Ammonium Propionate: A Closer Look at a Versatile Compound

Historical Development

Discovering chemical preservatives changed the food and feed industries years ago. Ammonium propionate entered the scene in the mid-20th century, during a period when both grain storage and livestock feed safety faced major hurdles. Mold contamination was a big issue, leading to spoilage and animal health risks. Researchers at the time learned that propionates had powerful antifungal properties. Ammonium propionate started as a solution for preserving hay, silage, and grains, especially in places with high humidity where spoilage ran rampant. As chemical science moved forward, more applications surfaced, and its value stretched far beyond silage additives.

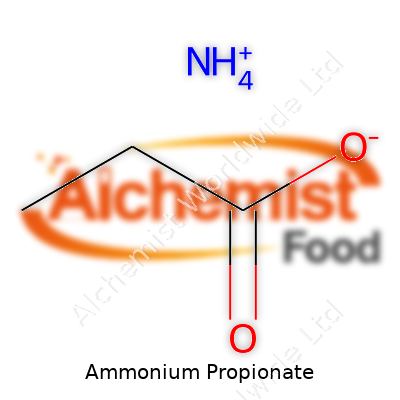

Product Overview

Ammonium propionate carries the chemical formula C3H7O2N. It’s a salt formed from propionic acid and ammonia. In practical terms, it looks like a white crystalline powder or sometimes a granular product. Companies package it in moisture-tight bags or drums. It's soluble in water, offering flexibility for both dry and liquid applications. Food and feed producers rely on it to extend product shelf life by knocking down yeast and molds. There’s a noticeable demand curve from the animal husbandry market, given its ability to safeguard feed without introducing harsh residues or off-flavors.

Physical and Chemical Properties

The appearance tends toward a white to off-white powder, with a slight odor reminiscent of its acid source. Ammonium propionate dissolves easily in water and shows moderate solubility in alcohol. It melts above 120°C, which means it stands up well to most regular storage and handling conditions. Its pH, once dissolved, sits on the slightly alkaline side, which matches up with its use in neutralizing acidic environments prone to fungal growth. Chemically, it stays stable under room conditions unless exposed to excessive heat or moisture for long spells.

Technical Specifications and Labeling

Manufacturers ship ammonium propionate with guarantees like a minimum 98% purity and low moisture percentages, generally below 2%. On every bag, labeling must mention batch number, date of production, and storage instructions, along with clear hazard symbols. Such standards don’t just help with traceability but also serve as checklists for buyers evaluating quality. Some labels now highlight compliance with major food and feed safety guidelines, such as meeting European Union or U.S. FDA regulations. Finer details, like recommended usage levels for feed, show up in technical datasheets supplied with each consignment.

Preparation Method

Most factories make ammonium propionate by neutralizing propionic acid with ammonia under controlled conditions. Inside a mixing vessel, controlled addition of gaseous or aqueous ammonia allows for a gentle reaction, minimizing runaway heat or gas emissions. Once the pH target is hit and all the acid consumed, crystallization or evaporation captures the solid product. Careful drying and sieving refine the powder, readying it for use or packaging. Waste streams, mostly water and traces of unreacted materials, undergo treatment before disposal or recycling into the process.

Chemical Reactions and Modifications

Ammonium propionate can participate in several reactions both in the lab and in practical settings. In the presence of strong bases or acids, it breaks down to release ammonia and propionic acid, which then exert antimicrobial actions. Heating triggers decomposition, where ammonia gas escapes, and the propionate base may further react. In some cases, chemical engineers convert it into other propionates for specialized shelf-life solutions or tweak the formulation by blending with synergistic preservatives to boost its effectiveness.

Synonyms and Product Names

The industry calls this compound by different names, including ammonium propanoate, ammonium dipropionate, and E284 (under EU food additive codes). Product labels often reference names like “propionic acid ammonium salt” or “feed-grade ammonium propionate.” Some companies market blends under proprietary trade names, though the core molecule stays consistent across offerings. Checking a product’s regulatory approvals and synonyms on packaging can help avoid confusion when swapping between suppliers or markets.

Safety and Operational Standards

Workers handling ammonium propionate need to pay attention to dust mitigation and ventilation. Safety standards recommend gloves and goggles to prevent direct skin or eye contact, reducing the risk of irritations. Spills call for prompt cleanup with plenty of water. Storage recommendations focus on dry conditions, sealed containers, and temperature control to keep clumping or decomposition at bay. Regulators in Europe, North America, and Asia-Pac all emphasize hazard communication, meaning clear warning labels and safety data sheets with every order. In routine use, it has a favorable safety profile when compared to harsher antimicrobial alternatives.

Application Area

Feed preservation drives a big chunk of ammonium propionate demand. Dairy operations use it to keep silage fresh, reduce dry matter losses, and ward off mycotoxins. Grain elevators and storage silos benefit from its ability to curb spoilage during long storage spans. The food industry also presses it into service as a preservative for baked goods, cheeses, and processed grains. Outside these sectors, specialty markets leverage its chemical reactivity for buffer solutions, fermentation nutrient mixes, and laboratory reagents. By spanning several sectors, the compound finds steady uptake in commercial-scale operations and smaller niche markets alike.

Research and Development

Recent research tracks both the compound’s antifungal potential and broader applications. Scientists have tested combinations that mix ammonium propionate with other organic acids to develop cost-effective, broader-spectrum preservatives. The feed industry funds plenty of work on optimizing dosage to balance mold inhibition with palatability and nutrient absorption for animals. Research into more efficient synthesis, including lower-energy production routes and byproduct minimization, continues in chemical engineering circles. On the food safety front, there’s focus on monitoring residual compounds in finished products to support tighter regulatory limits and address consumer concerns.

Toxicity Research

Long-term toxicity studies on ammonium propionate show a low-risk profile when used at normal concentrations for food and feed. Acute exposure might cause irritation but doesn’t trigger significant systemic effects in animals or people at practical doses. Regulatory reviews from European and U.S. bodies support its continued use, pointing to a lack of carcinogenic, mutagenic, or reproductive risks. Chronic feeding trials in animals back up the compound’s safety, tracking health markers like organ function, growth rates, and reproductive success. Nonetheless, up-to-date toxicity studies remain important because changes in manufacturing process or rising use levels could alter risk.

Future Prospects

Looking ahead, ammonium propionate’s prospects hinge on consumer attitudes toward chemical preservatives, regulatory frameworks, and advancements in animal nutrition. With sustainable farming taking priority, preservative compounds that leave little environmental or food chain footprint hold an edge. There’s movement toward natural or combined preservatives, yet reliable, affordable solutions aren’t easy to give up. More research into biodegradable packaging and smarter delivery forms—microencapsulation, for instance—could open new channels. On the regulatory front, regular safety reviews and innovation in residue detection will shape acceptance. From a practical standpoint, as feed and food security questions stay in the spotlight, ammonium propionate will keep pulling its weight as a dependable tool in the industrial toolkit.

What is Ammonium Propionate used for?

Keeping Animal Feed Fresh and Safe

Ammonium propionate might not get much attention outside of food science circles, but its impact reaches deep into the food and feed industry. This compound works as a preservative, helping to stop mold and bacteria from growing in animal feed. Anyone who has spent time on a farm, or even visited one, knows what a difference it makes to walk into a feed room and find that expensive grains have not spoiled into musty, useless lumps. Moldy feed threatens animal health, not just by ruining nutrition but also by introducing toxins. According to studies, propionate salts like ammonium propionate cut down on mold growth more effectively than traditional drying methods alone.

I remember visiting a dairy operation where feed storage sometimes felt like a race against moisture and time. Here, ammonium propionate showed its worth. Feed stayed palatable, animals ate well, and milk production was steadier. Losing fewer loads of feed means lower costs for the farmer and, ultimately, healthier livestock and safer products for people who buy them.

Helping in Food Preservation

In food processing, ammonium propionate shows up too. Bakeries and food manufacturers use it to slow down spoilage in baked goods. The science is straightforward: certain molds and bacteria need to be kept in check, or bread and pastries will go bad quickly, especially without refrigeration. This preservative lets food companies keep products on the shelf longer while protecting consumer safety.

Some shoppers worry about chemicals in food, and with good reason – ingredients deserve scrutiny. But here, the data gives a level of reassurance. Propionate compounds, including ammonium propionate, break down into substances the body can naturally handle. Regulatory agencies, including the US Food and Drug Administration and the European Food Safety Authority, have studied these preservatives for decades and set safe levels for their use.

Looking at Environmental and Practical Concerns

Safe preservation matters not just for product quality, but also for cutting food waste. Food waste brings environmental and economic headaches, piling up in landfills and wasting all the energy that went into production. Preservatives have a place in slowing this loss, provided companies use them responsibly and keep their processes transparent.

Of course, nothing replaces good storage practices. Improperly sealed bags, damp conditions, or long transport times all challenge preservatives. Based on my own work with agricultural producers, the best results come from a mix of additives and solid storage habits. This includes keeping feed dry, monitoring temperature, and rotating stock. No one product solves everything.

Potential Improvements and Future Directions

Consumer demand for natural food has grown, and with it, the search for alternatives to synthetic preservatives. Researchers are investigating plant extracts, better packaging, and improved distribution methods. Ammonium propionate, though, still fills a necessary role during this transition. If food and feed producers combine careful ingredient use with strict hygiene and solid storage, the end result brings safer products from farm to table.

The truth is, compounds like ammonium propionate often work quietly in the background, helping to keep food safer and fresher. While no solution is perfect, this one lifts a significant burden off both producers and consumers who want their meals and animal feed to meet the highest health and quality standards.

Is Ammonium Propionate safe for human consumption?

Getting to Know Ammonium Propionate

Most folks aren't familiar with ammonium propionate, but you’ve likely crossed paths with its chemical cousins in food labels. Used as a preservative, it helps prevent spoilage by slowing down the growth of mold and certain bacteria. Manufacturers turn to it mostly in the baking industry, keeping bread and other baked goods fresher for longer. This ingredient falls under the same umbrella as calcium and sodium propionate, both of which have been around for decades.

What the Regulators Say

The U.S. Food and Drug Administration (FDA) and international food safety bodies take a conservative approach to food additives. They’ve approved propionates, including ammonium propionate, for use under specific conditions. Food scientists have studied these chemicals for years, especially looking for links to toxicity or cancer. Results show low absorption in the digestive tract and rapid elimination—meaning the body doesn't hang onto it. The European Food Safety Authority (EFSA) reviewed the data in 2014, running detailed tests in animals and reviewing human exposure. They concluded the amounts used in food don't pose a health risk.

Real-World Safety Concerns

From what I’ve seen growing up in a family bakery, preservatives like this serve a real purpose—longer shelf life means less food waste and lower grocery bills. That said, folks worry about additives for a reason. Nobody wants mystery chemicals in their food. Current research on ammonium propionate’s safety hasn't found evidence of it causing harm in the amounts people consume. Reports of side effects are mostly tied to far higher doses than anyone would get from baked goods or snacks.

Why Trust Matters

Food safety boils down to trust. Companies won’t stick with ingredients that drive consumers away, but at the same time, nobody enjoys moldy bread. Transparency about what goes into food builds that trust. Clear information lets shoppers make up their own minds with all the facts on the table. Knowing that ammonium propionate has cleared safety reviews brings peace of mind. Still, everyone deserves the right to decide what they’re comfortable eating.

Looking Ahead

Science keeps moving, and so does our understanding of food. People want fresher food with fewer ingredients. Some bakeries and brands have started skipping propionates and putting more focus on natural preservation methods—think sourdough fermentation or innovative packaging. These approaches might not work for every situation or every price point, but they show that food companies pay attention when consumers speak up.

Tips for Making Informed Choices

Anyone concerned about preservatives has options. Reading labels closely and choosing brands with fewer additives can cut down exposure. Storing bread in the fridge or freezer gives a few extra days without chemicals. Baking at home means full control over every ingredient. If you’re worried about ammonium propionate or any other preservative, talk with a registered dietitian or look for independent food safety research from organizations you trust.As food culture changes and expectations shift, companies and regulators need to balance shelf life, safety, and transparency. That means ongoing research into the things we eat every day—whether familiar or not.

What are the storage and handling requirements for Ammonium Propionate?

The Real Stakes Behind Ammonium Propionate Storage

Ammonium propionate turns up in places where mold, bacteria, and fungus try to outwit folks working with animal feed, silage, and even some niche agricultural applications. To get real value from this compound, you’ve got to keep it out of trouble. Anyone who’s opened a bag of chemical that's gone lumpy or let moisture sneak in has seen firsthand how fast a product can go from useful to a sticky mess. In warm barns or feed mills, one careless moment can mean extra costs, waste, or—worse—mishaps that put people at risk.

Moisture Spoils Everything

Water finds its way into places you never expect. Ammonium propionate likes to pull in moisture from the air, so it clumps, loses flow, and can even start to break down. If storage gets sloppy, a pile of this powder turns solid as a brick or changes, so its mold-inhibiting kick takes a hit. I’ve seen storerooms where chemical bags split, contents stuck to each other, and no one ready for the haul to the mixer in the morning. Dry, cool, and sealed—those three rules stop things from falling apart. Polyethylene-lined bags or drums beat cardboard or thin sacks every single time.

Temperatures Make a Bigger Difference Than People Think

Heat sneaks up on you during the summer months. Even a corner storage room with poor airflow can turn into an oven by lunchtime. Hot, damp conditions spoil ammonium propionate long before you notice. The compound's not going up in flames, but changes in chemical activity mess with its shelf life. In a place like the Midwest or Southeast, temperature swings add to the headache. Keeping the powder in a temperature-stable room, away from direct sunlight, stretches its usable life and stops inventory from going stale.

Why Labeling and House Rules Matter

Mix-ups happen. A barrel without a clean label means someone grabs the wrong chemical, tossing risk into the mix, especially where food, feed, or kids might wander. Some warehouse mistakes lead to tragic outcomes, and stories of cattle feed contaminated by the wrong bag are not rare. Strict labeling, closed cabinets, and quick checks during inventory save hassle, money, and sometimes lives.

Personal Safety Never Came From Hoping for the Best

Ammonium propionate doesn’t blow up, but that doesn't make it harmless. Dust in the air can irritate lungs or eyes. Hands sweat inside gloves, masks slip down, and protective goggles feel like overkill—until someone gets a red, burning face. Basic gear—gloves, goggles, a dust mask—and a quick shower station nearby handle most problems before they turn serious. Cleaning up spills right away also earns its stripes. Sweep up the dust, mop it with plenty of water, and never leave piles in the corner where someone can track it all over the worksite.

Transport: The Forgotten Hurdle

Cars, trucks, and forklifts run over bumps. A leaky seal or split bag on the road turns into lost product and hard questions from inspectors. Strapping containers tightly, checking seals by hand, and never leaving a drum outside overnight beat insurance claims and sour customers. Every farm and feed mill benefits from simple habits: double-check your cargo, keep the truck bed clean, and never cut corners on a delivery run.

Final Word on Handling and Storage

Ammonium propionate serves people best when treated with everyday vigilance. Dry spaces, sturdy packaging, tight labeling, temperature checks, and personal protection turn a specialized chemical into a reliable tool—not a hidden liability. Skills picked up through bad experiences save a lot more headaches than just reading safety sheets and company memos.

What industries commonly use Ammonium Propionate?

Preserving Animal Feed

In the world of agriculture, feed spoilage hurts both smallholders and big operations. Ammonium propionate stands out as a reliable preservative for animal feed, especially silage and grain. Anyone who has dealt with moldy feed knows the smell and the waste that follows. Ammonium propionate tackles the growth of mold and bacteria, so more feed goes into animals and less ends up in the trash. That saves money, supports healthier herds, and trims down unnecessary strain on the farm budget.

Making Food Safer

Bread and baked goods have always fought the clock when it comes to freshness. Mold loves warmth, moisture, and carbs, so bakers have to use preservatives to keep loaves from spoiling before reaching the table. Ammonium propionate carries approval as a food additive in many countries, working quietly behind the scenes in commercial baking. The fact that regulators allow it tells me that safety reviews have been thorough, and bakers depend on it to reduce waste, keep food safe, and give customers quality they can trust. Food safety matters to everyone, not just industry, and this is one tool among many helping fill that gap.

Keeping Industrial Products in Shape

It’s not only food and feed where spoilage costs time and money. Leather goods, natural rubber, and some water-based paints need protection from fungi and mold too. Ammonium propionate plays a supporting role here, guarding these materials as they travel the long road from factory to final user. Skipping this step can lead to ruined shipments and financial loss for businesses without a huge safety net. Many companies, especially smaller ones, rely on dependable ways to protect their products from unseen risks like mold. That keeps prices steady and reputations strong.

Supporting Reliable Agriculture Practices

Over the last few decades, synthetic preservatives have earned criticism for environmental impact and health risks. Ammonium propionate breaks down safely in the environment, according to major safety data reviewed by regulatory agencies. Farmers and industry workers handling it trust that they aren’t trading one problem for another. Plus, with livestock feed prices rising globally, anything that stretches resources while keeping safety in mind deserves attention. Farmers tell me that a good preservative lets them store crops through tough seasons, so they aren’t forced to buy feed at the worst possible price.

Room for Smarter Solutions

A lot of discussion turns toward food waste and resource efficiency. More effective preservatives could have a big ripple effect. Ammonium propionate isn’t perfect, but it’s a useful tool as long as it’s handled responsibly. Some new research looks at blending it with other natural antimicrobials or using upgraded delivery methods. Honest conversations among scientists, regulators, and the industries using preservatives have to keep happening. This keeps food safer, reduces loss, and protects both the economy and the environment. As someone watching from both a consumer and food system perspective, it’s clear that small solutions matter in the bigger puzzle.

How does Ammonium Propionate act as a preservative?

Why Farmers and Bakers Rely on Ammonium Propionate

Wheat, corn, barley — these crops all face a real problem: mold. In damp fields or humid storage rooms, the battle isn’t only about weather, but about the microscopic world nobody sees until it’s too late. I’ve seen grain bins destined for the feedlot turn green on the surface just days after harvest. The loss stings, both in time and in money.

For feed producers and farmers, Ammonium Propionate steps in to keep things right. This chemical stops mold and bacteria from taking over animal feed and stored grains. Once added, it disrupts the setup that lets fungi or spoilage bacteria break out. Livestock feed lasts longer, and every bag that’s preserved means less waste, more profit, and healthier animals.

Digging into How It Works

Mold and spoilage don’t just happen because grains are wet; they rely on specific environments — especially neutral or slightly basic pH values. Ammonium Propionate upsets this balance. By making the storage area more acidic, it blocks key enzymes within mold and bacteria. These enzymes can no longer break down nutrients or reproduce properly, so the microbes stop spreading.

Smaller farmers used to fight spoilage with old tricks like sun-drying and salting. Now, Ammonium Propionate offers a more reliable guard. Shelf life goes up, and feed quality stays consistent. I’ve watched feed dealers shift away from bulk bin losses after switching to preservative treatments. Large commercial mills track storage times closely, and with propionate-treated stock, spoilage incidents drop off.

Why Food Safety Matters

The story isn’t only about extending shelf life or cutting costs. Some molds generate toxins called mycotoxins. Even small amounts can leave cows or chickens with digestive problems, or worse, enter our own food supply. These toxins survive heat and basic cleaning, so avoiding mold in the first place matters a lot more than trying to fix a contaminated batch later. Ammonium Propionate keeps the fungi out, and helps secure the food chain from farm to table.

Considering Health and Regulation

Plenty of consumers worry about chemical preservatives. In my experience, people scanning feed bag labels deserve straight answers. Ammonium Propionate breaks down quickly in the animal’s gut. Food safety authorities, including the US FDA and EFSA in Europe, review the research. Every approval links back to studies showing it doesn’t linger in meat, eggs, or milk. Livestock stay healthy, and families eating those products stay safe.

Looking for Practical Solutions

No preservative does the job alone. For any farm operation, successful storage means balancing moisture, temperature, cleanliness, and chemical aids like Ammonium Propionate. I’ve seen feedlots install new aerators, upgrade bin design, and train staff, then use propionate as a final layer of insurance. For home bakers and small farmers, smaller doses, paired with dry storage, deliver similar results.

Grain and feed will always be targets for spoilage, but chemistry, smart storage, and regular checks tilt the odds in our favor. Ammonium Propionate isn’t flashy, but its impact—less waste, healthier feed, safer food—matters every day in real barns and pantries.

| Names | |

| Preferred IUPAC name | Ammonium propanoate |

| Other names |

Ammonium propanoate Propionic acid ammonium salt |

| Pronunciation | /əˌmoʊniəm proʊˈpiːəneɪt/ |

| Preferred IUPAC name | Ammonium propanoate |

| Other names |

Ammonium propanoate Propionic acid ammonium salt Ammonium propionate salt |

| Pronunciation | /əˌmoʊniəm proʊˈpioʊneɪt/ |

| Identifiers | |

| CAS Number | 17472-44-9 |

| Beilstein Reference | 3520731 |

| ChEBI | CHEBI:63004 |

| ChEMBL | CHEMBL169782 |

| ChemSpider | 68213 |

| DrugBank | DB11276 |

| ECHA InfoCard | 18f2e107-d5a7-44a0-bbb2-d662038b0e83 |

| EC Number | 223-925-2 |

| Gmelin Reference | 58358 |

| KEGG | C18563 |

| MeSH | D02.241.081.599.138 |

| PubChem CID | 8677 |

| RTECS number | BV8400000 |

| UNII | 1NZ5F75G9D |

| UN number | UN2672 |

| CAS Number | 17472-14-9 |

| Beilstein Reference | 1733170 |

| ChEBI | CHEBI:63004 |

| ChEMBL | CHEMBL2105999 |

| ChemSpider | 48076 |

| DrugBank | DB14542 |

| ECHA InfoCard | 03b735f2-b118-45d9-9a13-969506c5a144 |

| EC Number | 223-748-8 |

| Gmelin Reference | 5569 |

| KEGG | C02437 |

| MeSH | D021242 |

| PubChem CID | 13396 |

| RTECS number | BR8750000 |

| UNII | ER2R8UXG1X |

| UN number | UN2902 |

| CompTox Dashboard (EPA) | DTXSID2021793 |

| Properties | |

| Chemical formula | NH4(C2H5COO) |

| Molar mass | 89.12 g/mol |

| Appearance | white crystalline powder |

| Odor | Ammonia-like |

| Density | 1.13 g/cm³ |

| Solubility in water | Very soluble |

| log P | 0.01 |

| Vapor pressure | < 0.01 mmHg (20 °C) |

| Acidity (pKa) | pKa ≈ 9.25 |

| Basicity (pKb) | 7.82 |

| Magnetic susceptibility (χ) | -47.0×10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.380 |

| Viscosity | Viscous liquid |

| Dipole moment | 4.98 D |

| Chemical formula | NH4C3H5O2 |

| Molar mass | 107.13 g/mol |

| Appearance | White crystalline powder |

| Odor | Ammonia-like |

| Density | 1.13 g/cm³ |

| Solubility in water | Soluble |

| log P | -0.08 |

| Vapor pressure | Negligible |

| Acidity (pKa) | pKa ≈ 9.24 |

| Basicity (pKb) | 8.77 |

| Magnetic susceptibility (χ) | -49.0e-6 cm³/mol |

| Refractive index (nD) | 1.420 |

| Viscosity | Viscosity: 20 cP (20°C) |

| Dipole moment | 3.91 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 176.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -505.5 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -206.7 kJ/mol |

| Std molar entropy (S⦵298) | 253.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -482.6 kJ/mol |

| Std enthalpy of combustion (ΔcH⦵298) | -1897.8 kJ/mol |

| Pharmacology | |

| ATC code | A01AB11 |

| ATC code | QG52AG10 |

| Hazards | |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H319: Causes serious eye irritation. |

| Precautionary statements | Store in a well-ventilated place. Keep container tightly closed. Wash hands thoroughly after handling. Wear protective gloves/eye protection/face protection. Avoid release to the environment. |

| NFPA 704 (fire diamond) | 1-0-0 |

| Lethal dose or concentration | LD50 (oral, rat): 1900 mg/kg |

| LD50 (median dose) | LD50 (median dose) of Ammonium Propionate: "4380 mg/kg (rat, oral) |

| NIOSH | NMAM 5026 |

| PEL (Permissible) | PEL: Not established |

| REL (Recommended) | 1500 mg/kg |

| Main hazards | May cause eye, skin, and respiratory irritation. |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Harmful if swallowed. Causes serious eye irritation. |

| Precautionary statements | P264, P270, P305+P351+P338, P337+P313 |

| NFPA 704 (fire diamond) | 1-0-0 |

| Lethal dose or concentration | LD₅₀ Oral Rat: 2450 mg/kg |

| LD50 (median dose) | LD50 (median dose): Rat oral 5000 mg/kg |

| NIOSH | Not Listed |

| PEL (Permissible) | 50 mg/m³ |

| REL (Recommended) | 1000-3000 |

| IDLH (Immediate danger) | Not listed |

| Related compounds | |

| Related compounds |

Ammonium acetate Ammonium butyrate Ammonium formate Ammonium lactate Ammonium chloride |

| Related compounds |

Ammonium acetate Ammonium butyrate Ammonium lactate Sodium propionate Potassium propionate Propionic acid Ammonium formate |