work against L-Lysine Sulphate. It soaks up moisture from the air, much like table salt left out in a bathroom. I remember talking to a farmer who learned this the hard way—his sealed barrels turned gummy after a rainstorm because the storage shed leaked. Dry, well-ventilated spaces save products. Low humidity stops the clumping and stalls microbial growth. Hygrometers do the heavy lifting: a small investment, but they often pay for themselves after a single avoided spoilage.

Clean Matters As Much As Dry

Pests sniff out animal feed additives. Mice chew through weak packaging and leave behind contamination that creates health risks. I once visited a warehouse in summer, only to spot beetles crawling through a batch stored on a damp floor. Keeping floors swept, patching holes, and raising sacks off the concrete on pallets keeps supplies safe. Tough packaging with good integrity also acts as the first line of defense.

Temperature Control Makes A Difference

Direct sunlight cooks the nutrient out of the powder. Leaving sacks next to metal doors or against outside-facing warehouse walls creates hot spots. Fluctuating temperatures speed up degradation, so steady, mild conditions do the job best. Digital thermometers take out the guesswork. Facilities with some HVAC muscle get better results, but sometimes, thick insulation and shaded rooftops go a long way.

Label, Rotate and Record

Mix-ups happen, especially in busy storage rooms where similar-looking bags stack up. It pays to mark purchase dates and lot numbers front and center. Using up older inventory first (the “first-in, first-out” approach) helps avoid accidental aging that leads to loss of nutritional value. Mistakes often come down to slow rotation or skipped logs, so having easy-to-read records and clear shelf labeling takes out the confusion.

Solutions That Work

My years in feed supply have made it clear—success depends on consistency. Waterproof liners inside bags give extra protection in tricky climates. Staff training pays off by building routines around monitoring humidity, reporting leaks right away, and doing regular stock checks. New technology helps too, including smart sensors that text alerts for temperature swings or leaks, making it easier to take action before products spoil.

Trust Should Come With Transparency

Quality storage of L-Lysine Sulphate isn’t rocket science, but diligence rewards suppliers, farmers, and end consumers. The right steps support animal health and business reliability. A little extra care up front translates to safer products, fewer losses, and a reputation for doing things right.

Are there any side effects or precautions associated with L-Lysine Sulphate usage?

Unpacking L-Lysine Sulphate’s Role

L-Lysine Sulphate gets lots of attention in the world of animal nutrition, but people use it for human dietary needs, too. Folks turn to it as a supplement for muscle growth, immune support, and tackling cold sores. On the livestock side, companies blend it into feed to boost growth and protein synthesis. Some call it a game changer, but anything popular comes with questions—important ones about safety, side effects, and what taking too much might do.

Balancing Benefits with Good Sense

I remember trying lysine to help with persistent cold sores in college. Online boards were full of positive talk, and many claimed rapid healing, but not everyone shared the same story. Lysine itself, as an amino acid, plays a key part in building proteins and supporting health. The sulphate form provides a cost-effective and stable option for bulk usage, especially in agri-business. Here’s where real-world experience comes in: some users expect rapid results, but the body doesn’t follow supplement timetables.

Too much of this supplement or careless dosing can bring on its own issues. Research supports that excess lysine rarely causes serious trouble in healthy people, but some individuals run into stomach pain, diarrhea, or cramping. Some studies show links to gallstones or kidney problems if folks overdo it long-term. Pre-existing liver or kidney trouble can turn even moderate use into a gamble. Many medical sources, including the National Institutes of Health, lay it out: supplements play a minor role compared to diet and underlying health. No magic solution makes up for missing real food.

What’s Missing from the Label

Labels and promotions rarely highlight that supplements—especially amino acids—can interact with other medicines. Antiviral meds, calcium, or antibiotics like gentamicin may react with lysine intake. The risks show up most in people already managing multiple prescriptions or chronic illness. I’ve seen some friends convinced by online reviews, but they ended up facing more bloating than benefit. The clue came from their doctors, not the bottle.

Looking Out for Quality and Safety

Supplement quality varies wildly. Without clear regulation, some batches contain impurities. People taking L-Lysine Sulphate in large amounts, or every day without breaks, run an extra risk from these unknowns. Reputable companies test for contaminants, but hard evidence comes largely from third-party labs and consumer advocacy groups. It pays to check up on those reports before picking any brand.

Heading Off Trouble: Solutions That Work

Better awareness and real guidance can clear up a lot of confusion. Doctors and dietitians can help sort out the right dose and spot mix-ups with medication. The safest bet is to run supplements by a healthcare professional before starting, especially for anyone with a history of organ disease. Responsible companies should step up transparency and share real batch test results, not just marketing claims. On the user side, focus on eating a varied diet with good protein sources—chicken, eggs, beans, and dairy bring plenty of lysine.

Looking past the marketing and talking to people with real experience keeps expectations in check. Every supplement can help some people, but none offers shortcut fixes. Being honest about side effects helps everyone make better choices, for now and down the road.

| Names | |

| Preferred IUPAC name | (2S)-2,6-diaminohexanoic acid sulfate |

| Other names |

L-Lysine sulfate L-Lysine sulphate L-Lysine monosulfate Lysine sulfate Feed grade lysine sulfate |

| Pronunciation | /ˌelˈlaɪsiːn ˈsʌlfeɪt/ |

| Preferred IUPAC name | (2S)-2,6-diaminohexanoic acid sulfate |

| Other names |

L-Lysine sulfate Lysine sulfate L-Lysine monosulfate Lysine sulfate monohydrate 2,6-Diaminohexanoic acid sulfate Lysine sulfate salt |

| Pronunciation | /ˌɛl ˈlaɪsiːn ˈsʌlfeɪt/ |

| Identifiers | |

| CAS Number | 60343-69-3 |

| Beilstein Reference | 1715571 |

| ChEBI | CHEBI:57973 |

| ChEMBL | CHEMBL1201201 |

| ChemSpider | 5464299 |

| DrugBank | DB11353 |

| ECHA InfoCard | ECHA InfoCard: 03-2119980566-23-0000 |

| EC Number | 3.5.3.6 |

| Gmelin Reference | 78735 |

| KEGG | C00047 |

| MeSH | D008232 |

| PubChem CID | 23665776 |

| RTECS number | VI7525000 |

| UNII | 77V6J1A2N7 |

| UN number | UN3335 |

| CompTox Dashboard (EPA) | DTXSID7054261 |

| CAS Number | 60343-69-3 |

| Beilstein Reference | 17182 |

| ChEBI | CHEBI:61345 |

| ChEMBL | CHEMBL17837 |

| ChemSpider | 21598595 |

| DrugBank | DB00114 |

| ECHA InfoCard | 13d899bc-c7e1-4386-9971-1bc74c5bff82 |

| EC Number | 3.5.3.6 |

| Gmelin Reference | 15749 |

| KEGG | C00047 |

| MeSH | D008232 |

| PubChem CID | 22211884 |

| RTECS number | SY5600100 |

| UNII | TJ364G6D7E |

| UN number | UN3077 |

| Properties | |

| Chemical formula | C6H16N2O6S |

| Molar mass | 146.19 g/mol |

| Appearance | Light brown or yellowish powder |

| Odor | Odorless |

| Density | 0.60 - 0.65 g/mL |

| Solubility in water | Soluble in water |

| log P | -3.0 |

| Acidity (pKa) | 10.79 |

| Basicity (pKb) | 10.8 |

| Magnetic susceptibility (χ) | Diamagnetic |

| Refractive index (nD) | 1.515 |

| Dipole moment | 2.47 D |

| Chemical formula | C6H14N2O2·H2SO4 |

| Molar mass | 182.23 g/mol |

| Appearance | Light yellow or brownish powder |

| Odor | Odorless |

| Density | 0.5 - 0.8 g/cm³ |

| Solubility in water | Soluble in water |

| log P | -4.3 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 10.8 |

| Basicity (pKb) | 1.18 |

| Magnetic susceptibility (χ) | 'Negligible' |

| Dipole moment | 2.59 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 200.6 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1450.0 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3862 kJ/mol |

| Std molar entropy (S⦵298) | 221.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1630.3 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -3915.2 kJ/mol |

| Pharmacology | |

| ATC code | A16AA01 |

| ATC code | A11AA01 |

| Hazards | |

| Main hazards | May cause respiratory irritation. Causes serious eye irritation. May cause allergic skin reaction. |

| GHS labelling | GHS07; GHS05; Warning; H315, H319, H335 |

| Pictograms | GHS07, GHS09 |

| Signal word | Warning |

| Hazard statements | May cause respiratory irritation. |

| Precautionary statements | Keep container tightly closed. Store in a cool, dry, and well-ventilated place. Avoid dust formation. Avoid breathing dust. Wash thoroughly after handling. Use personal protective equipment as required. |

| NFPA 704 (fire diamond) | 2-1-0 |

| Autoignition temperature | > 410°C |

| Lethal dose or concentration | LD₅₀ (oral, rat) > 10,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Rat oral > 16,500 mg/kg |

| NIOSH | Not Listed |

| PEL (Permissible) | 10 mg/m³ |

| REL (Recommended) | 0.3 – 0.5% |

| IDLH (Immediate danger) | Not established |

| GHS labelling | GHS07, GHS08 |

| Pictograms | GHS07, GHS09 |

| Signal word | Warning |

| Hazard statements | May cause respiratory irritation. |

| Precautionary statements | Precautionary statements: P261, P264, P270, P272, P273, P280, P301+P312, P302+P352, P305+P351+P338, P312, P330, P332+P313, P337+P313, P362+P364, P501 |

| NFPA 704 (fire diamond) | 2-0-0 |

| Lethal dose or concentration | LD50 (oral, rat): > 5,000 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral rat LD50: >5000 mg/kg |

| PEL (Permissible) | 10 mg/m³ |

| REL (Recommended) | 0.7 g/kg |

| Related compounds | |

| Related compounds |

L-Lysine Hydrochloride L-Lysine Monohydrochloride L-Lysine Acetate L-Lysine Monohydrate L-Lysine Free Base |

| Related compounds |

L-Lysine Hydrochloride L-Lysine Monohydrochloride L-Lysine Acetate L-Lysine Base L-Lysine Monohydrate |