Calcium Sulfate: A Commentary on Its Journey, Uses, and Future

Historical Development

History traces calcium sulfate back to ancient Egypt, where workers used plaster of Paris—the hemihydrate form—for monuments and tomb paintings. Roman engineers shaped its use for construction, adding burnt gypsum to cement, merging traditional methods with early chemistry. Plaster casts from Renaissance medical practitioners show practical value in healthcare beyond building. Over centuries, techniques refined, moving away from simple quarrying toward purer chemical synthesis, and opening doors for new applications across industry and medicine. Plenty of industries today owe success to the steady progress in producing and understanding this mineral.

Product Overview

Calcium sulfate appears in more than one form, most commonly as gypsum (the dihydrate), hemihydrate, and anhydrite. Commercial grades come as pure white powders or solid blocks. The food industry relies on its food-grade quality to firm tofu and enrich flour with calcium. Medical teams reach for high-purity calcium sulfate to stabilize broken bones. Builders patch walls and finish ceilings with ease using the refined mineral. Even in science labs, it serves as a drying agent, pulling moisture out of the air or chemical reactions. While it looks simple, the product connects essential industries with practical results.

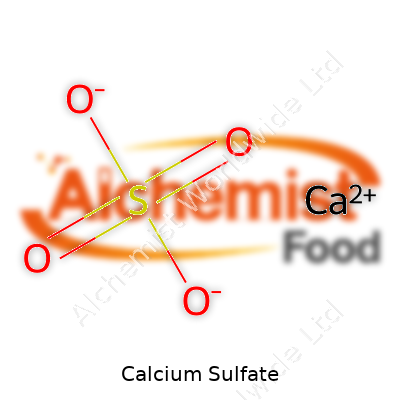

Physical & Chemical Properties

Calcium sulfate holds the formula CaSO4, delivering a high melting point around 1450°C. Water solubility stays low, less than two grams per liter. Its appearance ranges from crystalline transparent gypsum to the opaque powders used in construction. Heat causes gypsum to lose water, transforming into hemihydrate or anhydrite form, which reverses on adding water. This back-and-forth rehydration stands at the core of plaster setting. The stability, especially under most ambient conditions, means it fits in products from cement to art. Chemical inertness keeps it from reacting with most substances, important in food processing where additives risk unwanted side effects.

Technical Specifications & Labeling

Industry demands transparency, so calcium sulfate often arrives labeled with detailed purity percentages, heavy metal content, moisture levels, and mesh size. Food packs announce “food-grade gypsum” and all components comply with FCC and EU food additive codes (E516). Medical calcium sulfate comes sterilized, meeting USP quality benchmarks. Builders seek consistent setting times and particle size, crucial for reliable results in the field. Regulations spell out limits on trace metals such as lead or arsenic, and packaging requirements ensure both quality and traceability, reflecting a tightly controlled supply chain.

Preparation Method

Most large-scale production of gypsum uses either natural deposits or synthetic byproducts. Synthetic gypsum emerges from flue gas desulfurization in coal-fired power plants, cutting sulfur dioxide emissions. Ground natural gypsum heads to rotary kilns, where controlled heating pulls out water to yield hemihydrate or anhydrite. Some processes grind anhydrous material straight from mines if extreme dryness suits the final product. Careful milling and classification guarantee the appropriate fineness, whether destined for cement blending or delicate dental impressions. Additives enter at select stages, sometimes to speed up setting or tweak texture. Each route finds its place, depending on product application and local resources.

Chemical Reactions & Modifications

Calcium sulfate interacts best with water. Add water to plaster of Paris, and it shifts back to gypsum, hardening along the way—a property central to construction and medical splints. Drop acids onto it, and sulfuric acid forms, along with calcium salts, mostly of minor industrial value. Mix it with certain polymers, and the composite gains flame resistance or load-bearing qualities. In agriculture, mix it into soil to improve structure by breaking up clay without shifting pH. Chemists sometimes adjust the hydration state for specialty uses, but broad chemical reactivity sits lower compared to other salts.

Synonyms & Product Names

Names stack up: gypsum, plaster of Paris, anhydrite, calcium sulfate dihydrate, terra alba, and E516 in food contexts. Construction supply catalogs list “wall plaster” or “finishing plaster.” Scientists check for “calcium sulfate hemihydrate” or simply CaSO4. Medical packs advertise “bone void filler” or “calcium sulfate bone cement,” while brewers call for “gypsum” for water profile adjustments. Each field learns to recognize its own term, but the core compound remains the same, underlying decades of trust in performance.

Safety & Operational Standards

Manufacturers and users exercise care in handling calcium sulfate, especially as fine powders that can irritate respiratory passages or eyes. Food and pharmaceutical grades undergo extra scrutiny, with regular contaminant tests and batch tracking. Workers wear dust masks and gloves in processing plants—health and safety rules treat airborne dust as a risk factor for respiratory discomfort. Some industrial byproducts pose higher risks due to possible heavy metal admixtures, so strict regulatory checks filter out unsafe material. Waste disposal follows environmental guidelines; improper dumping can damage waterways. Responsible producers test and label every shipment for compliance, pushing accountability throughout the supply chain.

Application Area

Construction absorbs the largest volume, where plaster of Paris and wallboard shape homes, offices, and hospitals. Medical clinics use surgical-grade calcium sulfate for bone grafting and dental impressions, trusting its biocompatibility and resorbable nature. Food factories employ food-grade gypsum as a firming and anti-caking agent, especially for tofu, cheese, and baking flours. Agriculture relies on it to loosen heavy soil and replenish depleted calcium. Artisans shape statues and casts for art restoration. Even breweries and water treatment plants find value—gypsum corrects mineral balance and helps in flocculation processes. Across so many sectors, the substance proves its practical versatility.

Research & Development

Research teams continue to dig for new ways to exploit calcium sulfate. Materials scientists examine nano-sized particles to boost mechanical strength in composites. Biomedical engineers create porous bone scaffolds that speed up healing and reabsorption, substituting for metal implants. Green chemistry groups remake industrial gypsum waste into valuable products, saving landfill space. Recent patents describe blending with antimicrobial agents for safer hospital construction. Some universities probe the potential for specialty coatings, insulating materials, and even eco-friendly cements. Funding supports these shifts, aiming to push traditional uses into the modern age of high-performance materials and circular economies.

Toxicity Research

Safety records show calcium sulfate as largely nontoxic to humans, provided dust exposure stays low. Acute toxicity rates remain very low; cases of serious health impacts usually link to contaminated or misused products. Animal studies reveal little bioaccumulation or chronic harms, and it passes through the body with little change. Food regulatory bodies, after reviewing decades of feeding studies, approve its use in flour, tofu, and cheese. Environmental agencies keep watch over industrial runoff, since impurities like mercury in waste gypsum could threaten aquatic life. Research continues to track newer forms, like nanoparticles or modified composites, as unknown risks may lurk in novel applications.

Future Prospects

Demand for calcium sulfate looks set to rise, driven by green building codes and a global shift to sustainable agriculture. Builders eye wallboard that locks away carbon, while farmers opt for soil amendments that slow runoff and revive fields without harsh chemicals. The medical field expands uses in orthopedic and dental repair, anchored by growing confidence in rapid healing and absorption. Environmental tech puts pressure on plants to recycle waste gypsum, spurring new facilities and better purification. Researchers test advanced manufacturing methods, from 3D printed bone scaffolds to eco-friendly insulation. Opportunity lies in integrating digital tools for process control, tracking product from quarry to consumer. The future puts old materials to fresh uses, and calcium sulfate stands ready to meet new demands with a strong record on both performance and safety.

What is calcium sulfate used for?

Foundations in Construction

Anyone who’s worked on a renovation knows drywall. That white wallboard in homes relies on gypsum—calcium sulfate in mineral form. Hardware stores are stacked with sheets of it. Gypsum gives drywall its strength but stays light enough to carry. Carpenters and workers breathe that dust all the time. It doesn’t just stop at drywall. Crews blend it into plasters and cements, giving walls a smooth, paintable surface while keeping costs down. Builders value it for keeping construction precise, especially when quick setting makes all the difference. Even massive stadiums and hospitals use huge amounts of gypsum board, because it’s fire-resistant. When fires break out, gypsum delays the spread, giving families and firefighters precious extra minutes.

Supporting Agriculture

Calcium sulfate isn’t just about buildings. For folks on farms, it goes straight into the soil. Agricultural gypsum, as most farmers call it, breaks up tough clay ground. It’s almost a secret weapon for anyone fighting compacted fields, letting air and roots get through where crops were stunted before. Researchers at Iowa State found that using calcium sulfate helped fix soil structure and boost yields. It’s not a fertilizer in the traditional sense; plants don’t eat it for the nutrients. What it does is make other nutrients—like nitrogen—work better in the soil. In places where fields get salty or fertilizers create a buildup, it helps flush out unwanted chemicals, protecting crops and water supplies.

Daily Food Additive

People eat calcium sulfate more often than they realize. It’s in tofu, making the white blocks hold together at the store. Cheese makers rely on it to help curdle milk and keep textures right. Even in everyday bread, bakers turn to calcium sulfate to improve the dough. The FDA recognizes it as safe, so nobody worries about trace amounts in their lunch. From personal experience, walking through a tofu shop or dairy, the use of “gypsum” gets almost routine. Without it, a lot of vegetarian protein options would fall apart or get watery. The food industry has leaned on it for decades, long before clean-label trends took off.

Cleaner Water, Safer Medical Supplies

Calcium sulfate also filters water. Industrial setups pour it into tanks, where it soaks up impurities and clears out metals that would otherwise pollute rivers. Water works crews using gypsum help cities keep up with strict EPA standards. Even in medicine, it pops up. Surgeons use specialty forms to help heal bones or fill gaps left by trauma. It dissolves slowly, supporting tissue regrowth. Scientists keep improving these uses, hoping one day it might shorten hospital stays or lower infection rates after surgery.

Looking Ahead: Reliable and Practical

There’s no drama to calcium sulfate. It just works, quietly improving construction, farming, food, and health. Costs stay low and supplies haven’t run short. As a practical tool, it solves more problems than most people ever notice. One thing our experience tells us: making the most of these unsung compounds keeps progress rolling, whether building homes, growing food, or looking after health.

Is calcium sulfate safe for human consumption?

Understanding Calcium Sulfate's Everyday Presence

Calcium sulfate often slips under the radar—even though it pops up in common foods, tablets, and even some bottled drinks. Known better in the kitchen as “gypsum,” this additive has made its way into things like tofu, baked goods, and even some craft beers. People usually don’t notice it, but food makers like calcium sulfate since it offers a source of calcium without a strong taste. It keeps flour from caking and helps beer clear up, so it isn’t just science speak on the label.

What Science and Regulators Say

The U.S. Food and Drug Administration lists calcium sulfate as “generally recognized as safe” for food. So does the European Food Safety Authority. These agencies rely on toxicology reports that set limits based on animal studies and human observation. In regular doses found in food, calcium sulfate hasn’t shown negative health effects. Most experts trace its safety back to its inability to dissolve much in water. It just passes through your system and doesn’t build up in your tissues.

People eat calcium in different forms all the time, whether in dairy or plant-based foods. Calcium sulfate gives another option, especially for vegans or people avoiding dairy. Nutrition reports show a half-cup of tofu made with calcium sulfate offers about as much calcium as a similar amount of milk. That means it can actually help fill in nutrient gaps without adding weird flavors or side effects.

Addressing Potential Health Concerns

Some folks worry over minerals showing up in their food, usually after seeing a long ingredient list. Additive anxiety isn’t always misplaced—food safety problems make headlines now and then. But for calcium sulfate, the facts are pretty reassuring. Scientists haven’t linked it to cancer or digestive problems when eaten in amounts found in food. Only very high doses, far above what anyone eats, have caused mild digestive upset during animal tests.

Even the allergic crowd doesn’t often react to calcium sulfate. Unlike sulfites, which can set off hives and wheezing in sensitive groups, sulfate pops up everywhere in the body. It doesn’t trigger reactions in the same way. Anyone with a rare metabolic disorder called “hypersulfatemia” might want to check with a doctor, but for most people, that risk stays low.

What’s Next for Food Additives?

Food safety marches forward because watchdogs keep re-evaluating even old additives. Researchers use laboratory tools and global data networks that barely existed one generation ago. Some additives have lost their green light as new evidence showed hidden risks. Calcium sulfate keeps its status, but watchdog agencies review new research so nothing slips through the cracks.

For concerned eaters, transparency helps. Reading food labels gets easier every year, and consumer pressure keeps pushing makers toward clearer language and safer options. If anything changes with calcium sulfate, public health agencies spread the word through recalls and advisories. That’s worked for decades with everything from lead paint to trans fats.

Smart Ways to Approach Food Choices

Everyone needs minerals, but not everyone wants them from a food packet. Eating fresh, whole foods makes sense, yet packaged foods sometimes fill key gaps. Nobody would want hidden hazards in the food supply. Calcium sulfate, with its clean safety record and cautious oversight, shows how a food ingredient can quietly do good without drawing much attention. Makers and regulators must still earn trust by explaining the facts and pulling additives if dangers pop up. People stay in the safest spot by checking labels, listening to public health advice, and finding balance on the dinner plate.

What are the common forms of calcium sulfate available?

Gypsum: A Workhorse in Construction and Farming

Walk into any construction site or home improvement store and you’ll find bags stacked with gypsum, a soft mineral made mostly of calcium sulfate dihydrate. People call it plaster of Paris once it gets calcined—a simple heating that drives off water, leaving a powder you add water back to for molding, casting, or patching walls. The practicality of gypsum sits in its ability to patch cracks and coat surfaces smoothly. It hardens quickly and holds paint well, so folks in building and renovation count on it. Beyond walls, farmers rely on gypsum as a soil conditioner. It brings calcium and sulfur to plants without making soil more alkaline, so high-yield fields and green lawns stay productive. According to studies from the University of Georgia, gypsum also fights soil compaction, improving water infiltration, which helps crops take root.

Anhydrite: The Dry Variety

Anhydrite skips the water content that makes gypsum so forgiving. It’s all calcium sulfate, tightly packed and much harder. You’ll see it on blueprints for flooring and specialty cements. Builders use anhydrite screeds for underfloor heating projects because they flow easily into place and don’t crack as concrete often does when heated up and cooled down daily. It sets slowly, which gives workers extra time to get everything level before it locks in solid. Anhydrite deposits also supply the world with raw calcium sulfate for processing into other forms. Some regions of Europe have long histories of mining it, feeding demand that stretches far from the quarry itself.

Hemihydrate: Plaster of Paris by Another Name

Switch up the heating process, and that gypsum turns into calcium sulfate hemihydrate. Folks know it as plaster of Paris, and just a splash of water brings it to life. It sets fast—minutes, not hours—so artists and doctors alike reach for it. Plaster casts fix broken bones thanks to its snug fit and fast hardening. Artisans pour it into molds to make intricate shapes. Dental labs rely on hemihydrate plaster for creating sturdy molds and models, which need both detail and speed. Having practiced casting with it in art school, I’ve seen its versatility firsthand. It lets you pull detailed sculptures, mementos, and repairs from near-improvised molds, turning a powder into something solid to hold and keep.

Synthetic Calcium Sulfate: Meeting Modern Industry

Power plants produce synthetic calcium sulfate every time they scrub sulfur out of smokestacks—more specifically, out comes a byproduct called flue-gas desulfurization (FGD) gypsum. This source now supplies a huge share of the material for wallboard, reducing landfill waste from power plants in the process. Manufacturing stats from the U.S. Gypsum Association reveal that more than half the wallboard made there uses synthetic gypsum. Its purity and consistency support quality control, something builders and regulators demand.

Why It All Matters

People talk about calcium sulfate like it’s just another chemical, but these different forms touch daily life more than most realize. Farmers rely on gypsum to balance soil and boost yields. Contractors depend on plaster and screeds to build our walls and floors. Hospitals turn to quick-setting plaster for patient care. Industry pushes waste into a resource, cutting environmental impact and keeping homes affordable. Each version comes with practical reasons for its use, shaped by real needs and long experience. Finding the right calcium sulfate depends on what job needs doing, whether it’s nurturing plants, mending limbs, or building the places where we live and work.

How is calcium sulfate used in food products?

What Sets Calcium Sulfate Apart?

Calcium sulfate pops up in many foods most people eat every day. As someone who keeps an eye on ingredient lists out of curiosity and concern, I’ve often wondered what it actually does beyond being just another additive. In most grocery stores, you’ll find it listed on bread, tofu, canned vegetables, and even some candies. It goes by a few names, but it plays an unmistakable role—in helping food hold together and supplying crucial minerals.

Calcium’s Quiet Contribution to Diet

Growing up in a household where osteoporosis was always looming as a family concern, enriching foods with additional calcium mattered. Calcium sulfate brings a stable, tasteless way to deliver calcium, making a difference in diets that run low on the mineral. The FDA recognizes it as safe, and food regulators worldwide keep it under close watch because it can help fill nutritional gaps in a way that doesn’t throw off the flavor. According to NIH data, about 40% of people in the U.S. struggle to get enough calcium, sometimes because of lactose intolerance or a vegan diet. Adding calcium sulfate gives food makers flexibility to create fortified options, like plant-based milks or gluten-free products, where traditional sources fall short.

Beyond Nutrition: How It Shapes Our Food

Its use goes beyond boosting calcium. Bakers rely on calcium sulfate as a firming agent in breads and dough conditioners. Anyone who’s made bread at home knows how easy it is for dough to slump or fall flat. This mineral keeps structure consistent, especially in mass production. It lets packaged breads last longer without feeling gummy or heavy. In tofu production, calcium sulfate turns soy milk into curds, helping create that tender bite. Tofu texture can shift quite a bit based on what coagulant goes into the tank—this ingredient produces a clean taste and an even set, much like the tofu you’d find in a family-run Asian market.

The Need for Transparency and Trust

Consumers have grown more cautious around additives in the past decade, inspired by concern about processed foods and mystery ingredients. Conversations with dietitians have shown me most skepticism comes from a lack of clear, honest information. It’s on brands to list what’s in their products and explain how these ingredients work. Trust deepens when companies give straight answers. In the case of calcium sulfate, decades of studies from groups like the Institute of Food Technologists and peer-reviewed research underline its safety at the levels used in foods.

Weighing Solutions for Better Food Decisions

For folks worried about the potential side effects of too many additives, demanding open communication and supporting stronger food labeling laws helps everyone. Pushing for more funding around independent research—beyond studies funded by the processed food industry—could lead to new options for food manufacturers and consumers with concerns. Simple educational resources, like public health campaigns and ingredient explainers on packaging, can cut through misinformation.

As someone who’s spent years caring for older relatives and kids, confidence in everyday groceries matters. Knowing exactly why a mineral like calcium sulfate lands on the label helps families balance the benefits and make smarter choices about processed foods.

What are the side effects of calcium sulfate?

What is Calcium Sulfate?

Calcium sulfate shows up in a surprising number of places: from plaster to baking powder, to medicine. In the food world, it’s used to firm up tofu or as a baking agent. Builders know it as gypsum in drywall. Health professionals sometimes use it in capsules or dental casts. Because of this wide use, questions about side effects aren’t just theoretical—they matter in real life, not just in chemistry class.

Side Effects in Medicine and Supplements

Over the past few years, there’s been a rise in calcium sulfate being used in medicine, especially as a supplement or as a delivery method for medication. For most healthy adults, taking small amounts of calcium sulfate in food or as a filler in pills causes few problems. Still, trouble can show up if someone is sensitive, allergic, or takes more than the recommended amount. I’ve spoken to people who tried supplements without reading the label, not realizing that excess calcium in the body can lead to constipation, or, in rare cases, kidney stones and stomach pain. Too much can also interfere with how the body absorbs other minerals such as magnesium or zinc.

Reactions You Might See

Some people with a history of allergies don’t respond well to additives, including calcium sulfate. Although severe allergic reactions seem rare, if you have asthma or eczema, it’s smart to pay extra attention. I remember a friend who, after eating a new protein bar, broke out in hives. It turned out the culprit wasn’t calcium sulfate, but that experience made us dig deeper into food labels and added ingredients.

Doctors have recorded a few cases where people developed irritations or mild swelling from direct medical exposure such as dental cement containing calcium sulfate. Compared to some chemicals, these odds are low, but it’s worth mentioning.

Food Additive Concerns

People sometimes worry: If calcium sulfate’s in building materials and food, can eating it be safe? The FDA and the European Food Safety Authority have both reviewed studies—over and over, the doses found in food aren’t linked to major problems. Giant spoonfuls or chronic overuse tell a different story, but normal use in tofu, flour, or canned goods hasn’t been shown to build up in the body or cause toxicity. Past debates about “food grade” versus “industrial grade” matter here. Only food-grade calcium sulfate—a purified version—gets approval for eating.

How to Minimize Risk

People can take a few steps to avoid unwanted side effects. First, always read supplement labels. Anyone with a history of kidney disease or calcium metabolism disorders should talk to a doctor before trying products high in calcium, including those with calcium sulfate. Parents of young children need to keep an eye on packaged foods, since calcium can sneak into unlikely places.

Healthcare workers ought to flag possible allergies before using medical products containing calcium sulfate. At home, using natural, unprocessed foods limits exposure to a lot of additives—worry less about gypsum in tofu and more about overdoing supplements without medical advice.

What Research Shows

Most studies suggest side effects remain uncommon and mild for those following usual diet habits. Reports show no major health risks for people eating everyday servings. That’s good news, but science always offers room for more knowledge, especially for kids, pregnant women, or people with rare health conditions. Any health decision—especially with supplements—works best with honest advice from experienced medical professionals and smart decisions at the grocery store.

| Names | |

| Preferred IUPAC name | calcium sulfate |

| Other names |

Gypsum Terra Alba Plaster of Paris Anhydrite Drierite |

| Pronunciation | /ˈkæl.si.əm ˈsʌl.feɪt/ |

| Preferred IUPAC name | calcium sulfate |

| Other names |

Sulphuric acid calcium salt Calcium sulphate Anhydrous gypsum Terra alba Drierite Gypsum Plaster of Paris |

| Pronunciation | /ˈkæl.si.əm ˈsʌl.feɪt/ |

| Identifiers | |

| CAS Number | 7778-18-9 |

| Beilstein Reference | 3589280 |

| ChEBI | CHEBI:31344 |

| ChEMBL | CHEMBL1201191 |

| ChemSpider | 21507 |

| DrugBank | DB09361 |

| ECHA InfoCard | ECHA InfoCard: 029-004-00-0 |

| EC Number | 231-900-3 |

| Gmelin Reference | 69536 |

| KEGG | C01537 |

| MeSH | D002121 |

| PubChem CID | 24497 |

| RTECS number | WN5070000 |

| UNII | WAT666S2JV |

| UN number | UN3077 |

| CAS Number | 7778-18-9 |

| Beilstein Reference | 100930 |

| ChEBI | CHEBI:31344 |

| ChEMBL | CHEMBL1201759 |

| ChemSpider | 8415 |

| DrugBank | DB09311 |

| ECHA InfoCard | ECHA InfoCard: 029-004-00-0 |

| EC Number | 231-900-3 |

| Gmelin Reference | 1746 |

| KEGG | C00624 |

| MeSH | D002121 |

| PubChem CID | 24497 |

| RTECS number | WS6920000 |

| UNII | V9V9012K0T |

| UN number | UN number: "UN1379 |

| Properties | |

| Chemical formula | CaSO4 |

| Molar mass | 136.14 g/mol |

| Appearance | White, odorless powder or colorless crystals |

| Odor | Odorless |

| Density | 2.96 g/cm³ |

| Solubility in water | 0.21 g/100 mL (20 °C) |

| log P | -2.0 |

| Vapor pressure | Negligible |

| Basicity (pKb) | 11.91 |

| Magnetic susceptibility (χ) | `-28.4·10⁻⁶ cm³/mol` |

| Refractive index (nD) | 1.524 |

| Dipole moment | 3.07 D |

| Chemical formula | CaSO4 |

| Molar mass | 136.14 g/mol |

| Appearance | white crystalline solid |

| Odor | Odorless |

| Density | 2.96 g/cm³ |

| Solubility in water | 0.21 g/100 mL (20 °C) |

| log P | -2.0 |

| Vapor pressure | Negligible |

| Acidity (pKa) | > 7.7 |

| Basicity (pKb) | 6.7 |

| Magnetic susceptibility (χ) | '-34.0·10⁻⁶ cm³/mol' |

| Refractive index (nD) | 1.576 |

| Dipole moment | 0.0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 107.2 J/(mol·K) |

| Std enthalpy of formation (ΔfH⦵298) | -1434 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1434.0 kJ/mol |

| Std molar entropy (S⦵298) | 107.2 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1432 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1444.0 kJ/mol |

| Pharmacology | |

| ATC code | V07BB |

| ATC code | A12AX04 |

| Hazards | |

| Main hazards | May cause irritation to eyes, skin, and respiratory tract. |

| GHS labelling | Not classified as a hazardous substance or mixture according to the Globally Harmonized System (GHS). |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Calcium sulfate is not classified as hazardous according to GHS (Globally Harmonized System); it typically does not have any hazard statements. |

| NFPA 704 (fire diamond) | 0-0-0 |

| Lethal dose or concentration | LD50 Oral Rat: > 3000 mg/kg |

| NIOSH | WF9580000 |

| PEL (Permissible) | 15 mg/m3 |

| REL (Recommended) | 60 mg/kg |

| Main hazards | Not a hazardous substance or mixture. |

| GHS labelling | GHS07; Warning; H315, H319, H335 |

| Pictograms | GHS07 |

| Signal word | No signal word |

| Hazard statements | No hazard statements. |

| Precautionary statements | If medical advice is needed, have product container or label at hand. Keep out of reach of children. |

| NFPA 704 (fire diamond) | 0-0-0 |

| Lethal dose or concentration | LD50 Oral Rat: > 3000 mg/kg |

| LD50 (median dose) | LD50 (median dose): > 2000 mg/kg (oral, rat) |

| NIOSH | WFJ366500 |

| PEL (Permissible) | 15 mg/m3 |

| REL (Recommended) | 600 mg/kg |

| Related compounds | |

| Related compounds |

Calcium chloride Calcium sulfite Calcium carbonate Calcium phosphate Calcium hydroxide |

| Related compounds |

Anhydrite Calcium chloride Calcium sulfide Plaster of Paris Gypsum |