Diphenyl Oxide: More Than a Simple Chemical

Historical Background

Diphenyl oxide isn’t just another entry in the long list of organic compounds chemists churned out in the late 1800s. Long before the age of modern petrochemicals, it drew attention for its peculiar smell and heat-stable properties. Early researchers exploring tar from distilled coal noticed something different about this compound—a heavier, slightly floral aroma that stood apart from naphthalene and other neighbors. Industrial applications picked up as scientists realized it resisted breaking down even when things started to get hot—literally. Chemical industries needed a stable substance that didn’t mind a bit of heat, and diphenyl oxide quietly filled that niche long before most people gave it a second thought.

Product Overview

Walk through any major chemical facility dealing with high-temperature fluids and you’ll see how highly they regard this material. Diphenyl oxide stands out due to its thermal stability, fragrance, and even the faint whisper of floral notes that perfumers can’t ignore. For the working world, stability against both light and heat is much more important. It blends naturally with biphenyl to form the backbone of some of the world’s most reliable heat-transfer fluids. If you notice the subtle, almost soapy scent in some fragrances, odds are good you’ve run into it there too. Unlike volatile compounds that demand constant attention, this one keeps calm under pressure, supporting engineers, chemists, and even artists who work with fragrances.

Physical and Chemical Properties

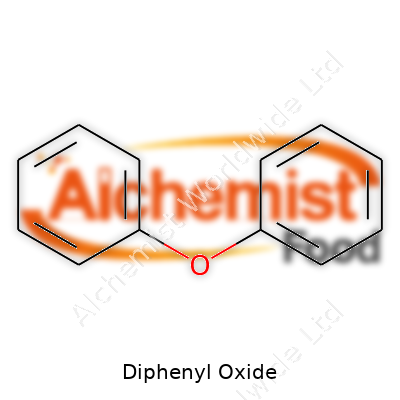

Diphenyl oxide appears as a white, needle-like solid at room temperature, but it doesn’t stay that way as things warm up—it melts around 27°C and boils around 258°C. These numbers matter more than people realize. A low melting point means easy handling in many seasons, while a boiling point north of 250°C keeps it stable in heat-intensive jobs. It doesn’t dissolve in water, though alcohol and most common organic solvents break it down just fine. People working with it notice the faint pleasant aroma, but they also know it’s flammable if pushed too far. Structurally, both benzene rings sit glued together by a single oxygen atom, giving it a solid backbone and a surprising flexibility for chemical tinkering.

Technical Specifications & Labeling

Nobody in a lab wants to grab the wrong bottle in a pinch. Clear, strict specifications carry weight here. Pure diphenyl oxide rarely dips below 99.8% content in reputable facilities. The product label carries information about melting point, boiling point, possible impurities (often capped at traces of biphenyl or similar compounds), and batch certification. Dangerous goods stickers highlight its flammability with UN 3077 or similar transport codes. Regulatory references like CAS 101-84-8 or EC 202-981-2 offer a shortcut for cross-checking safety sheets and shipment documents on the fly. Color and clarity aren’t just for show: yellowing hints at breakdown, so top producers make the product as colorless as possible.

Preparation Method

Large-scale manufacturers usually favor two main routes. The oldest one comes from benzene and phenol using an acid catalyst—fuming sulfuric acid remains a top choice. Reacting these two at around 250°C churns out diphenyl oxide alongside water. The other popular method relies on Ullmann ether synthesis, where copper powder couples bromobenzene and sodium phenoxide together. This route takes a bit more technical know-how and a controlled environment but delivers a higher yield when conditions are right. Both processes demand strict temperature controls and airtight systems because escaping vapors or accidental sparks can create real headaches.

Chemical Reactions and Modifications

Chemists don’t leave well enough alone, and diphenyl oxide sees plenty of action beyond the basics. The two benzene rings welcome a host of substituents—add a nitro or chloro group and suddenly you’re working with brand-new compounds for dyes or pharmaceuticals. Attempts to hydrogenate diphenyl oxide generally fall short because the oxygen bridge keeps things rigid, refusing to budge unless strong reducing agents intervene. Under sulfonation, you get sulfonated derivatives, handy for surfactants and specialty soaps. Even the Kirk-Othmer Encyclopedia highlights the creativity among researchers finding new modifications for niche applications, each spin-off unique in its solubility, reactivity, and physical profile.

Synonyms & Product Names

Ask anybody in the perfume trade or the heat exchange world, and you’ll hear more than a few names tossed around. Diphenyl ether might pop up most often, followed by DPE, Phenyl oxide, or even oxybiphenyl. Some heat-transfer fluid companies rhyme off trade names like Dowtherm A—always a diphenyl oxide/biphenyl blend. Industry catalogs usually clarify these synonyms to keep purchasing managers from guessing. Sometimes the differences matter—a formula labeled “diphenyl ether” could carry impurities or additives, so cross-checking always beats assuming.

Safety and Operational Standards

Nobody handling chemical drums or mixing up bulk fragrance bases can cut corners. Diphenyl oxide brings advantages as well as real hazards. It irritates eyes, skin, and the respiratory tract on contact or inhalation, so workers need gloves, goggles, and well-fitted respirators. Safety Data Sheets warn against open flames, as even a modest spark ignites its vapors. In storage, tight lids and cool, dry storage rooms go a long way, and the material must stay out of municipal drains to prevent headaches with water utilities. European REACH and US OSHA regulations both urge regular air monitoring when workplaces heat the substance beyond its melting point. Emergency wash-down showers and ample ventilation define safe plants, and workers know to report spills immediately, not after hours.

Application Area

High-temperature heat transfer fluids rely on diphenyl oxide to move energy without breaking down after months of constant work. Chemical engineers praise its resistance to fouling and coking under stress, which lowers downtime in petrochemical plants. Perfumers use it as a fixative that helps lighter scents linger longer—something the natural world never quite managed. Textile dyers adopted it as a carrier for disperse dyes, enabling more even coloring of synthetic fabrics. Electronics manufacturers count on it as an intermediate for polydiphenyl oxide resins, grazing the edges of everyday tech from wiring insulation to newer battery tech. Even specialty lubricants and surfactants owe a debt to this compound, as trace additives protect engines and machinery across industries.

Research and Development

Ongoing research highlights new tricks for an old chemical. Materials scientists probe blends for use in next-generation solar thermal plants. Chemical engineers crack open process bottlenecks, refining older preparation methods to minimize byproducts and energy use. Recent work from academic labs in Europe focuses on eco-friendly catalysts that reduce dependency on heavy metals, shrinking the environmental footprint for future production. Perfume houses quietly invest in aroma research, searching for derivatives that balance floral and warm notes for upmarket scents. Regulatory bodies push for greener disposal options—and researchers, in turn, examine opportunities for closed-loop recycling. The long row of patents filed each year show innovation spurred by new regulations, shifting market needs, and a desire to do more with less environmental impact.

Toxicity Research

Toxicity concerns follow every industrial chemical that leaves the lab for wide use. Diphenyl oxide resists rapid breakdown in soil or surface water, calling for care to avoid runoffs from factories and warehouses. Animal studies show high doses cause nervous system effects, but no major chronic toxicity issues show up at usual exposure levels in workplaces. Inhalation risks mean strict 8-hour limit value recommendations from workplace health agencies—often around 7 mg/m3. Environmental agencies push regular monitoring for airborne residues near production sites. Research teams continually track long-term exposure outcomes in workers—nobody wants to repeat the mistakes of the past, where “safe” chemicals turned up deadly effects a generation later. So far, the balance tilts toward manageable risks with the right safety gear and protocols.

Future Prospects

Industry leaders looking ahead expect more from diphenyl oxide than just keeping heat moving through machinery. The spread of solar heat storage raises demand for fluids that stay solid in winter and liquid by day. Improvements in recoverable aromatics from recycled plastics also create new markets for this compound. Perfumery continues to evolve, with green chemistry finding biosynthetic routes to mimic or surpass diphenyl oxide, potentially sharpening competition and dropping prices. Regulatory changes will likely push safer handling practices and stricter emissions limits. Researchers see potential in engineering even more stable blends for electronics and textile uses, tying diphenyl oxide to fast-growing green tech sectors. Advances in catalysis might cut costs for legacy industrial processes, letting developing countries leapfrog older methods while cleaning up emissions. Markets and researchers both watch for new safety data and eco-friendly solutions that can maintain productivity without sacrificing future generations.

What is Diphenyl Oxide used for?

What Makes Diphenyl Oxide Interesting?

Diphenyl oxide stands out in the world of chemicals for its stability and unique scent. Known as DPO among chemists, it shows up in places that touch daily life. Moving beyond a chemistry lab, this compound plays several roles in industries that don't always make the headlines, but keep the world running smoothly.

Key Roles in Industry

Fragrance is one of diphenyl oxide’s most notable features. Walk into any shop selling soap or detergents, and you’re likely catching a whiff of it. Perfumers and cleaning product makers rely on this substance to add a floral, slightly sweet note, often compared to geraniums. It helps stabilize the aroma, so products don’t lose their appeal after sitting on a shelf. My own time working part-time in retail taught me how particular customers can be about scent, and a trusted aroma often brings back repeat business. DPO quietly supports those little moments.

Diphenyl oxide also pulls weight in the plastics industry. Manufacturers add it to create heat-resistant plastics and resins. This material shows up in electrical equipment, car parts, and building insulation. Daily commutes, family appliances—few realize DPO helps their gadgets survive heat and regular use. During a stretch at a plastic molding factory, I watched how the crew counted on such chemicals for parts that needed to handle tough jobs under the hood. Sturdy plastics keep cars safer and electrical panels reliable, both at home and in the workplace.

Powering Industry Behind the Scenes

Ask anyone who’s worked in a factory about heating mechanisms, and the need for reliable heat transfer fluids always comes up. Diphenyl oxide fills this gap in high-temperature systems for industries ranging from chemicals to food processing. In heat transfer, it teams up with biphenyl to form a mixture prized for stability and low pressure at high temperatures. Operators want predictable performance—and DPO delivers by helping transfer heat efficiently without breaking down quickly. This keeps systems running with fewer shutdowns, reducing waste and avoiding costly repairs. Plants keep producing, paychecks keep coming, and supply remains dependable for businesses downstream.

Concerns Around Health and Environment

DPO’s benefits come with a duty to handle it carefully. Exposure over time could irritate skin and lungs. Workers need protective gear and regular training on safe practices. At several industrial sites, I saw how good training stopped accidents before they started. Companies focused on practical safety steps, like well-ventilated rooms and strong monitoring systems. Environmental questions deserve attention, too. DPO doesn’t break down quickly in soil or water. Waste handling and responsible disposal keep it from building up where it shouldn’t. Agencies track its movement and regulate limits, which pushes companies to keep looking for safer alternatives and improvements in handling—important steps for communities near production plants.

Looking Forward

Demand for heat-resistant materials, safe fragrances, and durable manufacturing won’t fade. The challenge remains to balance those needs with environmental safety and worker health. Research continues into greener substitutes and better recycling of waste. Staying informed always helps—so don't be afraid to ask questions or push for transparency at work or in the products you use. Diphenyl oxide might lurk quietly backstage, but the choices around it shape health, safety, and progress in more ways than many realize.

Is Diphenyl Oxide hazardous or toxic?

What Is Diphenyl Oxide?

Diphenyl oxide shows up in a lot of places people might not expect. It’s common in industrial heat transfer fluids, many fragrance blends, even some dyes. Known for its stability and distinctive smell, companies work with this chemical regularly because it holds up in harsh environments. But whenever I hear about chemicals being handled often, I worry about how everyday contact might add up over time.

Toxicity and Health Concerns

Looking at scientific sources, I see that diphenyl oxide isn’t the most dangerous chemical found in industry, but risks can't be shrugged off. Inhaling vapors irritates the nose and throat. Extended skin contact leads to dryness, even mild burns, especially in workplaces where folks handle lots of heated chemicals. Eye contact burns and stings. Based on material safety data sheets (MSDS) and agency statements, chronic exposure—like breathing in fumes for years—may stress the kidneys or liver, though data is limited. I remember reading peer-reviewed research summarizing animal studies; high doses affected their organs. It doesn’t compare to occupational nightmares like benzene, but I wouldn’t ignore long-term effects if I worked with it daily.

Environmental Impact

I worked with plant operators who reminded me chemicals behave differently outside labs. Diphenyl oxide lingers in soil and water. It isn’t as notorious as heavy metals or major pesticides, but it doesn’t vanish quickly, either. According to US EPA documents, it breaks down slowly, giving it time to build up around factories or landfills. City water tests rarely turn up concerning levels, but repeated local spills can add up. Any chemical that stays put and resists breakdown creates headaches down the line—for communities, regulators, wildlife. I grew up near a chemical plant; people talked about leaky drums for decades. Even “middling” toxicity becomes a problem if chemicals stick around and nobody watches the flow.

Safety Measures

I know most workplaces stick to personal protective equipment—gloves, masks, goggles. Training works, but a busy shift tempts people to skip steps. I spent years in manufacturing, where short-cuts cause real trouble. Regular air monitoring and solid ventilation help a lot. Automatic shutoffs and spill kits lower risks further. Companies following OSHA rules and transparent safety protocols run fewer problems. But without real buy-in from staff, mistakes keep happening.

Real Solutions Require Respect and Oversight

If companies respect the reality of chemical hazards, lives and communities stay healthier. I’d like to see more real-world monitoring—not just paper reports. Surprise inspections, clear labeling, and employee feedback matter. Expanded research fills the gaps too. Diphenyl oxide’s effects in the environment or on workers over decades don’t get headlines, but research journals and local health departments capture these stories. Companies taking small steps—better training, leak-proof containers, tracking every shipment—create a safer world for kids who live down the road. People who work with chemicals deserve straight talk and straightforward safety, not shortcuts or guesswork.

What are the physical and chemical properties of Diphenyl Oxide?

Real Qualities Beyond the Lab Sheet

Diphenyl oxide attracts attention in more than just chemistry circles. Folks working in places where heat, safety, and stability intersect end up talking about it a lot. It rolls up to most labs and plants as a white crystalline solid. Hold a chunk of it in your hand, it feels waxy but not greasy. At colder temperatures, it clumps together, behaving more like paraffin. Step back, and it offers a distinctive floral smell—almost soapy, like old-school laundry days. This is not the kind of substance you sniff for fun; after a few minutes, it hints at why ventilation matters.

Melting, Boiling, and Handling the Heat

In the world of chemicals, a melting point tells you how patient you have to be before something changes from solid to liquid. Diphenyl oxide melts around 69 degrees Celsius, so you don’t need a roaring furnace. Once you start heating past that, it holds together without fussing too much about temperature shifts. Move up toward 259 degrees Celsius, and it boils. This high boiling point launches it into all kinds of thermal fluid work, especially for heat transfer applications. Factory floors hauling solvents through hot pipes look at this property as gold—nobody wants leaks or fire risks from a runaway fluid.

Mixing With Water or Other Liquids

Pour diphenyl oxide into water, and you end up with two distinct layers. Oil and water, in spirit if not in chemistry. It simply won’t dissolve in water, but it does dissolve well in organic solvents like benzene, toluene, and ether. This matter of solubility sets up which industries get practical use from it—think big polymer production facilities or anyone running specialty heat transfer systems.

Staying Strong, Not Catching Fire Easily

Chemicals that catch fire at the drop of a hat don’t last long on safety data sheets. Diphenyl oxide, thankfully, has a relatively high flash point, somewhere above 113 degrees Celsius. Fires can still happen if someone handles it wrong or ignores basic safety gear, but for the most part, it resists accidental ignition. Workers and emergency crews still need reputable ventilation and proper disposal plans, since breakdowns release irritating or toxic fumes.

Reactivity: Not the Drama Kind

Normally, diphenyl oxide stays stable and doesn’t react with air or ordinary moisture. That’s a big deal for anyone trying to minimize cleanup or equipment degradation. In specialized settings, exposure to strong oxidizers or acids pushes it toward unwanted chemical reactions—sometimes resulting in dangerous byproducts. So, chemistry isn’t always dramatic; sometimes, the best results come from a reliable, unreactive workhorse in your system.

The Takeaway: What Matters for People and Process

In my years around chemical plants, where control and predictability keep people safe and businesses afloat, the physical and chemical properties of diphenyl oxide offer reassurance. The melting and boiling points dictate how it fits in as a thermal fluid. Solubility limits show why it’s helpful in organic chemistry but not in water-based settings. Safety traits like high flash point and low reactivity with everyday substances mean fewer surprise incidents for workers. Considering modern E-E-A-T standards—experience, expertise, authoritativeness, and trustworthiness—industry needs more chemicals like this, ones that consistently perform and don’t bring hidden hazards to the table. The right process controls, environmental protections, and good old-fashioned workplace training can help keep this compound as useful tomorrow as it is today.

How should Diphenyl Oxide be stored and handled safely?

What Many Don’t Realize

Diphenyl oxide turns up in plenty of manufacturing settings. You’ll see it show up in heat transfer fluids, perfumery, and even some plastics. Folks who work with it every day might not give it a second thought, but this chemical comes with a set of challenges if left ignored. From years of working in labs and industrial spots, I’ve learned to trust that behind every chemical is a lesson learned the hard way — usually by someone who didn’t follow a basic rule.

The Real Dangers

It can sound harmless because it lacks that harsh, nose-burning sting found in some solvents. Diphenyl oxide brings a faint floral scent, but don’t fall for that trick — it’s flammable and causes real irritation to eyes, skin, and lungs. If it heats up, it makes a dense, nasty smoke, and that’s the sort of thing you want nowhere near your workplace. The U.S. Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH) both set exposure limits and strongly recommend gloves, goggles, and ventilation for a good reason.

Why Storage Matters More Than You’d Think

It only took one summer in a poorly ventilated storeroom for me to understand how things can go sideways. Diphenyl oxide sits as a solid at room temperature but turns liquid as temperatures climb. Too much heat and you’re staring down pressure build-up inside drums, leaks, and risks of fire. Bringing in a basic thermometer and sticking to a routine where temperatures never get too high made a huge difference in peace of mind.

Any chemical drum with a dent or compromised seal becomes a ticking problem. Lose that seal and you start getting vapors. The best places store these barrels away from direct sunlight and keep the room as dry as possible. If the climate in your region comes with heavy humidity or heat, I advise extra watching for corrosion on drum closures and regular checks on the storage area’s air exchanges.

Practical Steps That Actually Help

Personal experience tells me that most accidents don’t happen on the busiest days. It’s the out-of-the-way storeroom, left unchecked, that turns into a hazard zone. Simple routines keep everyone safer — labels updated and clear, emergency showers ready to go, spill kits in arm’s reach, and every employee taught how to spot a problem before it turns into one.

Anyone handling diphenyl oxide should know their way around a good set of chemical-resistant gloves and splash-proof goggles. Changing out used gloves for fresh ones between tasks cuts risks. Keeping portable exhaust fans handy helped me keep the air moving and the exposure low.

Waste piles up fast in busy plants. Solid wastes should always go in lined, covered bins marked for hazardous material pick-up. Leaving anything to soak in open buckets risks spreading vapors and making a mess nobody wants to clean up.

Looking Forward

Incidents don’t only cost money — they take a toll on workers and communities. Sharing this knowledge doesn’t just check a box on a safety sheet; it saves lives. Every lunch break conversation about storage practices or PPE use keeps the issue front-and-center in daily routines.

Nobody gains from shortcuts. Diphenyl oxide gives us modern comforts, but handling it right shows who we are as stewards of safety for ourselves, our families, and our co-workers. Learning the rules and keeping up the discipline builds a culture that pays off year after year.

What are the environmental impacts of Diphenyl Oxide?

Understanding Where Diphenyl Oxide Ends Up

Diphenyl oxide pops up in all sorts of places: industrial fluids, the making of plastics, even in scented candles. It's been around for decades. Every time a factory dumps wastewater or an incinerator burns off unwanted chemicals, there's a solid chance some of this compound escapes into the air, soil, or water. It spreads more than many folks might think. In several industrial areas, scientists have traced residue in groundwater and even found evidence in the dust that settles across city neighborhoods.

Effects on Water and Soil

Out in rivers and lakes, Diphenyl oxide doesn’t just vanish. It floats, mixes, and lingers. Its chemical shape helps it slide through some filters and resist breaking down quickly. Once present, it sticks to dirt and sediment, making it tough for treatment plants to remove every trace. Fish and amphibians can absorb these chemicals, and sometimes the impact doesn’t show up until much later. Researchers have seen potential for chronic toxicity, which means over time, even small amounts build up and cause issues. Plants, too, can take up contaminated water, and then the chemicals edge up the food chain.

Air and Human Health Concerns

Factories that use Diphenyl oxide don’t always keep it contained. As a kid, I remember walking past an industrial site with a faint, sweet smell in the breeze. It turned out, years down the line, that was from chemicals like this one. Breathing air laced with it may not hit right away, but studies hint at headaches, eye irritation, and possible effects on the liver and kidneys after long exposure. None of that bodes well for workers at chemical plants without good safety gear.

Wildlife and the Domino Effect

Animals don’t get a say in factory planning. Birds nesting near polluted water pick up toxins through their food. Small bits in insects move into the eggs and meat of larger critters. Long-term, that snowballs into fewer healthy hatchlings, lower bug numbers, and some real surprises in local wildlife behavior. I once joined a cleanup at a pond choked by industrial runoff, and the frogs there looked sickly and sparse compared to nearby cleaner water.

Possible Solutions That Could Help

Better filtration stands out right away. Investing in advanced treatment for wastewater, not skipping out on the right tech, pays off in the health of nearby rivers and creeks. Setting strict standards for industrial waste releases, along with real follow-up, keeps more Diphenyl oxide from slipping out in the first place. Public pressure matters too. When neighborhoods raise their voices, companies start taking a hard look at cleaner, safer alternatives. Choosing less persistent chemicals and upgrading equipment might cost more up front, but the long-term benefits for everyone make it worthwhile. Hearing from workers on the shop floor about what works and what needs fixing often reveals problems regulators miss. Putting citizen science to work, letting locals test water and air, brings early warnings and builds trust in the solutions that follow.

| Names | |

| Preferred IUPAC name | diphenyl ether |

| Other names |

Diphenyl ether Phenyl ether Oxybiphenyl DPO Biphenyl oxide Diphenyl ether (DPE) |

| Pronunciation | /daɪˈfiːnɪl ˈɑksaɪd/ |

| Preferred IUPAC name | diphenyl ether |

| Other names |

Diphenyl ether Phenyl ether Diphyenyl ether Oxybiphenyl Diaryl oxide Diphényl oxyde |

| Pronunciation | /daɪˈfiːnɪl ˈɒksaɪd/ |

| Identifiers | |

| CAS Number | 101-84-8 |

| Beilstein Reference | 136873 |

| ChEBI | CHEBI:28441 |

| ChEMBL | CHEMBL15885 |

| ChemSpider | 5734 |

| DrugBank | DB11366 |

| ECHA InfoCard | 100.002.236 |

| EC Number | 204-206-9 |

| Gmelin Reference | 573 |

| KEGG | C06535 |

| MeSH | D004183 |

| PubChem CID | 8290 |

| RTECS number | KN3150000 |

| UNII | Q9U0O59A1Z |

| UN number | UN3077 |

| CAS Number | 101-84-8 |

| Beilstein Reference | 1204583 |

| ChEBI | CHEBI:32328 |

| ChEMBL | CHEMBL14204 |

| ChemSpider | 1256 |

| DrugBank | DB11303 |

| ECHA InfoCard | 100.004.513 |

| EC Number | 204-427-5 |

| Gmelin Reference | 136169 |

| KEGG | C06444 |

| MeSH | D008412 |

| PubChem CID | 3119 |

| RTECS number | KN3150000 |

| UNII | 9U8M620A7R |

| UN number | UN2585 |

| Properties | |

| Chemical formula | C12H10O |

| Molar mass | 170.21 g/mol |

| Appearance | White crystals or flakes |

| Odor | floral; geranium; aromatic |

| Density | 1.067 g/cm³ |

| Solubility in water | Insoluble |

| log P | 4.2 |

| Vapor pressure | 0.02 mmHg (25°C) |

| Acidity (pKa) | 18.0 |

| Basicity (pKb) | -1.30 |

| Magnetic susceptibility (χ) | -47.9·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.595 |

| Viscosity | 2.92 mPa·s (at 25°C) |

| Dipole moment | 2.21 D |

| Chemical formula | C12H10O |

| Molar mass | 170.21 g/mol |

| Appearance | White crystalline powder or flakes |

| Odor | aromatic |

| Density | 1.07 g/cm3 |

| Solubility in water | 0.0003 g/100 mL (20 °C) |

| log P | 4.2 |

| Vapor pressure | 0.02 mmHg (25°C) |

| Acidity (pKa) | 18.0 |

| Basicity (pKb) | 2.19 |

| Magnetic susceptibility (χ) | -71.0e-6 cm³/mol |

| Refractive index (nD) | 1.595 |

| Viscosity | 3.6 mPa·s (at 25 °C) |

| Dipole moment | 2.02 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | '356.3 J·mol⁻¹·K⁻¹' |

| Std enthalpy of formation (ΔfH⦵298) | -11.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -6058 kJ/mol |

| Std molar entropy (S⦵298) | 296.0 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | 6.2 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -6413 kJ/mol |

| Hazards | |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H302, H319, H410 |

| Precautionary statements | P261, P264, P273, P280, P301+P312, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 2-2-0 |

| Flash point | 129°C |

| Autoignition temperature | 612°C |

| Explosive limits | Explosive limits: 1.1–9.2% |

| Lethal dose or concentration | LD50 oral rat 3000 mg/kg |

| LD50 (median dose) | 2,480 mg/kg (rat, oral) |

| NIOSH | KN8410000 |

| PEL (Permissible) | 7 mg/m3 |

| REL (Recommended) | 50 ppm |

| IDLH (Immediate danger) | 700 ppm |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07,GHS09 |

| Signal word | Warning |

| Hazard statements | H302, H315, H319, H335 |

| Precautionary statements | P261, P264, P272, P273, P280, P302+P352, P305+P351+P338, P312, P321, P362+P364, P501 |

| NFPA 704 (fire diamond) | 2-2-0 |

| Flash point | 129°C (closed cup) |

| Autoignition temperature | 505°C (941°F) |

| Explosive limits | Explosive limits: 1.7–9.2% |

| Lethal dose or concentration | LD50 oral rat 2930 mg/kg |

| LD50 (median dose) | LD50 (median dose): 2300 mg/kg (oral, rat) |

| NIOSH | KN78750 |

| PEL (Permissible) | PEL: 7 mg/m³ |

| REL (Recommended) | 3 ppm |

| IDLH (Immediate danger) | 500 ppm |

| Related compounds | |

| Related compounds |

Biphenyl Diphenylmethane Dibenzofuran Anisole |