Ammonium Sulphate: A Deep Dive into an Everyday Essential

Historical Development

Farmers across the world started using ammonium sulphate more than a century ago. After the industrial revolution, coal gas plants began capturing ammonia as a byproduct, which led chemists to convert this resource into fertilizer by reacting it with sulphuric acid. Before synthetic nitrogen production took off, natural ammonia sources were limited, but the Haber-Bosch process flipped that dynamic. By the 20th century, ammonium sulphate firmly established itself in agriculture and industry. In my own experience growing up among small-scale farmers, a bag of this fertilizer sometimes held a family's hopes for the season’s harvest. Without flashy advertising or government programs, word-of-mouth carried its reputation for reliability long before the internet spread news at lightspeed.

Product Overview

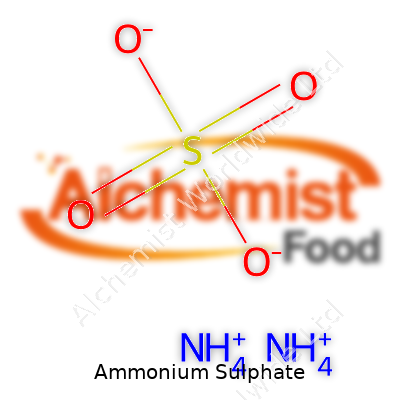

Today, ammonium sulphate comes as a white, free-flowing crystalline solid or, less commonly, as a granulate. Its chemical formula, (NH4)2SO4, reflects a simple pairing between ammonia and sulphuric acid. Packed in heavy-duty sacks, these crystals blend easily with most soils and mix readily with water. With about 21% nitrogen and 24% sulphur, this compound enriches fields and supports plant growth, especially for crops craving both nutrients. I’ve seen how steady demand has kept the price relatively stable, making ammonium sulphate a fixture even in low-income agricultural regions. Major suppliers stick to this basic, effective formula, since yield results tend to justify its persistent use among growers.

Physical & Chemical Properties

Physically, ammonium sulphate forms small, colorless crystals that dissolve easily in water but barely budge in alcohol or acetone. It holds up against gentle heating but breaks down into ammonia and acidic gases at higher temperatures, releasing a sharp smell. Chemically, it won’t combust, but it reacts firmly as a salt, drawing water from the air and lowering soil pH over time. This acidic effect proves valuable in some alkaline soils but becomes a drawback where acidity builds up already. From personal observation, dusty crystals can clump in humid storerooms without sealed bags, so proper storage remains a constant battle in rainy climates. Ammonium sulphate does not corrode containers aggressively, unlike some other fertilizers, so farmers appreciate the longevity of their bins and spreaders.

Technical Specifications & Labeling

Industry standards typically require ammonium sulphate contain a minimum 20.5% nitrogen and 23.5% sulphur. Impurity levels for arsenic, lead, mercury, and cadmium remain low, meeting food safety needs and local environmental codes. On each package, clear labeling identifies the net weight, chemical content, manufacturer details, and any hazard pictograms. Consistent labeling supports safe use and helps buyers compare products for application rates and safety data. In smaller supply shops, handwritten or faded labels still pop up, raising risks of misuse—especially where smallholder farmers operate with low literacy rates or limited regulatory oversight. Regular talks with extension officers taught me that better labeling can cut down misapplication accidents, so pressure always mounts for clearer, multilingual product information.

Preparation Method

Modern factories typically manufacture ammonium sulphate through direct neutralization: hot ammonia gas meets concentrated sulphuric acid under controlled cooling, crystallizing out pure product. Variations use recovered waste streams from steel manufacture, where flue gases billow with ammonia that scrubbers capture and recycle. This circular approach keeps factory waste down while pushing fertilizer output up—a double win in crowded markets. From conversations with plant workers, on-the-ground safety depends on tight containment of fumes and acid handling, so industries invest heavily in scrubbers, protective gear, and automatic systems. Where smaller facilities cut corners, tales of injuries or toxic releases spark outrage and sometimes new government crackdowns.

Chemical Reactions & Modifications

Ammonium sulphate enters a series of reactions in soil, breaking apart to feed plants with free ammonium ions and sulphate anions. Bacteria in the earth convert ammonium into nitrate, releasing hydrogen ions and acidifying the ground further. Lab chemists tweak the molecule by blending it with urea or phosphate salts to craft compound fertilizers tailored to regional crop needs. Some formulations coat granules to slow down nutrient release, reducing leaching and waste. Others mix trace elements—like zinc, boron, or molybdenum—that unlock micronutrient deficiencies in stricken plants. These innovations spring from feedback loops between field trials and lab analysis, where product tweaks tangibly boost yields or plant health.

Synonyms & Product Names

Depending on the context, ammonium sulphate gets called "ammonium sulfate," "masala," or even "sal ammoniac" in older texts, though that last term now fits a slightly different mineral. In China, many farmers just translate it as "two-element fertilizer," referencing its dual nutrient delivery. Commercial names include "Actamaster," "Ammosul," and plain "AS-Agro," but most buyers know it by the chemical name and the promise of better crops. Among industry old-timers, the nickname “white salt” pops up, describing its chalky, innocent-looking appearance that hides its punchy performance.

Safety & Operational Standards

Handling ammonium sulphate demands common-sense safety. Contact rarely irritates skin, but dust clouds sting eyes and can trigger coughing fits if inhaled. Workers store it away from flammable organic matter or strong bases, since accidental mixing sometimes triggers smelly or corrosive emissions. Warehouses limit stacking height to prevent bag rupture or collapse. In my own work, training sessions stressed regular hand washing, fitted dust masks, and keeping stock dry—simple steps, yet skipping these basics opens the door to accidents or injuries. Regulations in most exporting countries tightly control residue levels, packing integrity, and transport rules, so the industry continually trains staff and audits supply chains.

Application Area

Most of the ammonium sulphate ends up in fields growing rice, wheat, soy, and a spectrum of other crops. Regions plagued by sulphur-deficient soils, like parts of Asia or Africa, depend on it to support strong yields. Horticultural operations use it to green lawns, feed vegetables, or repair patches of turf. In industrial circles, the compound shows up as a food additive (E517), a fire retardant component, and a protein precipitation agent in labs. Each sector relies on ammonium sulphate for different reasons—in the countryside for growth, in the city for chemistry, and on the factory floor for cost-effective ingredient management. The many faces of this white powder reflect a surprising versatility that established it as a workhorse across the economy.

Research & Development

Research pours into reducing the environmental footprint of ammonium sulphate. Studies test coated variants and urease inhibitors to slow nitrogen loss, aiming for more food per kilogram and cleaner rivers. Agronomy labs examine how blends with organic compost or biochar can lock in nutrients longer, saving money and reducing run-off. Factory R&D teams explore greener production using alternative acid sources or tighter ammonia recovery setups. Field demonstrations link up with data analytics so farmers can dial in application rates based on satellite imagery or real-time soil tests. At every step, the pressure stays high: feed more people, pollute less, adapt to climate shifts, and avoid regulatory fines.

Toxicity Research

Ammonium sulphate’s toxicity sits low for humans compared to some agricultural chemicals. Large accidental exposures bring nausea, headache, or respiratory problems, especially for workers stuck in enclosed spaces. Chronic overapplication makes soil too acidic, which can harm microbial health and lead to toxic aluminum buildup—issues now highlighted in both academic papers and extension bulletins. Veterinarians warn that grazing livestock sometimes show mild symptoms if fed hay treated with heavy doses, but such cases usually clear up with clean water and proper pasture management. Ongoing toxicology keeps sharpening safety margins, backed by real-world accident reports that flag weak points and inform training.

Future Prospects

Demand for ammonium sulphate looks steady, if not rising, as developing regions expand fertilizer use to feed booming populations. Advances in sustainable agriculture—such as precision farming, satellite-guided spreading, and slow-release coatings—promise smarter use and less pollution. Environmental groups keep lobbying for alternatives, focusing on organic amendments and renewable inputs, but cost and availability issues still push many buyers back to ammonium sulphate. I predict stronger oversight, tighter emission controls in factories, and new recycling initiatives that trim the waste loop. From the classroom to the countryside, honest education and consistent regulations will keep this compound vital yet responsibly handled in the decades to come.

What is ammonium sulphate used for?

Getting Down to the Roots

Ammonium sulphate has stuck around on farms for good reason. Farmers trust this pale salt to give their crops steady nitrogen and sulfur—two nutrients soils can run low on once harvest season wraps up. I’ve grabbed many a fifty-kilo bag off the back of a truck, because ammonium sulphate delivers real results in green fields and bigger yields. Crops often tell the story: yellowed corn leaves grow a healthy shine, and a patchy grassland fills in fast after a dose of this fertilizer. Plenty of research backs this up—adding ammonium sulphate supports strong plant growth where soil tests come back sulfur deficient, which happens more than people might think, especially where older pesticides aren’t used anymore and acid rain has dropped off.

Why Farmers Count On It

Ammonium sulphate’s main job? Giving farms a solid, predictable source of nitrogen. This matters if you’re growing wheat, corn, rice, or vegetables. Nitrogen lets plants build proteins, and the added sulfur helps them pull that off, especially where sandy soils or heavy rains wash stuff away. Unlike other fertilizers, this one lowers soil pH a bit. That actually helps in spots with alkaline dirt where nutrients can get locked up. Farmers in the Midwest, California, or tropical climates where leaching happens use ammonium sulphate for this effect. It’s not just a commercial fields thing, either. I’ve used it for backyard tomatoes and garden beds to keep plant leaves deep green and healthy, especially early in the season.

Beyond the Farm: Industry at Work

This compound steps outside agriculture, too. Water treatment plants use ammonium sulphate to remove unwanted minerals and keep drinking water safe. Textile factories and food manufacturers rely on it as a food additive or processing aid, and the steel industry uses it in flameproofing and as a component in cooling baths. These jobs don’t make the headlines, but they’re a big reason ammonium sulphate lands on train cars heading far from farm country. None of this surprises me after seeing how reliably it works in the soil—the same predictable chemistry helps in factories and municipal plants where consistency is the name of the game.

Is There a Downside?

Big wins sometimes come with real-world headaches. Overuse of ammonium sulphate can push too much nitrogen or sulfur into waterways. Runoff leads to problems for rivers and lakes. I’ve seen algae bloom out of control in farm ponds, a direct result of careless fertilizer handling. Soil itself can turn sour if you add more acidifying fertilizer than the plants can use. Some environmental groups and university extension folks now urge careful soil testing before application. That makes sense to me—guessing means wasted money and pollution, while targeted use keeps both profits and wildlife healthier.

Smarter Ways Forward

Smart use comes down to knowing exactly what your field or factory needs. Precision agriculture uses GPS and soil sensors, so only spots needing boost get ammonium sulphate. Buffer strips next to waterways, cover crops in winter, and strict storage rules all help prevent runoff. In cities and industry, switching to closed systems or recycling effluent cuts pollution. It’s not a magic bullet, but everyone—from local farmers to global companies—can make simple changes that add up. Lessons from hands-on work with this fertilizer keep proving it: stewardship matters if we want to keep reaping the benefits of useful tools like ammonium sulphate.

Is ammonium sulphate safe for plants and soil?

Understanding What Ammonium Sulphate Does

Ammonium sulphate keeps popping up in gardening circles and on farms across the world. It’s a common fertilizer. People like it for giving a strong punch of nitrogen and sulfur to crops, which pushes along green growth and helps plants make protein. Out in the fields, I’ve seen farmers trust it for rice, wheat, and even vegetables. There’s no question it perks up growth in the short run. But the question that makes gardeners and professionals pause is, “Is this stuff actually safe for my soil and the living things in it?”

The Short-Term Impact on Plants

You spread ammonium sulphate, and most plants respond quickly. The leaf color deepens. Growth speeds up. Where soils lack nitrogen—many gardens in my area—plants just look healthier after a dose. Nitrogen boosts leaf and stem production. Sulfur helps plants process other nutrients. In practical terms, if your garden looks yellowed or sluggish, this fertilizer brings signs of life in just a few weeks.

Potential Soil Risks From Regular Use

There’s a catch. Ammonium sulphate brings along its own set of problems if used carelessly or in bulk. Every time you add it, the soil’s pH slides down. As acidity creeps up, certain crops start to struggle. Tomatoes, beans, and many herbs react poorly to sour soils. Good bacteria that keep soil balanced also lose ground in these conditions.

From what I’ve watched in farm trials, the issue isn’t a single dose—it’s routine use year after year. Repeated applications pull down soil pH region by region. I once visited a field that saw ammonium sulphate for three growing seasons. The pH dropped below 5.5, earthworms disappeared, and the owner had to spend extra money liming the land to recover what was lost. Research by agricultural agencies backs this up. According to the University of California, soils treated with ammonium sulphate need closer monitoring to avoid acidification over the years.

Testing, Balancing, and Responsible Use

It makes more sense to begin with a soil test before adding any fertilizer—commercial or homemade. Laboratories or even simple soil pH kits reveal what your ground really needs. If the reading sits in a good zone and crops look healthy, you might skip ammonium sulphate altogether or mix it with organic products for balance.

Gardeners who use this fertilizer swear by adding it in the right seasons. Early spring, when crops show nitrogen hunger, works best. Skipping doses during summer or after heavy rains keeps run-off and soil shifts in check.

Building Healthier Soil for the Long Haul

Farmers teach that soil acts like a living bank: what you put in must eventually pay back. Over-relying on ammonium sulphate hurts that balance. It’s smarter to rotate crops, use compost, and plant legumes—these replenish nitrogen naturally. Whenever I balance ammonium sulphate with compost or cover crops, my veggies respond more consistently and soil life stays strong.

Ammonium sulphate gives fast results but asks for care and planning. With soil testing, moderation, and attention to long-term soil health, it can fit safely into a gardener or farmer’s tool kit. Ignoring those steps, though, risks burning out the very life in the soil that plants need.

How is ammonium sulphate applied as a fertilizer?

Getting Nitrogen and Sulfur into the Soil

Having spent years around farmers, talking shop at local supply stores and walking the fields at planting time, you start seeing which fertilizers make real differences. Ammonium sulphate stands out, especially for growers who run into soils hungry for both nitrogen and sulfur. Walk over fields before spring corn or after a lush hay cutting—if the leaves show pale green or growth lags, there’s a good chance the ground is short on one or both of those elements. Without enough nitrogen, plants just won’t get that dark green color or bulk up to fill bins at harvest time. Missouri research showed that corn on nitrogen-deficient ground can lose as much as a third of its expected yield.

Some soils—especially sandy ones or those that see lots of rain—keep leaching sulfur out along with other nutrients. Ammonium sulphate helps fix these shortages because it delivers both nutrients in forms plants take up fast. After all, ammonium nitrogen offers less risk of washing away than pure nitrate, staying put a bit longer for roots to catch. Sulfate is right there, ready for roots to absorb straight away. For small-scale gardens or massive fields, that reliability counts more than any glossy brochure.

How the Product is Applied

You find ammonium sulphate bagged as a white or slightly greyish granule, sometimes a powder. Either way, it mixes easily with other dry fertilizers or gets spread on its own. In farm-scale operations, most folks use a simple broadcast spreader pulled behind a tractor. After grain is drilled or before the last pass over hay, they roll out the granules at a set rate, usually measured in pounds per acre. A spinner spins and the material lands across the field. In gardens or small plots, some use a hand-held scoop, gently flinging it beneath fruit trees, around cabbage rows, or across potatoes. Watering it in reduces losses, since it helps the ammonium absorb instead of gassing off in dry heat.

Growers often tractor it in before planting, letting a cultivator turn it several inches beneath the seedbed. Working ammonium sulphate under protects that nitrogen from sunlight, wind, and water. Side-dressing—applying it to existing crops along the rows—keeps corn, wheat, or sorghum fed when they need a midsummer boost, especially in poor soils where nutrients fail to reach later-growing roots. In recent years, researchers started warning about applying too much, since overly acidic soils can be a problem over time. That means routine soil testing has become as common as checking the oil in an old tractor—folks want to catch a problem before it hits the bottom line.

Balancing Smart Use and Environmental Impact

Extra nitrogen floating around doesn’t just disappear. It finds its way into water, either as nitrate or ammonia, and that’s a real headache in river basins across North America and beyond. Runoff pushes nutrients into lakes, causes algae blooms, and threatens drinking water. The best fix isn’t adding more chemicals or endless rules, but helping more people test their soil, learn how to calculate crop needs, and watch the weather so as not to spread right before a heavy rain.

Precision agriculture tools show promise. GPS-guided equipment can apply the right rate—no more, no less—down to a few feet. Coating technologies for slow release help, especially on sandy ground where nutrients otherwise rush away. The real key always comes back to education and experience—knowing the ground, respecting each field’s quirks, and listening to what the crop actually shows instead of chasing one-size-fits-all answers. Ammonium sulphate—simple, effective, and still requiring a sharp eye and a measured hand.

What is the recommended dosage of ammonium sulphate?

What Makes Ammonium Sulphate Special?

Ammonium sulphate often shows up in fertilizer discussions. Its formula delivers both nitrogen and sulfur, and these two nutrients push crops to grow better. I’ve seen fields turn green fast after farmers spread it in early spring. Sulfur sometimes gets overlooked, but crops like canola, wheat, and corn show visible hunger for it when it’s missing. Ammonium sulphate delivers a quick fix for both.

Recommended Dosage Isn’t a Guessing Game

Here’s where things get real: there’s no single answer for how much ammonium sulphate to use. Field, climate, soil type—each factor twists the answer. What works in one county leaves another farm short on yield. Still, crop specialists — and my own experience standing on Midwest farmland — suggest some typical ranges as starting points:

- Corn: 100 to 200 pounds per acre

- Wheat: 100 to 175 pounds per acre

- Soybeans: 75 to 150 pounds per acre (usually for sulfur supply)

These numbers show up again and again in extension bulletins and agronomy guides. They aren’t rules. They’re conversation openers, something for a grower to check against soil tests. An overdo can burn roots or waste money; limiting rates too much can stunt yield.

Soil Testing Sets the Baseline

My best seasons always followed a soil sample. Too much nitrogen without enough sulfur leaves crops looking sickly green, with pale leaves and stunted roots. Labs can read how much of each nutrient the soil is holding onto. If the test comes back showing low sulfur, ammonium sulphate becomes a smart addition. Most labs express sulfur in pounds per acre, and the right fertilizer dose fits the difference between soil reserves and what a crop will pull out.

University of Nebraska research highlights that, for corn, 20 pounds of sulfur per acre usually keeps plants healthy in sandy or low-organic soils. Since ammonium sulphate has about 24% sulfur and 21% nitrogen, a 100-pound application delivers about 24 pounds of sulfur—right in the target zone for many fields short on this nutrient.

Failures Teach Lessons Too

Over the years, I’ve watched neighbors load up double rates, expecting twice the yield. That backfires—salts build up and seedlings wilt. On the flip side, some wait too long, and yellow leaves show up before they react. Real improvement comes from finding the sweet spot for each field: regular testing, using banded rather than broadcast application in some soils, adjusting for irrigation or rain risks, and never skipping the numbers.

Better Results Call for Smarter Approaches

Crop advisors don’t hand out blanket recommendations; they check current field data and past performance. GPS mapping now tracks yields and pinpoints weak zones, allowing precise adjustments. Mixing ammonium sulphate with urea or other nitrogen sources can work well, especially in high rainfall zones where leaching strips nutrients away. Fields close to waterways deserve care—a buffer reduces runoff and keeps local streams clean.

The Path Forward

Using ammonium sulphate works best with thoughtful management—soil tests, realistic yield goals, matched timing, and a willingness to change as new data comes in. Every acre responds differently. Experience in the field and advice from trusted local experts usually beats any off-the-shelf chart. My advice: step back once in a while, check the evidence, and remember that next year’s soil health depends on today’s choices.

Are there any safety precautions when handling ammonium sulphate?

The Risks Hiding in the Bag

Ammonium sulphate isn’t just a white, powdery fertilizer—it's a compound that stings your nose and throat if you get too close without the right gear. Breathing in its dust irritates the lung lining and the eyes start to water. Every time I see someone shoveling fertilizer barehanded, I think back to a summer working on a landscape crew. Our boss never skipped handing out gloves and cheap dust masks even on the hottest days. One guy ignored the warnings—walked out of the storeroom coughing, his fingertips red and raw. That memory sticks. Hands, skin, and lungs don’t forgive careless contact with workshop chemicals.

Why Personal Safety Gear Matters

Factories packing ammonium sulphate hand out gloves and disposable overalls for a reason. The compound can trigger asthma symptoms, so any dusty air puts respiratory health on the chopping block. Respirators, splash goggles, and boots won’t win any fashion contests, but they stop problems before they start. Hospitals near fertilizer plants know the patterns: eye burns, sore throats, and skin rashes after people skip basic gear. Simple changes like always suiting up with gloves and never mixing the stuff with bare skin save plenty of doctor visits.

Avoiding the Classic Mistakes

Too many folks store bags of ammonium sulphate in damp sheds or stacked against leaky walls. Moisture turns the material into clumps and eventually leads to spills on the floor—a slip-and-fall drags a lot more risk in a warehouse than anyone expects. Closed, labeled containers in a dry spot cut that risk almost to nothing. In farm supply shops, chemical bins make separating ammonium sulphate from other products way easier. Last year, a blending accident north of the city highlighted what can go wrong when fertilizer dust crosses with bleach or lime—gases form that burn your lungs. Mixing without checking product compatibility isn’t just careless, it’s asking for trouble.

Respecting Fire and Water

Ammonium sulphate doesn’t light up on its own, but paired with enough heat from a fire, it decomposes and releases toxic gases like ammonia and sulphur oxides. I’ve seen firefighters refuse to walk past unlabeled barrels during barn fires. Anyone storing big quantities should mark their containers and train on-site crews for chemical emergencies, just like fire drills in schools. Runoff after spills matters too—streams next to fertilized fields catch excess sulphate and push fish to the surface gasping for air. That’s not just bad for nature, it’s a black mark against farms in the eyes of regulators and neighbors.

Solutions Worth Remembering

A few habits go a long way: only open ammonium sulphate bags outside or under good ventilation, lock personal protective equipment within reach, and leave nothing unlabeled. For big users, installing air scrubbers and offering refresher safety training keeps everyone alert. Signs in plain language, not just industry jargon, remind every hand—experienced or not—about handling steps. At home or on the job, keeping curiosity and caution linked is the difference between a healthy season and a trip to the ER.

Safety isn't just a checklist—it's choosing to care about everyone who shares the workspace, including future workers and neighbors downstream. With a little respect for a simple chemical, every bag of ammonium sulphate can do its job fertilizing fields without hurting anyone along the way.

| Names | |

| Preferred IUPAC name | diammonium sulfate |

| Other names |

Diammonium sulfate Mascagnite Actamaster Dolamin Ammate |

| Pronunciation | /əˌməʊniəm ˈsʌlfeɪt/ |

| Preferred IUPAC name | azanium sulfate |

| Other names |

Diammonium sulfate Ammonium sulfate Sulphuric acid diammonium salt Actamaster Dolamin |

| Pronunciation | /əˈməʊ.ni.əm ˈsʌl.feɪt/ |

| Identifiers | |

| CAS Number | 7783-20-2 |

| Beilstein Reference | 626017 |

| ChEBI | CHEBI:62906 |

| ChEMBL | CHEMBL1359 |

| ChemSpider | 10803 |

| DrugBank | DB09462 |

| ECHA InfoCard | 03b4a369-848f-4b94-80ff-8183627235a7 |

| EC Number | 231-984-1 |

| Gmelin Reference | 868 |

| KEGG | C01438 |

| MeSH | D018780 |

| PubChem CID | 6097028 |

| RTECS number | BQ8560000 |

| UNII | J6KZTLB9DV |

| UN number | UN3077 |

| CAS Number | 7783-20-2 |

| Beilstein Reference | IV 83 |

| ChEBI | CHEBI:62906 |

| ChEMBL | CHEMBL1357 |

| ChemSpider | 15252 |

| DrugBank | DB11110 |

| ECHA InfoCard | ECHA InfoCard: 027-024-00-6 |

| EC Number | 231-984-1 |

| Gmelin Reference | Gmelin Reference: "1701 |

| KEGG | C01737 |

| MeSH | D018503 |

| PubChem CID | 6097028 |

| RTECS number | BR6600000 |

| UNII | QF8C4B862G |

| UN number | UN3077 |

| Properties | |

| Chemical formula | (NH4)2SO4 |

| Molar mass | 132.14 g/mol |

| Appearance | White crystalline solid |

| Odor | Odorless |

| Density | 1.77 g/cm³ |

| Solubility in water | Highly soluble |

| log P | -4.75 |

| Vapor pressure | Negligible |

| Acidity (pKa) | pKa1 = 9.25; pKa2 = 1.99 |

| Basicity (pKb) | 3.95 |

| Magnetic susceptibility (χ) | Diamagnetic |

| Refractive index (nD) | 1.521 |

| Dipole moment | 0 Debye |

| Chemical formula | (NH4)2SO4 |

| Molar mass | 132.14 g/mol |

| Appearance | White crystalline solid |

| Odor | Odorless |

| Density | 1.77 g/cm³ |

| Solubility in water | Highly soluble |

| log P | -4.75 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 9.8 |

| Basicity (pKb) | 3.2 |

| Magnetic susceptibility (χ) | Diamagnetic |

| Refractive index (nD) | 1.521 |

| Dipole moment | 0 Debye |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 200.9 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -1181 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1180 kJ/mol |

| Std molar entropy (S⦵298) | 132.7 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | –1180 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1189 kJ·mol⁻¹ |

| Pharmacology | |

| ATC code | V04CX02 |

| ATC code | V04CX02 |

| Hazards | |

| Main hazards | Harmful if swallowed, causes serious eye irritation |

| GHS labelling | **"Warning, Exclamation mark, H315: Causes skin irritation, H319: Causes serious eye irritation, H335: May cause respiratory irritation"** |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315, H319, H335 |

| Precautionary statements | P264, P270, P273, P280, P301+P312, P305+P351+P338, P337+P313, P501 |

| NFPA 704 (fire diamond) | 1-0-0 |

| Autoignition temperature | > 454°C (849°F) |

| Explosive limits | Not explosive |

| Lethal dose or concentration | LD50 (oral, rat): 2840 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 2840 mg/kg |

| NIOSH | RN:10043-35-3 |

| PEL (Permissible) | 15 mg/m3 |

| REL (Recommended) | 10 mg/m³ |

| IDLH (Immediate danger) | Not established |

| Main hazards | Causes serious eye irritation. May cause respiratory irritation. |

| GHS labelling | Warning; Eye Irritation, Category 2; H319 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | Precautionary statements: P264 Wash hands thoroughly after handling. P270 Do not eat, drink or smoke when using this product. P301+P312 IF SWALLOWED: Call a POISON CENTER/doctor if you feel unwell. P330 Rinse mouth. |

| NFPA 704 (fire diamond) | Health: 1, Flammability: 0, Instability: 0, Special: - |

| Autoignition temperature | > 250°C |

| Lethal dose or concentration | LD50 oral rat 2840 mg/kg |

| LD50 (median dose) | LD50 (oral, rat): 2840 mg/kg |

| NIOSH | WS4250000 |

| PEL (Permissible) | 15 mg/m3 |

| REL (Recommended) | 10 mg/m³ |

| Related compounds | |

| Related compounds |

Ammonium nitrate Ammonium chloride Ammonium phosphate Ammonium sulfate nitrate Urea Potassium sulfate Calcium ammonium nitrate |

| Related compounds |

Aluminium sulfate Ammonium chloride Ammonium nitrate Ammonium persulfate Ammonium sulfite Potassium sulfate Sodium sulfate |