Aluminium Ammonium Sulfate: A Closer Look at Its Relevance and Future

Historical Development

Diving into the story of aluminium ammonium sulfate means revisiting the roots of industrial chemistry. Chemists found themselves drawn to double salts like this as they searched for ways to harness nature's raw resources. For centuries, potassium alum served people well in tanning, dyeing, and water purification, but as the world industrialized, alternative alums pulled into focus. Around the late 19th to early 20th century, researchers sought a less costly substitute for potassium, which led to ammonium alum stepping into the frame. Its recipe called for aluminum sulfate and ammonium sulfate, both of which could be sourced with expanding mining and chemical industries. That shift reflected broader changes—an expanding demand for chemical raw materials, improvements in extraction techniques, and a mounting interest in process efficiency. Factories integrated this compound into a fast-growing catalog of industrial chemicals, bringing lasting change to sectors like leather tanning and papermaking.

Product Overview

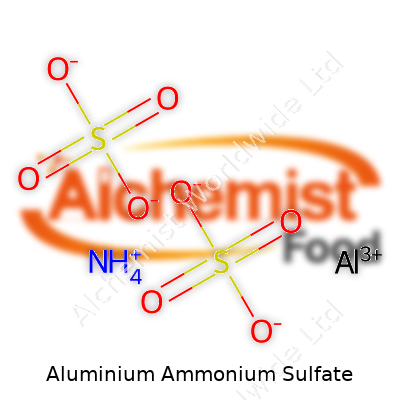

Aluminium ammonium sulfate, also recognized in industry circles as ammonium alum, carries the chemical formula NH4Al(SO4)2·12H2O. Its crystalline nature and water solubility didn’t just happen to suit manufacturing; these features carved out a niche across countless industrial and laboratory settings. People know it for purifying water, for making dyes cling to textile fibers, for helping leather toughen up, and for acting as an astringent in cosmetics. Its role traces back to one core property—a knack for precipitating proteins and helping particles settle out of solution. That’s the reason aluminium ammonium sulfate finds a loyal following in both longstanding and emerging industries, offering value that crosses over from the workshop to the research bench.

Physical & Chemical Properties

Out of the bag, aluminium ammonium sulfate takes the form of large, transparent crystals. Those who have worked with the substance recognize the faint, acidic tang drifting up from its granules. Each molecule brings together aluminum ions, ammonium ions, and sulfate ions, all tied together with twelve water molecules as part of the crystalline structure. It melts at about 94°C, and it breaks down fully with hot water. Acids dissolve it easily, which gives it an edge in many laboratory and technical applications. It doesn’t burn but decomposes under strong heat, giving off ammonia and sulfur oxides—an important point for both lab workers and industrial operators. Magnetic and optical qualities won’t spark much excitement among technologists, but its reactivity with bases and some reducing agents lands it squarely in the toolkit of water treatment engineers and chemical manufacturers.

Technical Specifications & Labeling

Industry standards outline clear requirements for aluminium ammonium sulfate. Purity often measures above 99%, a crucial measure since impurities can muddy results in sensitive settings. Technical grade and reagent grade hold different places: the former for large-scale processes, the latter for laboratory and pharmaceutical needs. Labeling rules set by agencies like OSHA and the European Chemicals Agency include chemical name, formula, hazard classification, and handling advice. These regulations aren’t arbitrary; they grow out of hard-won experience, learning from cases where ambiguous labeling led to mishandling or accidents. The precise information on any drum—lot number, batch, manufacturer, expiration—signals a commitment to safety and traceability. That’s a non-negotiable in environments where mix-ups can cost productivity, health, or even life.

Preparation Method

People have streamlined the preparation of aluminium ammonium sulfate for over a century. Manufacturing starts with dissolving aluminum sulfate and ammonium sulfate in warm water. The solution cools slowly, allowing crystals to form as water evaporates. Operators adjust concentrations and temperatures to get the right crystal size—fine powders for speedy solubility, bigger chunks for slow-release use. Filtration and washing remove impurities, followed by air-drying. Many remember the industrial smells and sheer scale of it—racks of crystals, trace ammonia in the air. In smaller-scale labs, crystallization plays out in glass beakers, the process as much about patience as technique. Shifts toward greener manufacturing have encouraged recycling of process water and tighter emissions controls, reflecting a sense across the sector that chemical operations can stand to balance output with responsibility.

Chemical Reactions & Modifications

Aluminium ammonium sulfate doesn’t take up a major spot in synthetic organic chemistry, but it shines in fields needing mild acidity and gentle astringency. Add it to water and it dissociates completely: ammonium and aluminium ions scatter through the solution, sulfate settles in as a stabilizer. Blend it with strong bases and you watch aluminum hydroxide precipitate, followed by ammonia gas escaping as the pH climbs. In environmental chemistry, it reacts with phosphate and organic matter, pointing the way to water purification and sludge stabilization. Material scientists have explored modifying ammonium alum by swapping out sulfate or tweaking the cationic partners—one result, the creation of specialty alums for high-tech applications like ceramics or electronics. Each new combination brings changes in solubility, heat stability, or reaction with pollutants, providing practical levers for those developing niche materials.

Synonyms & Product Names

Aluminium ammonium sulfate wears several nametags, depending on local custom and industry tradition. Ammonium alum, ammonium aluminum sulfate, and Alum, ammonium are all recognized names. Registries like the Chemical Abstracts Service use identifiers like CAS 7784-26-1, and EINECS adds its own cataloging with code 233-375-1. Some catalogs use tags like “Food Grade Alum” or “Tanning Alum,” though those names vary by geography and application. Within the dyehouse or the waterworks, the short-hand ‘alum’ stands in for a range of double sulfate salts, but those on the technical side quickly learn to clarify which cation sits alongside aluminum. These names matter greatly in procurement and compliance, where a mix-up can derail an entire production run.

Safety & Operational Standards

Direct experience drilling safety protocols into plant workers and technical staff makes clear that complacency around chemicals like aluminium ammonium sulfate leaves people open to risk. Inhalation, dust in the eyes, or skin contact gives rise to irritation—most operators keep gloves, goggles, and dust masks at the ready. Swallowing even moderate amounts brings on nausea and abdominal pain, leading regulatory bodies to call for proper labeling and access to safety data sheets. Storage involves sealed containers, away from moisture and incompatible substances like strong bases. Spill management focuses on immediate cleanup, neutralization with lime or soda ash, and ventilation. Strict adherence to OSHA, REACH, and local environmental laws protects teams and communities, and every incident report underscores the wisdom in these hard-earned rules.

Application Area

Years spent working alongside operators and engineers in papermaking and water treatment leave little doubt about aluminium ammonium sulfate’s value. In the waterworks, a dose of this salt clears murky water fast, as suspended particles clump together and settle out. Paper manufacturers count on it to strengthen paper by helping fibers bind and laying down minerals that boost whiteness. Dyeworks trust it as a mordant, locking color into fabric under steam or pressure. Leather tanners appreciate its astringency, which readies hides for further treatment and cuts bacterial growth. Even the food industry, with its tough safety rules, has found a place for ammonium alum as a pickling additive that keeps vegetables crisp. Some cosmetic producers still use it for aftershaves and styptic pencils—the sting and quick clotting of minor nicks a familiar experience to many. Across all these uses, the same qualities shine through: clarity, stability, and a helping hand in controlling unwanted reactions.

Research & Development

Looking at the research landscape, efforts intensify around smart uses and sustainability. Water engineering teams explore how to minimize residual aluminium in treated water, knowing that consumer safety standards keep tightening. Material researchers tinker with alum matrices to tailor porosity and create catalysts for environmental cleanup. Biologists review how ammonium alum modulates proteins, aiming to refine food processing steps or develop new biomaterials with useful cross-linking properties. Recovering aluminium and sulfate from industrial wastewater points the way to more circular use—a rising demand as chemical plants face scrutiny over emissions and by-product disposal. These research efforts come from a mix of curiosity and pressure to meet ever-higher safety and efficiency standards.

Toxicity Research

Toxicologists and environmental scientists keep a critical eye on aluminium ammonium sulfate for good reason. Swallowing large amounts causes stomach and intestinal irritation, and chronic exposure among factory workers has spurred efforts to limit airborne dust with better ventilation and enclosure technology. Most environmental guidelines set low thresholds for aluminium in drinking water, driven by research into its possible links with neurodevelopmental and kidney effects. Animal studies paint a nuanced picture—high doses matter, chronic low-level exposure brings more questions than easy answers. For aquatic life, discharge of ammonium alum into rivers creates the risk of pH shifts and aluminum toxicity, pushing plant managers to treat effluent thoroughly before release. Toxicity data don’t stoke fear, but they press the case for respect and rigor in handling, especially in places where people and ecosystems come closest to chemical operations.

Future Prospects

The road ahead hints at both stability and innovation. Water infrastructure in aging cities will rely on time-tested chemicals like ammonium alum but expect engineers to trim costs, cut waste, and raise safety margins. Biotech and advanced materials stand ready to use this double salt in new guises—maybe as a controlled-release ingredient, a template for nanomaterials, or a low-cost purifying agent in developing regions. Regulatory agencies will keep tweaking limits as evidence accumulates on environmental persistence or cumulative exposure. Industrial chemists face high expectations on resource use and green chemistry practices, fueling efforts to recycle and reinvent legacy materials. Anyone working on the frontlines of manufacturing knows that small shifts in product specs ripple through supply chains and finished goods—aluminium ammonium sulfate carries a legacy and a future, shaped by the choices of those who work with it, regulate it, and depend on its unique blend of properties.

What is Aluminium Ammonium Sulfate used for?

The Everyday Uses in Our Lives

Aluminium ammonium sulfate doesn’t usually show up in headlines, but dig a bit and you’ll see traces of it running through daily routines in surprising ways. Most folks call it “ammonium alum.” It works behind the scenes in food, personal care, water treatment, and even gardening. Over time, a few run-ins with this compound showed how something unfamiliar by name can shape ordinary living.

Where It Shows Up in the Kitchen and Home

Home bakers bump into ammonium alum every now and then. It pops up as a pickling agent, giving those crunchy cucumber slices that familiar texture and snap. The compound helps fruits and veggies hold on to color and structure during pickling. Without it, pickles turn mushy. Food scientists refer to ammonium alum as E523, and regulatory bodies throughout Europe and Asia rate it safe for use in moderate concentrations. Extensive research published in the Journal of Food Science points to minimal toxicity when consumed at typical household levels.

The powder also drifts into baking. Pastry chefs lean on it as part of double-acting baking powders to give dough that needed lift. Walk into a bustling bakery, you might catch bakers dusting aluminum ammonium sulfate over batches of dough, chasing that balance between fluff and stability.

Water Purification: Keeping Drinking Water Clear

Clean water seems simple, but turning river sludge into a clear glass on the kitchen table takes careful chemistry. Water treatment facilities add ammonium alum to pull dirt and contaminants together so they settle out. It gathers minute particles into clusters big enough to skim away—keeping water safe for families and for agriculture. According to data from the World Health Organization, coagulants like ammonium alum have cut waterborne diseases significantly in countries that use modern purification methods.

Cosmetics, Textile, and Beyond

The compound turns up again in deodorants and antiperspirants, where it tampers down body odor and sweat by tightening pores. Folks exploring natural personal care look for “alum stones,” which push away bacteria without heavy perfumes. The cosmetics industry needs to keep a close eye on concentrations here. The U.S. Food and Drug Administration closely monitors additives in skin care, and published safety reviews show no major risk for skin use at common levels.

Clothing and craft benefit, too. For centuries, dyers have dipped fabrics in ammonium alum solutions, fixing vivid color without fading. Museums rely on this process to restore historic garments and tapestries, locking fiber colors in for decades.

Considering Environmental and Safety Questions

No chemical is perfect. Some concerns stem from overuse and runoff, especially in water treatment and agriculture. Small farms and local governments now watch waste levels, since too much sulfate in water systems can upset local ecosystems. Scientists working with the Environmental Protection Agency point to the need for tighter process controls and recycling of water treatment byproducts. A realistic step, in my experience, means backing regular audits and encouraging industries to treat spent solutions onsite before dumping anything downstream. For families and home cooks, moderation remains the safest approach—using ingredients as intended and keeping storage containers sealed and labeled.

Aluminium ammonium sulfate serves all sorts of purposes with meaningful impact. Look past its dry, chemical name, and it connects food, health, and public safety in practical, everyday ways.

Is Aluminium Ammonium Sulfate safe for consumption?

What Is Aluminium Ammonium Sulfate?

Aluminium ammonium sulfate, often called ammonium alum, finds its way into food processing and water treatment. It works as a firming agent and rises on the ingredient lists of pickles, baking powder, even some jellies. For most people, it's just another complicated-sounding name on a label—easy to skim over but worth a closer look.

Regulation and Scientific Background

Both the US Food and Drug Administration and the European Food Safety Authority have rules for aluminium ammonium sulfate in food. The FDA lists it under “Generally Recognized As Safe” (GRAS) for specific, limited uses. The European Food Safety Authority reviewed the safety data and set an acceptable daily intake for aluminium from all sources, including food additives like this one.

Data shows that our bodies don’t absorb much aluminium from food. Studies estimate that less than one percent of aluminium taken in by mouth makes its way into the bloodstream. The rest exits through the digestive tract. The kidneys quickly filter absorbed aluminium, pushing it out through urine. People with healthy kidney function usually don’t keep much aluminium in their bodies from food.

Why People Worry

Some headlines link aluminium with health concerns—especially around brain health and diseases such as Alzheimer’s. The research here isn’t simple. Large-scale studies haven’t nailed down a solid link between dietary aluminium or the use of substances like aluminium ammonium sulfate and major health problems in healthy people. Animal tests giving high doses sometimes show damage, but those amounts far exceed what any ordinary diet would provide. Real-world eating habits keep levels low.

One real-life story stays with me—a friend whose grandmother used old-school aluminium cookware for decades, adding alum powder to her pickles every summer. She reached her late nineties still sharp as ever. Of course, that’s just one story, but it lines up with what scientists see: average diets lead to very low exposure.

Hidden Risks—Who Should Pay Attention?

Folks with kidney disease stand out as a group who should take care. Damaged kidneys don’t clear aluminium well, so even small daily exposures might add up. Individuals with rare genetic troubles processing metals may also want to check with a doctor. For most people, small amounts used in foods or as a baking ingredient cause no trouble. That said, anyone thinking of taking “alum” powders as supplements or in large, concentrated doses for claimed health boosts should look at the evidence. There’s no proven reason to do so, and lots of unknowns.

Toward Better Choices

Reading ingredient labels stays important. Homemade pickles can turn out crisp without added alum—try grape leaves or more traditional methods. If concern lingers, look for foods that skip aluminium-based additives. Parents may want to limit processed foods for kids when possible, since children have smaller bodies and might be more sensitive to heavy metals in general.

Ultimately, the science tells a consistent story. Used in moderation, as it is in most foods, aluminium ammonium sulfate doesn’t pose a danger to healthy people. Staying informed and making choices that work for one’s family brings peace of mind, which sometimes counts just as much as any regulation.

What is the chemical formula of Aluminium Ammonium Sulfate?

Getting to the Heart of the Matter

Aluminium ammonium sulfate goes by another name—ammonium alum. People might recognize it more from uses in water purification, pickling, or textile dyeing than from staring at a blackboard full of chemical equations. In the lab, you find its chemical formula written as NH4Al(SO4)2·12H2O. Behind this string of letters and numbers lies a combination important for much more than stubborn science quizzes.

Breaking Down the Formula

Looking closely, the formula tells you ammonium (NH4+), aluminium (Al3+), and sulfate (SO42–) ions all join forces in a single crystalline unit. Those water molecules—twelve per every molecule of alum—tie the structure together as hydration. In real-world terms, this keeps the salt stable and easy to use in all sorts of applications where old-school metal compounds might lose their touch. That water can leave if heated, but for most purposes, the entire hydrated molecule stays intact.

The Rooms Where Alum Gets to Work

I’ve watched alum crystals grow in an old coffee jar, and the sharp, glassy shapes stick in memory: it’s not just for chemistry class, either. Potassium alum often enters the elementary school crystal-growing contests, but aluminium ammonium sulfate holds its own in the professional world. Water purification plants rely on alum salts to clear up cloudy water. Sulfate ions cause little particles and organic junk to clump up so they can be filtered away. Knocking the mud and bacteria out of water drops the risk of illness—which matters if clean drinking water isn’t a given.

Pickling turns up as another surprising corner for ammonium alum. Adding this compound helps keep veggies crisp. Think cucumbers pulled from the brine with a satisfying crunch—in part, alum prevents the mushy fate so many home canners dread. While questions have come up about ingesting certain additives, the U.S. Food and Drug Administration sees small, regulated use as safe.

In the Dye House and Beyond

Textile workers lean on alum’s properties, too. Dyeing fabrics calls for what chemists call a “mordant,” something that locks color into cloth instead of letting it fade after the first wash. Alum helps fix the dye so classic colors last. Anyone who’s watched their favorite shirt turn gray after a handful of washes can appreciate the chemistry in action. This chemistry doesn’t just stay in old-fashioned workshops—modern dyeing still makes use of alum compounds around the world.

Room for Improvement and Responsible Use

Large-scale industrial use of aluminium ammonium sulfate brings a responsibility: what happens once the wash water or the leftover solution flows down the drain? Aluminium compounds, in high concentrations, can cause environmental concerns, including harming aquatic life or soil quality. Some cities already test tap water for aluminium content, based on World Health Organization benchmark safety levels.

It makes sense to look for ways to recycle or treat alum solutions after their primary use. That could mean new filtration techniques or chemical processes that pull the aluminium out before it hits the environment. Researchers and chemical engineers continue to look for greener options—turning experience and new science into safer water, food, and textiles.

A Final Word on Getting It Right

Getting to know the formula for aluminium ammonium sulfate—NH4Al(SO4)2·12H2O—opens up a world of connections. It’s more than dusty lab supplies; it shapes what we eat, wear, and drink every day. Each use comes with a tradeoff, but knowledge and care can make all the difference.

How should Aluminium Ammonium Sulfate be stored?

Understanding What’s In The Bag

Most people won’t spot aluminium ammonium sulfate by name unless they work in a lab, garden, or food business. Found in fertilizers and pickling solutions, this white crystalline substance doesn’t jump out as dangerous, yet it deserves a bit of respect. Looking back at my time handling chemicals in university stores, I remember barrels lined up—labels bold, with instructions drilled into us until it stuck. My mentor often said: “Respect the material, not the label.” Aluminium ammonium sulfate proves that point. It might not burn or explode, but it still poses risks if handled carelessly or stored poorly.

Why Cool, Dry, And Sealed Makes All The Difference

Moisture turns this salt into a mushy, unstable mess. If water creeps into a poorly sealed bag, clumping starts fast, and, in humid places, mold can show up. No one enjoys scraping a once-useful powder from the bottom of a soggy box. Wherever I’ve worked, I always kept chemicals in sturdy, resealable containers, stashed above floor level. Metal shelves beat wood, since spills or leaks can’t seep in and cause a bigger headache down the line.

Direct sunlight is an enemy too. Heat leads to breakdown, and sunlight pushes stray reactions that never go well. Even for an apparently stable powder, direct heat or sun speeds up wear and, eventually, messes with both safety and effectiveness. Basements or supply closets do the trick, as long as they stay dry and cool.

Chemical Conversations: Compatible Neighbors Matter

I’ve seen careless mistakes—it’s all too easy to gather similar-looking powders on the same shelf, but mixing up storage for aluminium ammonium sulfate and, say, strong acids or bases invites trouble. With acids, for example, there’s a risk of unexpected chemical reactions. Mixing up containers after a rushed shift once led a coworker to endure a wheezy night from accidental gas exposure. Ever since, I always separate chemicals physically by group—even if labels say “incompatible,” physical barriers beat good intentions.

Labeling: The Small Cost That Pays Off

Clear labels aren’t just busywork. In busy environments, someone always grabs in a hurry. Good labeling—large font, clear warnings, date of arrival—stops mistakes. Even after a year, visible instructions remind everyone what to do if a spill happens or if a breach shows up.

Spill Response Readiness

Plenty of incidents stem from spilled powder. Slips, skin contact, and even minor inhalation can spark trouble. The right spot for storage keeps the material clear of major walkways. A simple spill kit nearby with gloves, scoop, and sealable bags contains small accidents before they grow. I’ve dealt with spills, and quick action means fewer problems, shorter cleanups, and less paperwork.

Regulations And Long-Term Wisdom

Rules back up most of what experience teaches. Storage away from food and drink stands as a must after repeated lessons from accidental mixing at home and in school labs. Some states expect annual checks—something I always did with a printout and highlighter. Catching cracks in containers or forgotten old stock saves money and stress.

Simple Steps, Fewer Surprises

In the end, storing aluminium ammonium sulfate doesn’t call for fancy tools. What matters is a dry, cool place, sealed containers, good separation from potential chemical foes, and alerts to errors before anyone pays the price. I’ve learned that small, careful steps offer the cheapest, safest results—and cut headaches better than any after-the-fact cleanups.

What are the hazards or safety precautions for Aluminium Ammonium Sulfate?

Understanding This Compound

You’ll spot Aluminium Ammonium Sulfate sometimes called ammonium alum—a white, crystalline salt. Some folks use it in water purification, pickling, dying fabrics, or even as part of baking powder. The name sounds technical, but you probably brushed up against it in school science class or read it near the bottom of a garden product label. Even so, being familiar doesn’t mean forgetting its hazards.

Hazards in Daily Use

Aluminium Ammonium Sulfate rarely acts alone. It brings risks once someone gets careless. If it gets in your eyes, redness and irritation can show up fast. Getting it on your skin sometimes leads to rashes or itching. Nobody wants a spoonful in their breakfast, either; swallowing this compound leads to nausea or abdominal cramps. I remember a friend joking about lab chemicals looking like sugar in jars. He learned the hard way—they may be white and grainy, but they’re no kitchen product.

Inhaling its dust creates another problem. The small particles bother the nose and lungs. People sometimes notice a dry cough or chest tightness. Exposure in small amounts might not seem like much, but over time, repeated contact builds up irritation and discomfort. That wakes you up to the reality: it’s safer to treat every chemical, even familiar ones, with respect.

My Experience with Lab Protocols

In high school science, my chemistry teacher hammered in the basics. Gloves stand between you and a rash. Goggles save you from an eye wash station panic. That early experience stuck with me. I saw what happened if someone ignored those simple steps—even the “harmless” stuff bites you back. One day, a classmate spilled aluminium ammonium sulfate. The sharp, astringent smell made everyone cough. We all learned that opening a bag of chemicals without thinking could ruin your afternoon.

Staying Out of Trouble

Safety starts with easy steps. A dust mask keeps your airways comfortable, especially when measuring out powders. Working in a spot with good airflow means you’re not breathing in stray dust. Washing your hands after handling any lab salt cuts down on a trip to the nurse. Never taste or smell something directly from the container—those little warnings aren’t for show.

The big factories need even stricter routines. They store bulk chemicals in tightly sealed bins and put up clear labels everywhere. Emergency showers and eyewash stations aren’t just for show. Regular safety drills make sure everyone remembers the quickest way to clean up in a bad moment. At home, you won’t need all of that, but tight containers and keeping chemicals out of reach from kids can prevent accidents.

Smart Storage and Disposal

Throwing leftovers down the drain doesn’t fly. Some water treatment plants don’t handle these salts, so dumping them can damage ecosystems. I’ve dropped off unused chemicals at local hazardous waste pickups instead. If a place handles batteries and paints, they’ll probably know what to do with old lab salts, too.

None of this is about being afraid of science. It’s about building habits that keep chemists, gardeners, and anyone who’s curious out of harm’s way. The right gear, common sense, and respecting even simple-looking compounds keep the day safe and drama-free.

| Names | |

| Preferred IUPAC name | aluminium ammonium sulfate |

| Other names |

Ammonium alum Ammonium aluminum sulfate Alum Ammonium alum sulfate Diammonium aluminum disulfate |

| Pronunciation | /ˌæl.jʊˈmɪn.i.əm əˈmoʊ.ni.əm ˈsʌl.feɪt/ |

| Preferred IUPAC name | aluminium ammonium sulfate |

| Other names |

Ammonium alum Ammonium aluminum sulfate Ammonium alumina sulfate |

| Pronunciation | /əˌluːmɪnɪəm əˈməʊniəm ˈsʌlfeɪt/ |

| Identifiers | |

| CAS Number | 7784-26-1 |

| 3D model (JSmol) | `Al3.0H16.0N2.0O16.0S2.0` |

| Beilstein Reference | 391989 |

| ChEBI | CHEBI:32599 |

| ChEMBL | CHEMBL1201561 |

| ChemSpider | 22860 |

| DrugBank | DB11136 |

| ECHA InfoCard | 100.018.208 |

| EC Number | 233-135-0 |

| Gmelin Reference | 6046 |

| KEGG | C14137 |

| MeSH | D000467 |

| PubChem CID | 24856 |

| RTECS number | BQ9625000 |

| UNII | V9B58N7Y1B |

| UN number | UN3077 |

| CAS Number | 7784-26-1 |

| 3D model (JSmol) | `Al3d JSmol model: "Al2(SO4)3·(NH4)2SO4"` |

| Beilstein Reference | 35380 |

| ChEBI | CHEBI:32599 |

| ChEMBL | CHEMBL1201107 |

| ChemSpider | 25935 |

| DrugBank | DB15704 |

| ECHA InfoCard | ECHA InfoCard 100.013.815 |

| EC Number | 233-135-0 |

| Gmelin Reference | 13777 |

| KEGG | C18624 |

| MeSH | D000466 |

| PubChem CID | 24856 |

| RTECS number | BA1925000 |

| UNII | Q7C9Y6UL5C |

| UN number | UN3077 |

| CompTox Dashboard (EPA) | DJ40RVT93L |

| Properties | |

| Chemical formula | NH4Al(SO4)2·12H2O |

| Molar mass | 453.33 g/mol |

| Appearance | White crystalline powder |

| Odor | Odorless |

| Density | 1.64 g/cm³ |

| Solubility in water | Soluble in water |

| log P | -4.38 |

| Vapor pressure | Negligible |

| Acidity (pKa) | ~3.0 (for the hexaquo ion) |

| Basicity (pKb) | 8.8 |

| Magnetic susceptibility (χ) | +18.5·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.466 |

| Dipole moment | 0 D |

| Chemical formula | NH4Al(SO4)2·12H2O |

| Molar mass | 453.33 g/mol |

| Appearance | White crystalline solid |

| Odor | Odorless |

| Density | 1.645 g/cm³ |

| Solubility in water | soluble |

| log P | -4.34 |

| Vapor pressure | Negligible |

| Acidity (pKa) | 9.6 |

| Basicity (pKb) | 8.8 |

| Magnetic susceptibility (χ) | +22.0·10⁻⁶ cm³/mol |

| Refractive index (nD) | 1.452 |

| Dipole moment | 0 D |

| Thermochemistry | |

| Std molar entropy (S⦵298) | 281.5 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | −4030 kJ/mol |

| Std molar entropy (S⦵298) | 155.8 J·mol⁻¹·K⁻¹ |

| Std enthalpy of formation (ΔfH⦵298) | -4140 kJ/mol |

| Pharmacology | |

| ATC code | A12AB01 |

| ATC code | A12AB01 |

| Hazards | |

| Main hazards | Irritating to eyes, skin, and respiratory tract |

| GHS labelling | GHS07, GHS09 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | Hazard statements: "Causes serious eye irritation. |

| Precautionary statements | P264, P270, P280, P301+P312, P330, P501 |

| NFPA 704 (fire diamond) | Health: 2, Flammability: 0, Instability: 1, Special: - |

| Lethal dose or concentration | LD50 oral rat 6207 mg/kg |

| LD50 (median dose) | LD50 (median dose): Oral-rat LD50: 6207 mg/kg |

| NIOSH | GN0100000 |

| PEL (Permissible) | PEL (Permissible Exposure Limit) for Aluminium Ammonium Sulfate: "10 mg/m3 (as Al, OSHA) |

| REL (Recommended) | 10 mg/m3 |

| Main hazards | Causes skin and eye irritation, may cause respiratory irritation. |

| GHS labelling | GHS05, GHS07 |

| Pictograms | GHS07 |

| Signal word | Warning |

| Hazard statements | H315: Causes skin irritation. H319: Causes serious eye irritation. H335: May cause respiratory irritation. |

| Precautionary statements | P261, P264, P271, P272, P273, P280, P302+P352, P305+P351+P338, P312, P321, P332+P313, P362+P364, P501 |

| NFPA 704 (fire diamond) | Health: 2, Flammability: 0, Instability: 1, Special: - |

| Lethal dose or concentration | LD50 oral (rat) 4287 mg/kg |

| LD50 (median dose) | LD50 (oral, rat) = 6207 mg/kg |

| NIOSH | Not Listed |

| PEL (Permissible) | Not established |

| REL (Recommended) | 3 mg/m³ |

| IDLH (Immediate danger) | Not listed |

| Related compounds | |

| Related compounds |

Aluminium sulfate Ammonium sulfate Potassium alum Sodium alum Chrome alum Ferric alum |

| Related compounds |

Aluminium potassium sulfate Aluminium sodium sulfate Ammonium iron(III) sulfate Ammonium sulfate |